|

|

|

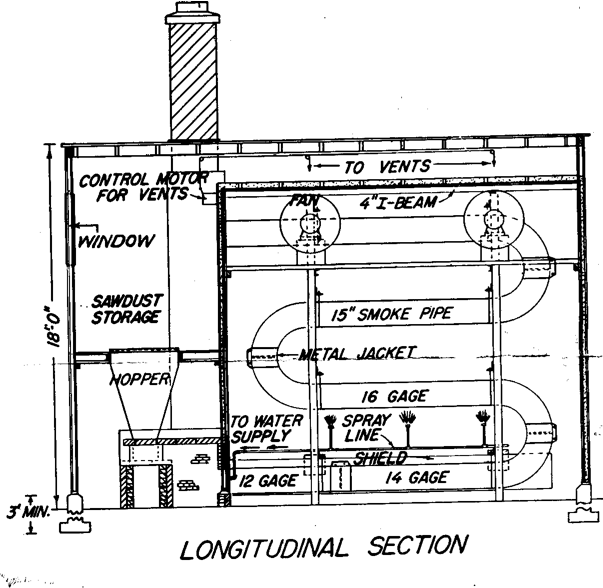

The amount of water extracted from green lumber using supercritical co2

|

Using Supercritical CO2 to Kiln Dry Wood

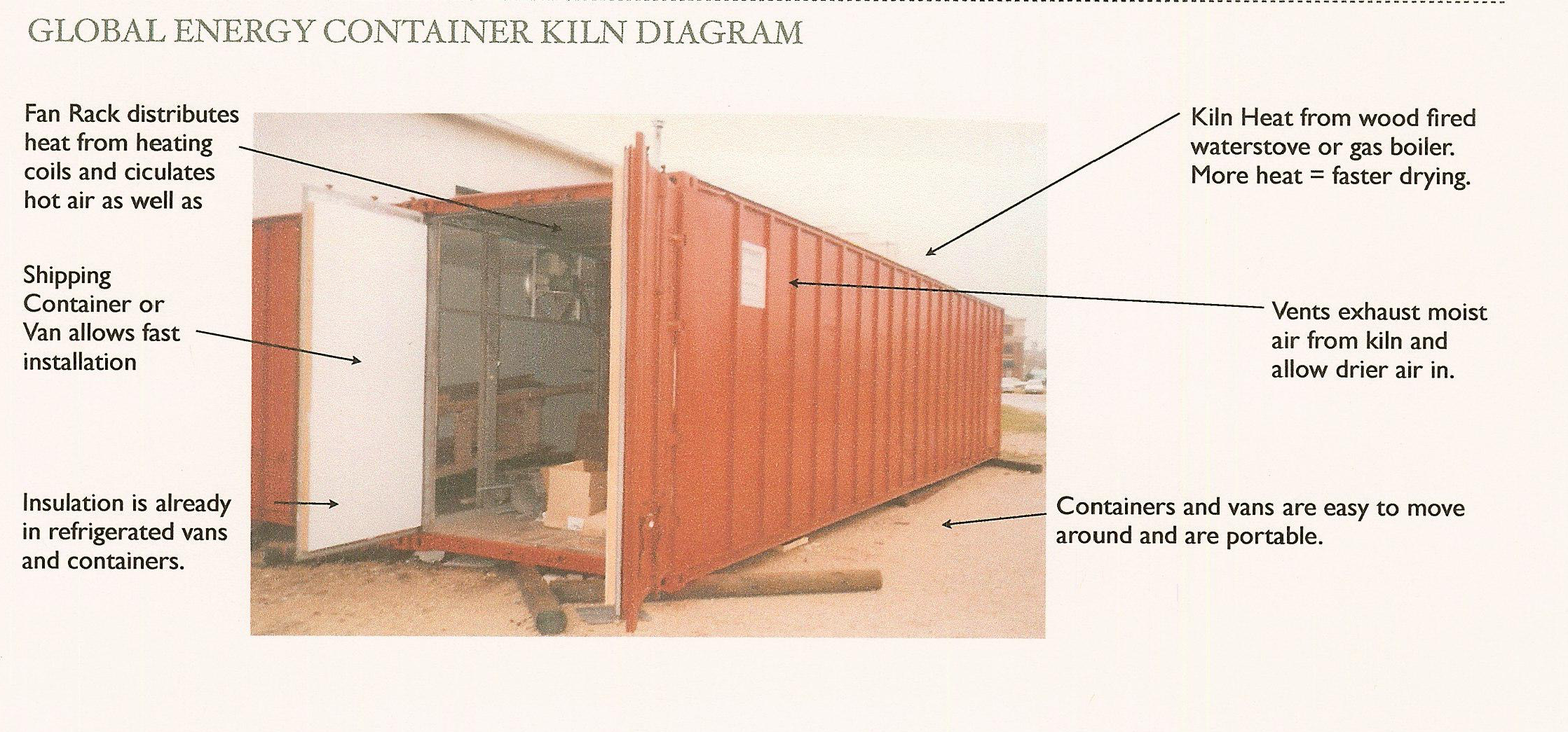

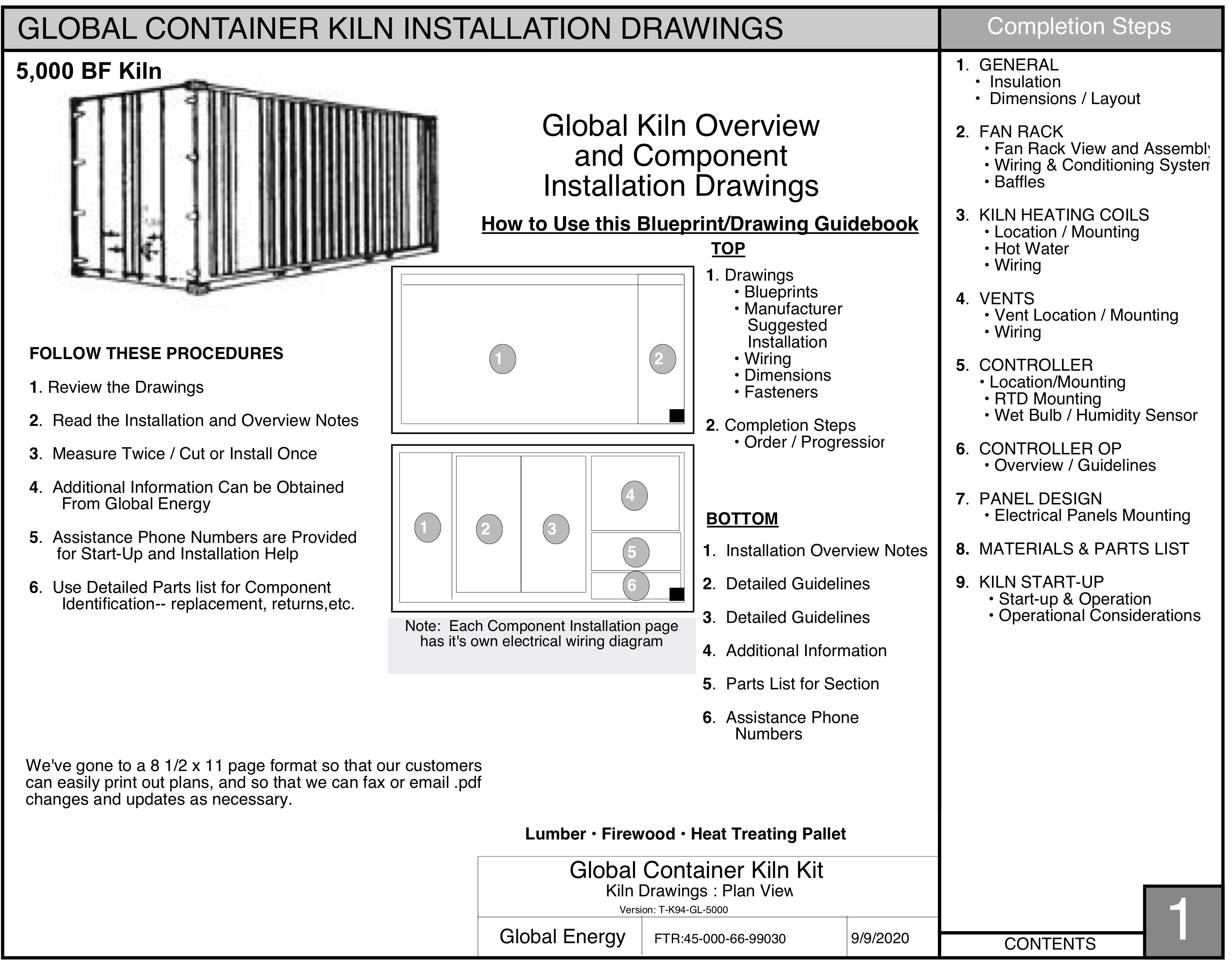

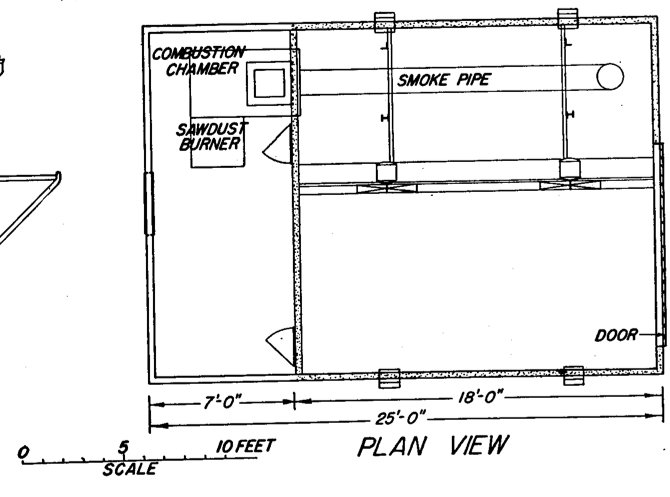

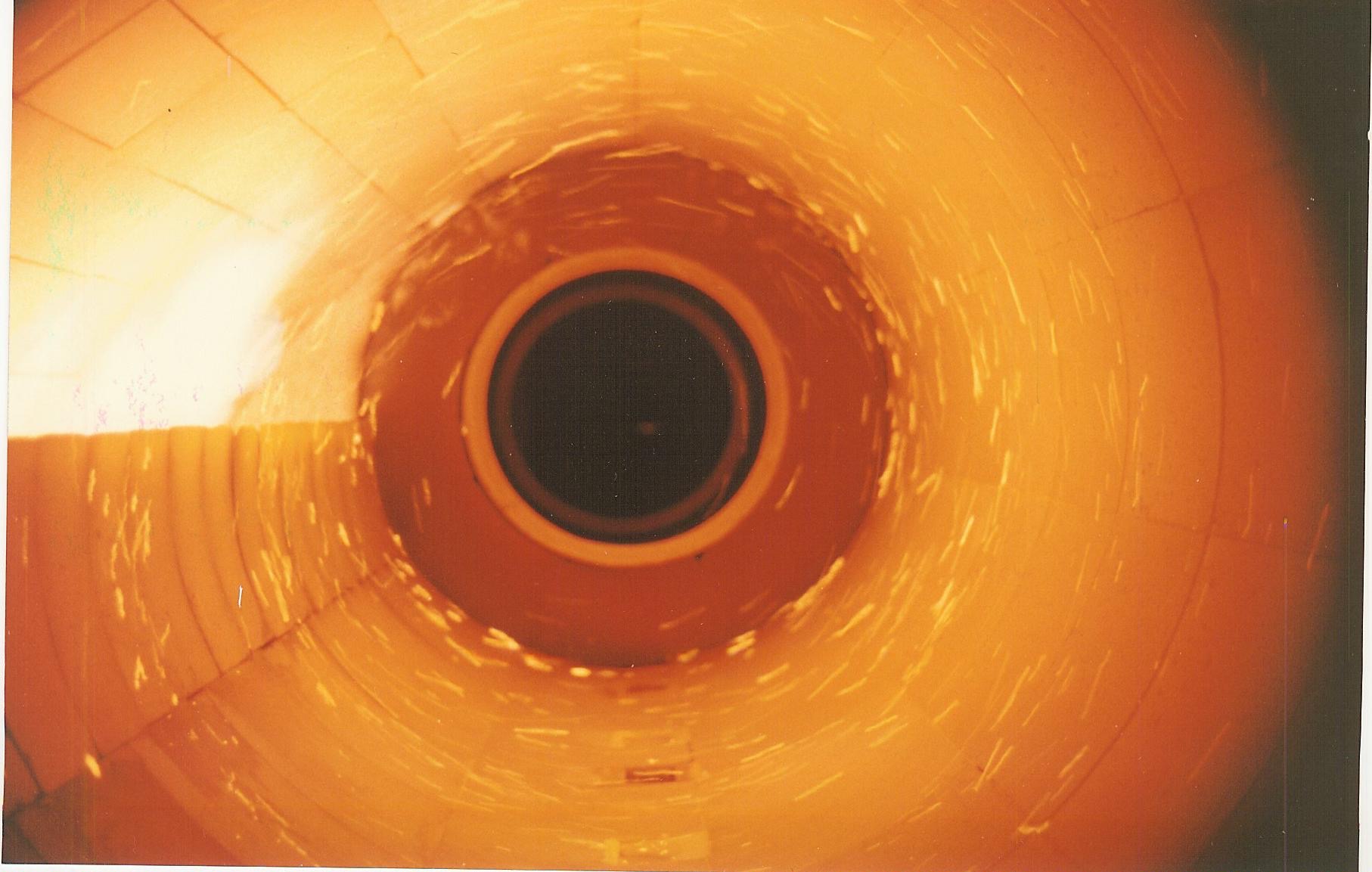

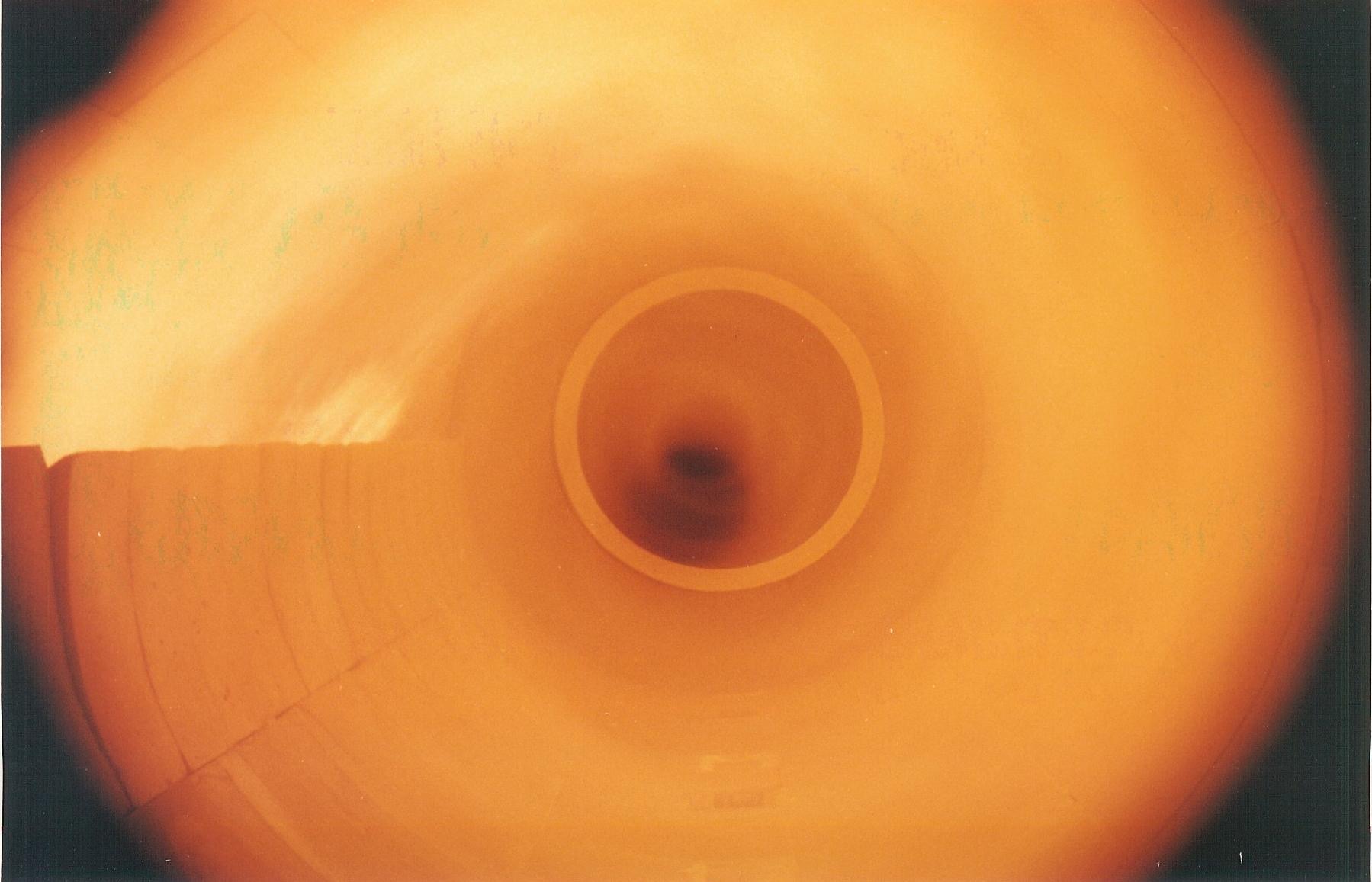

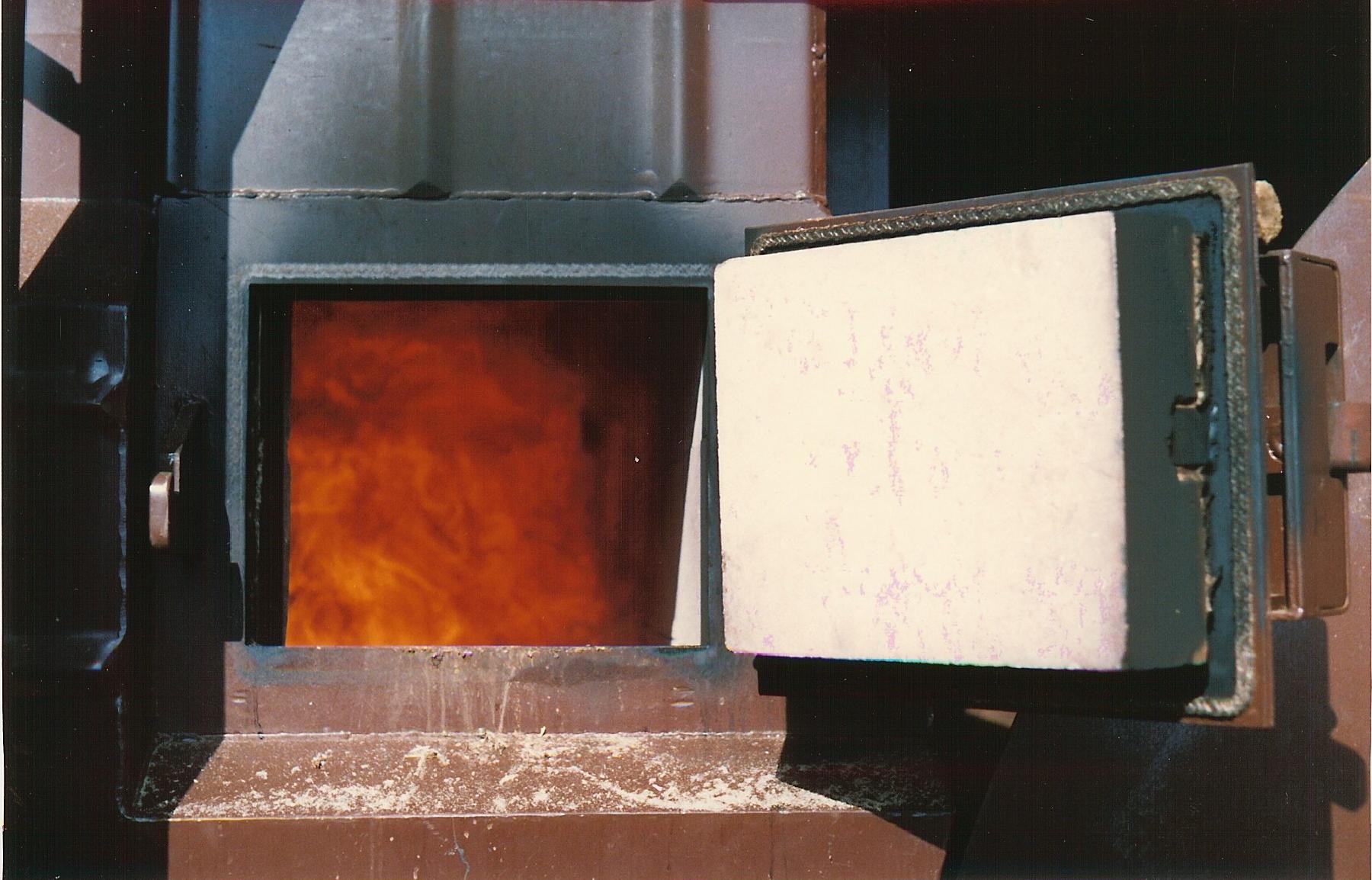

Conventional kiln drying of wood operates by the evaporation of water at elevated temperature. In the initial stage of drying, mobile water in the wood cell lumen evaporates. More slowly, water bound in the wood cell walls evaporates, requiring the breaking of hydrogen bonds between water molecules and cellulose and hemicellulose polymers in the cell wall. An alternative for wood kiln drying is a patented process for green wood dewatering through the molecular interaction of supercritical carbon dioxide with water of wood cell sap. When the system pressure is reduced to below the critical point, phase change from supercritical fluid to gas occurs with a consequent large change in CO2 volume. This results in the efficient, rapid, mechanical expulsion of liquid sap from wood. A potential advantage of applying the green wood dewatering process described above to produce wood material with moisture content at the fibre saturation point and with no resulting distortion, shrinkage, or discolouration is to use the dry wood output from this process as either a finished product in itself (as in the example of eucalypt wood), or as an intermediate towards wood modification or biocide treatment where, as for the triazoles, the modifying agent or biocide is soluble in supercritical carbon dioxide.The ability to carry out two key steps in the manufacture of dry, durable wood materials and products at a single site, in one factory where the equipment and machinery could be used for both drying and molecular-modifying steps, would potentially eliminate the multiple handling of wood at intermediate conventional processing steps.Trimethyl borate and some boratranes (tricyclic borate esters) are also soluble in supercritical carbon dioxide, making these potential compounds for the modification of dewatered wood using supercritical carbon dioxide as the biocide delivery solvent for the manufacture of biologically durable, quality wood products.Dewatering green sapwood derived from plantation-grown radiata pine and several other softwood and hardwood timber species, using carbon dioxide cycled between the supercritical fluid and gas phase, has proven to be an efficient process for rapidly reducing wood moisture content from as much as 200 percent (based on dry weight) to 40 percent (or below, depending on the anatomical structure of the wood). Dewatering has the added benefit of zero volatile emission compared to kiln drying, with all of the sap chemicals being captured in the exudate, which in turn provides a source of numerous chemicals with potential high value to be obtained from them. While the dewatering process has merit for producing dry timber as an industrial product per se, a significant benefit for wood product manufacture may be the ability to sequentially dewater green wood and then undertake wood material modification. For example, biocide molecules dissolved in supercritical carbon dioxide could be introduced in situ, to impart wood product bio-durability without the need to physically handle the wood material.

Kiln Drying Lumber Using Supercritical CO2 (pdf)Email: Supercritical CO2 Kiln Drying Lumber

|