PDF Publication Title:

Text from PDF Page: 010

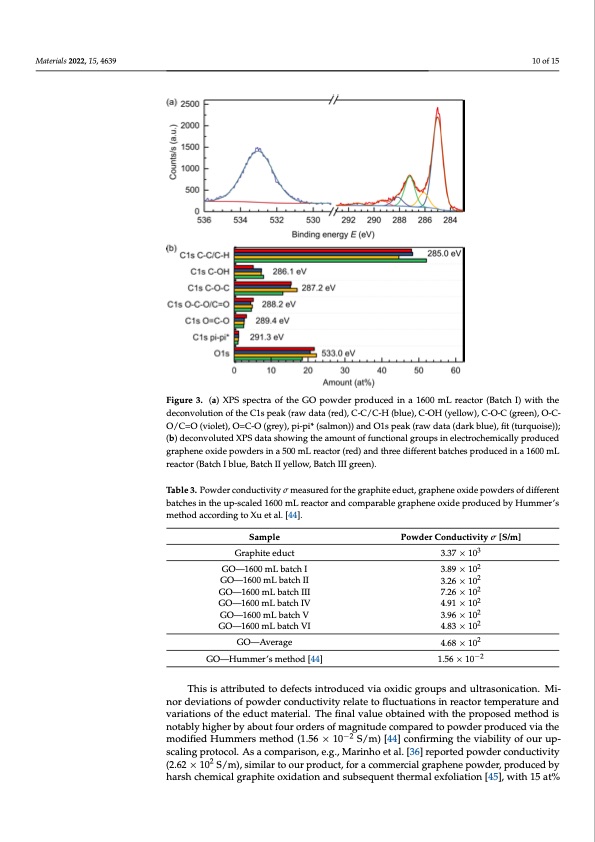

Materials 2022, 15, 4639 10 of 15 Figure 3. (a) XPS spectra of the GO powder produced in a 1600 mL reactor (Batch I) with the deconvolution of the C1s peak (raw data (red), C-C/C-H (blue), C-OH (yellow), C-O-C (green), O-C- O/C=O (violet), O=C-O (grey), pi-pi* (salmon)) and O1s peak (raw data (dark blue), fit (turquoise)); (b) deconvoluted XPS data showing the amount of functional groups in electrochemically produced graphene oxide powders in a 500 mL reactor (red) and three different batches produced in a 1600 mL reactor (Batch I blue, Batch II yellow, Batch III green). Table 3. Powder conductivity σ measured for the graphite educt, graphene oxide powders of different batches in the up-scaled 1600 mL reactor and comparable graphene oxide produced by Hummer’s method according to Xu et al. [44]. Sample Graphite educt GO—1600 mL batch I GO—1600 mL batch II GO—1600 mL batch III GO—1600 mL batch IV GO—1600 mL batch V GO—1600 mL batch VI GO—Average GO—Hummer’s method [44] Powder Conductivity σ [S/m] 3.37 × 103 3.89 × 102 3.26 × 102 7.26 × 102 4.91 × 102 3.96 × 102 4.83 × 102 4.68 × 102 1.56 × 10−2 This is attributed to defects introduced via oxidic groups and ultrasonication. Mi- nor deviations of powder conductivity relate to fluctuations in reactor temperature and variations of the educt material. The final value obtained with the proposed method is notably higher by about four orders of magnitude compared to powder produced via the modified Hummers method (1.56 × 10−2 S/m) [44] confirming the viability of our up- scaling protocol. As a comparison, e.g., Marinho et al. [36] reported powder conductivity (2.62 × 102 S/m), similar to our product, for a commercial graphene powder, produced by harsh chemical graphite oxidation and subsequent thermal exfoliation [45], with 15 at%PDF Image | Electrochemical Production Thermal Reduction Graphene Oxide

PDF Search Title:

Electrochemical Production Thermal Reduction Graphene OxideOriginal File Name Searched:

materials-15-04639.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |