PDF Publication Title:

Text from PDF Page: 005

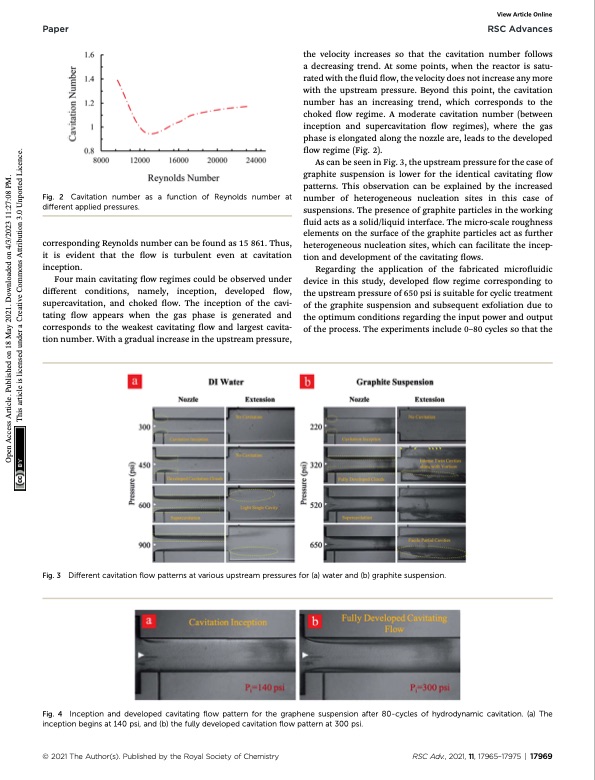

Paper RSC Advances the velocity increases so that the cavitation number follows a decreasing trend. At some points, when the reactor is satu- rated with the uid ow, the velocity does not increase any more with the upstream pressure. Beyond this point, the cavitation number has an increasing trend, which corresponds to the choked ow regime. A moderate cavitation number (between inception and supercavitation ow regimes), where the gas phase is elongated along the nozzle are, leads to the developed ow regime (Fig. 2). As can be seen in Fig. 3, the upstream pressure for the case of graphite suspension is lower for the identical cavitating ow patterns. This observation can be explained by the increased number of heterogeneous nucleation sites in this case of suspensions. The presence of graphite particles in the working uid acts as a solid/liquid interface. The micro-scale roughness elements on the surface of the graphite particles act as further heterogeneous nucleation sites, which can facilitate the incep- tion and development of the cavitating ows. Regarding the application of the fabricated microuidic device in this study, developed ow regime corresponding to the upstream pressure of 650 psi is suitable for cyclic treatment of the graphite suspension and subsequent exfoliation due to the optimum conditions regarding the input power and output of the process. The experiments include 0–80 cycles so that the Fig. 2 Cavitation number as a function of Reynolds number at different applied pressures. corresponding Reynolds number can be found as 15 861. Thus, it is evident that the ow is turbulent even at cavitation inception. Four main cavitating ow regimes could be observed under different conditions, namely, inception, developed ow, supercavitation, and choked ow. The inception of the cavi- tating ow appears when the gas phase is generated and corresponds to the weakest cavitating ow and largest cavita- tion number. With a gradual increase in the upstream pressure, Fig. 3 Different cavitation flow patterns at various upstream pressures for (a) water and (b) graphite suspension. Fig. 4 Inception and developed cavitating flow pattern for the graphene suspension after 80-cycles of hydrodynamic cavitation. (a) The inception begins at 140 psi, and (b) the fully developed cavitation flow pattern at 300 psi. © 2021 The Author(s). Published by the Royal Society of Chemistry RSC Adv., 2021, 11, 17965–17975 | 17969 View Article Online Open Access Article. Published on 18 May 2021. Downloaded on 4/3/2023 11:27:08 PM. This article is licensed under a Creative Commons Attribution 3.0 Unported Licence.PDF Image | graphene exfoliation hydrodynamic cavitation on a chip 2021

PDF Search Title:

graphene exfoliation hydrodynamic cavitation on a chip 2021Original File Name Searched:

d1ra03352b.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)