PDF Publication Title:

Text from PDF Page: 008

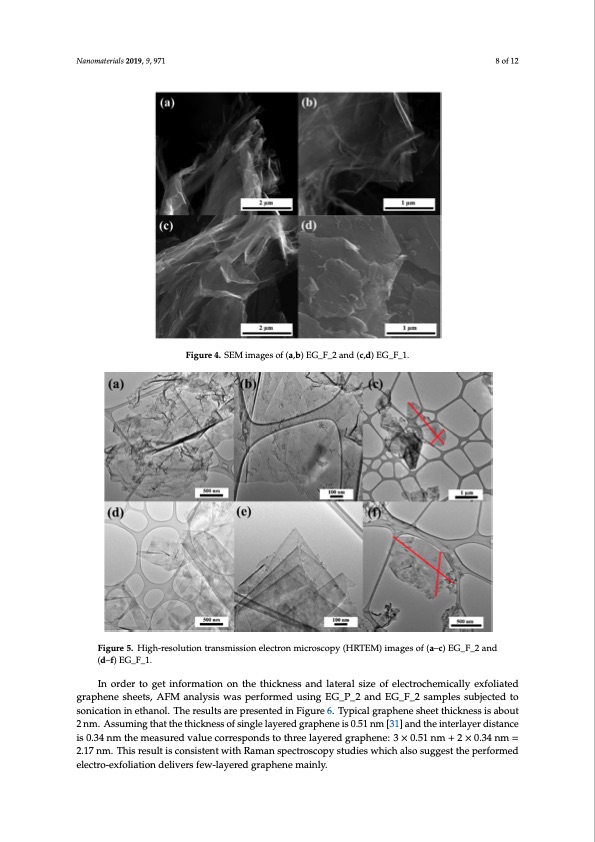

Nanomaterials 2019, 9, 971 8 of 12 Nanomaterials 2019, 9, x FOR PEER REVIEW 8 of 12 Figure 4. SEM images of (a, b) EG_F_2 and (c, d) EG_F_1. The HRTEM technique allowed the dispersion of graphene sheets and was stabilized with small amount of carbon from PFA. Thin-layer graphene sheets were produced at a high yield with large flake sizes (Figure 5). Few-layered graphene sheets can be seen in Figure 5. Images of the sheet edges are visible in Figures 5b,6d; those in Figure 5d indicate that the sheets are 2–4 or more layers thick. The HRTEM images allow to evaluate the size of electrochemically exfoliated graphene sheets as Figure 4. SEM images of (a, b) EG_F_2 and (c, d) EG_F_1. 0.7−4 μm. Figure 4. SEM images of (a,b) EG_F_2 and (c,d) EG_F_1. The HRTEM technique allowed the dispersion of graphene sheets and was stabilized with small amount of carbon from PFA. Thin-layer graphene sheets were produced at a high yield with large flake sizes (Figure 5). Few-layered graphene sheets can be seen in Figure 5. Images of the sheet edges are visible in Figures 5b,6d; those in Figure 5d indicate that the sheets are 2–4 or more layers thick. The HRTEM images allow to evaluate the size of electrochemically exfoliated graphene sheets as 0.7−4 μm. Figure 5. High-resolution transmission electron microscopy (HRTEM) images of (a–c) EG_F_2 and Figure 5. High-resolution transmission electron microscopy (HRTEM) images of (a–c) EG_F_2 and (d–f) EG_F_1. (d–f) EG_F_1. InordIenrotordgeerttionfgoertmiantfiornmoantiotnheotnhitchkenethssickandesslaatenrdallasitzeeraolfsiezlecotrfoeclheecmtroicahlelymeicxaflolyliaetexdfoliated graphegnraepsheneets,shAeFetMs, aAnFaMlysaisnawlyasispwerafosrpmeerdforumsiendg uEsGin_gP_E2Ga_nPd_2EGan_dF_E2Gs_aFm_p2lessamsupblejesctseudbjteocted to sonication in ethanol. The results are presented in Figure 6. Typical graphene sheet thickness is about 2 nm. Assuming that the thickness of single layered graphene is 0.51 nm [31] and the interlayer distance Figure 5. High-resolution transmission electron microscopy (HRTEM) images of (a–c) EG_F_2 and is 0.34 nm the measured value corresponds to three layered graphene: 3 × 0.51 nm + 2 × 0.34 nm = (d–f) EG_F_1. 2.17 nm. This result is consistent with Raman spectroscopy studies which also suggest the performed electro-exfoliation delivers few-layered graphene mainly. In order to get information on the thickness and lateral size of electrochemically exfoliated graphene sheets, AFM analysis was performed using EG_P_2 and EG_F_2 samples subjected toPDF Image | Electro-Exfoliation of Graphite to Graphene

PDF Search Title:

Electro-Exfoliation of Graphite to GrapheneOriginal File Name Searched:

graphene-aqueous-salt-al.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |