PDF Publication Title:

Text from PDF Page: 014

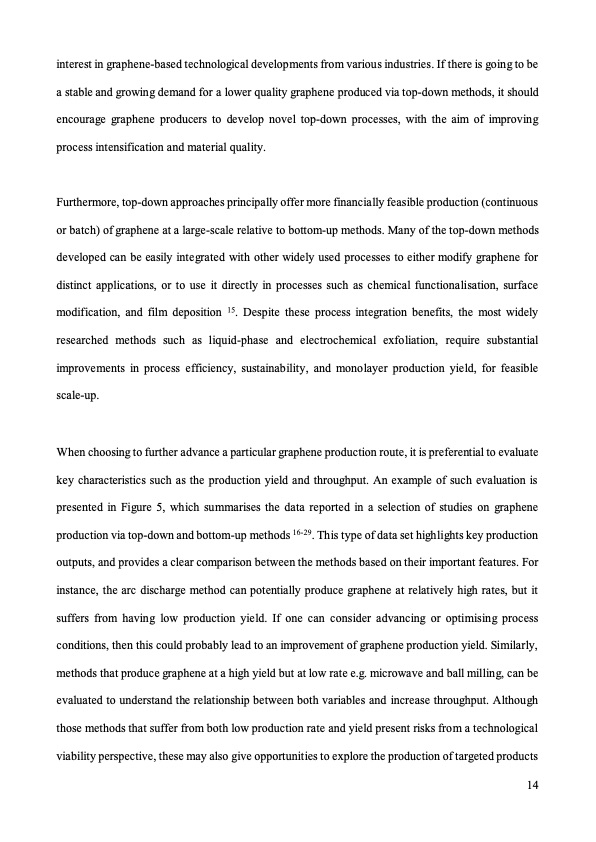

interest in graphene-based technological developments from various industries. If there is going to be a stable and growing demand for a lower quality graphene produced via top-down methods, it should encourage graphene producers to develop novel top-down processes, with the aim of improving process intensification and material quality. Furthermore, top-down approaches principally offer more financially feasible production (continuous or batch) of graphene at a large-scale relative to bottom-up methods. Many of the top-down methods developed can be easily integrated with other widely used processes to either modify graphene for distinct applications, or to use it directly in processes such as chemical functionalisation, surface modification, and film deposition 15. Despite these process integration benefits, the most widely researched methods such as liquid-phase and electrochemical exfoliation, require substantial improvements in process efficiency, sustainability, and monolayer production yield, for feasible scale-up. When choosing to further advance a particular graphene production route, it is preferential to evaluate key characteristics such as the production yield and throughput. An example of such evaluation is presented in Figure 5, which summarises the data reported in a selection of studies on graphene production via top-down and bottom-up methods 16-29. This type of data set highlights key production outputs, and provides a clear comparison between the methods based on their important features. For instance, the arc discharge method can potentially produce graphene at relatively high rates, but it suffers from having low production yield. If one can consider advancing or optimising process conditions, then this could probably lead to an improvement of graphene production yield. Similarly, methods that produce graphene at a high yield but at low rate e.g. microwave and ball milling, can be evaluated to understand the relationship between both variables and increase throughput. Although those methods that suffer from both low production rate and yield present risks from a technological viability perspective, these may also give opportunities to explore the production of targeted products 14PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)