PDF Publication Title:

Text from PDF Page: 005

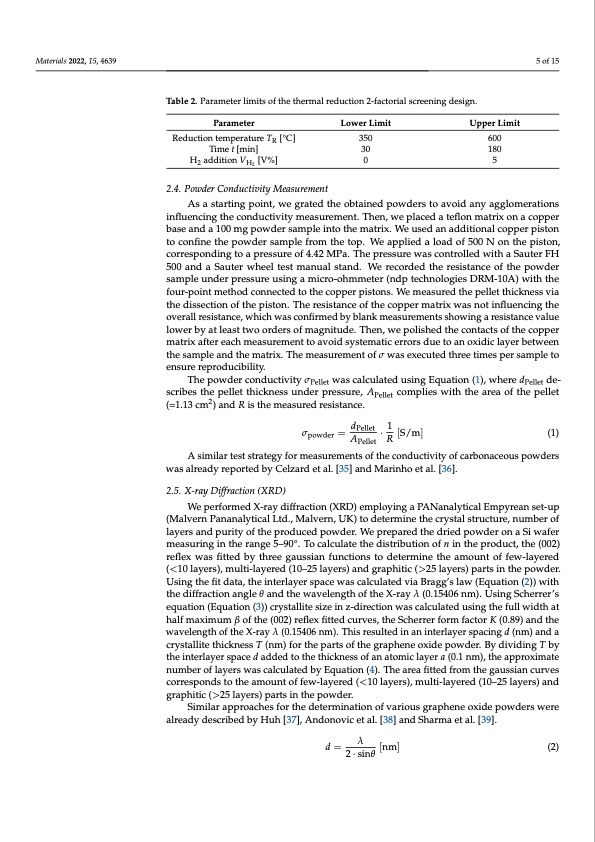

Materials 2022, 15, 4639 5 of 15 Table 2. Parameter limits of the thermal reduction 2-factorial screening design. Parameter Reduction temperature TR [°C] Time t [min] H2 addition VH2 [V%] 2.4. Powder Conductivity Measurement Lower Limit 350 30 0 Upper Limit 600 180 5 As a starting point, we grated the obtained powders to avoid any agglomerations influencing the conductivity measurement. Then, we placed a teflon matrix on a copper base and a 100 mg powder sample into the matrix. We used an additional copper piston to confine the powder sample from the top. We applied a load of 500 N on the piston, corresponding to a pressure of 4.42 MPa. The pressure was controlled with a Sauter FH 500 and a Sauter wheel test manual stand. We recorded the resistance of the powder sample under pressure using a micro-ohmmeter (ndp technologies DRM-10A) with the four-point method connected to the copper pistons. We measured the pellet thickness via the dissection of the piston. The resistance of the copper matrix was not influencing the overall resistance, which was confirmed by blank measurements showing a resistance value lower by at least two orders of magnitude. Then, we polished the contacts of the copper matrix after each measurement to avoid systematic errors due to an oxidic layer between the sample and the matrix. The measurement of σ was executed three times per sample to ensure reproducibility. The powder conductivity σPellet was calculated using Equation (1), where dPellet de- scribes the pellet thickness under pressure, APellet complies with the area of the pellet (=1.13 cm2) and R is the measured resistance. σpowder = dPellet · 1 [S/m] (1) APellet R A similar test strategy for measurements of the conductivity of carbonaceous powders was already reported by Celzard et al. [35] and Marinho et al. [36]. 2.5. X-ray Diffraction (XRD) We performed X-ray diffraction (XRD) employing a PANanalytical Empyrean set-up (Malvern Pananalytical Ltd., Malvern, UK) to determine the crystal structure, number of layers and purity of the produced powder. We prepared the dried powder on a Si wafer measuring in the range 5–90°. To calculate the distribution of n in the product, the (002) reflex was fitted by three gaussian functions to determine the amount of few-layered (<10 layers), multi-layered (10–25 layers) and graphitic (>25 layers) parts in the powder. Using the fit data, the interlayer space was calculated via Bragg’s law (Equation (2)) with the diffraction angle θ and the wavelength of the X-ray λ (0.15406 nm). Using Scherrer’s equation (Equation (3)) crystallite size in z-direction was calculated using the full width at half maximum β of the (002) reflex fitted curves, the Scherrer form factor K (0.89) and the wavelength of the X-ray λ (0.15406 nm). This resulted in an interlayer spacing d (nm) and a crystallite thickness T (nm) for the parts of the graphene oxide powder. By dividing T by the interlayer space d added to the thickness of an atomic layer a (0.1 nm), the approximate number of layers was calculated by Equation (4). The area fitted from the gaussian curves corresponds to the amount of few-layered (<10 layers), multi-layered (10–25 layers) and graphitic (>25 layers) parts in the powder. Similar approaches for the determination of various graphene oxide powders were already described by Huh [37], Andonovic et al. [38] and Sharma et al. [39]. d= λ [nm] (2) 2·sinθPDF Image | Electrochemical Production Thermal Reduction Graphene Oxide

PDF Search Title:

Electrochemical Production Thermal Reduction Graphene OxideOriginal File Name Searched:

materials-15-04639.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)