PDF Publication Title:

Text from PDF Page: 012

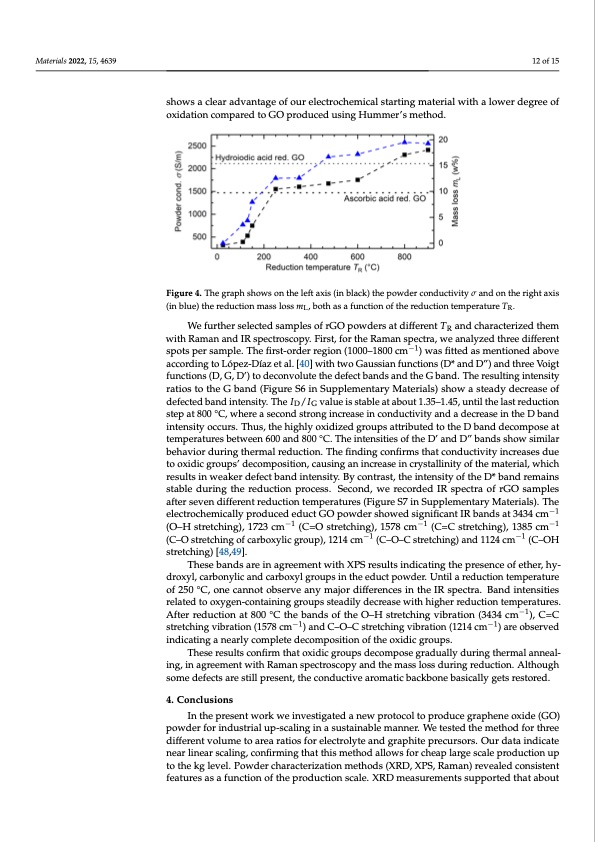

Materials 2022, 15, 4639 12 of 15 shows a clear advantage of our electrochemical starting material with a lower degree of oxidation compared to GO produced using Hummer’s method. Figure 4. The graph shows on the left axis (in black) the powder conductivity σ and on the right axis (in blue) the reduction mass loss mL, both as a function of the reduction temperature TR. We further selected samples of rGO powders at different TR and characterized them with Raman and IR spectroscopy. First, for the Raman spectra, we analyzed three different spots per sample. The first-order region (1000–1800 cm−1) was fitted as mentioned above according to López-Díaz et al. [40] with two Gaussian functions (D* and D”) and three Voigt functions (D, G, D’) to deconvolute the defect bands and the G band. The resulting intensity ratios to the G band (Figure S6 in Supplementary Materials) show a steady decrease of defected band intensity. The ID/IG value is stable at about 1.35–1.45, until the last reduction step at 800 °C, where a second strong increase in conductivity and a decrease in the D band intensity occurs. Thus, the highly oxidized groups attributed to the D band decompose at temperatures between 600 and 800 °C. The intensities of the D’ and D” bands show similar behavior during thermal reduction. The finding confirms that conductivity increases due to oxidic groups’ decomposition, causing an increase in crystallinity of the material, which results in weaker defect band intensity. By contrast, the intensity of the D* band remains stable during the reduction process. Second, we recorded IR spectra of rGO samples after seven different reduction temperatures (Figure S7 in Supplementary Materials). The electrochemically produced educt GO powder showed significant IR bands at 3434 cm−1 (O–H stretching), 1723 cm−1 (C=O stretching), 1578 cm−1 (C=C stretching), 1385 cm−1 (C–O stretching of carboxylic group), 1214 cm−1 (C–O–C stretching) and 1124 cm−1 (C–OH stretching) [48,49]. These bands are in agreement with XPS results indicating the presence of ether, hy- droxyl, carbonylic and carboxyl groups in the educt powder. Until a reduction temperature of 250 °C, one cannot observe any major differences in the IR spectra. Band intensities related to oxygen-containing groups steadily decrease with higher reduction temperatures. After reduction at 800 °C the bands of the O–H stretching vibration (3434 cm−1), C=C stretching vibration (1578 cm−1) and C–O–C stretching vibration (1214 cm−1) are observed indicating a nearly complete decomposition of the oxidic groups. These results confirm that oxidic groups decompose gradually during thermal anneal- ing, in agreement with Raman spectroscopy and the mass loss during reduction. Although some defects are still present, the conductive aromatic backbone basically gets restored. 4. Conclusions In the present work we investigated a new protocol to produce graphene oxide (GO) powder for industrial up-scaling in a sustainable manner. We tested the method for three different volume to area ratios for electrolyte and graphite precursors. Our data indicate near linear scaling, confirming that this method allows for cheap large scale production up to the kg level. Powder characterization methods (XRD, XPS, Raman) revealed consistent features as a function of the production scale. XRD measurements supported that aboutPDF Image | Electrochemical Production Thermal Reduction Graphene Oxide

PDF Search Title:

Electrochemical Production Thermal Reduction Graphene OxideOriginal File Name Searched:

materials-15-04639.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |