PDF Publication Title:

Text from PDF Page: 024

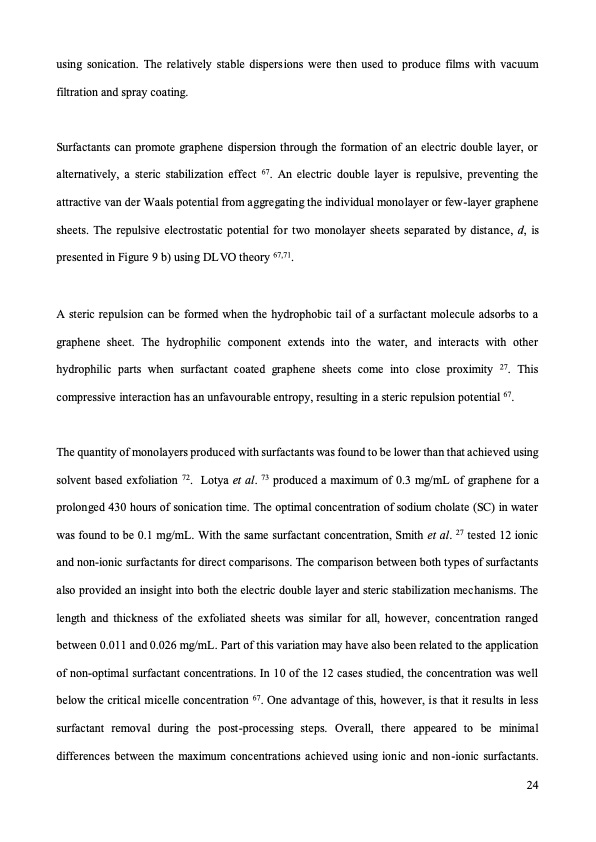

using sonication. The relatively stable dispersions were then used to produce films with vacuum filtration and spray coating. Surfactants can promote graphene dispersion through the formation of an electric double layer, or alternatively, a steric stabilization effect 67. An electric double layer is repulsive, preventing the attractive van der Waals potential from aggregating the individual monolayer or few-layer graphene sheets. The repulsive electrostatic potential for two monolayer sheets separated by distance, d, is presented in Figure 9 b) using DLVO theory 67,71. A steric repulsion can be formed when the hydrophobic tail of a surfactant molecule adsorbs to a graphene sheet. The hydrophilic component extends into the water, and interacts with other hydrophilic parts when surfactant coated graphene sheets come into close proximity 27. This compressive interaction has an unfavourable entropy, resulting in a steric repulsion potential 67. The quantity of monolayers produced with surfactants was found to be lower than that achieved using solvent based exfoliation 72. Lotya et al. 73 produced a maximum of 0.3 mg/mL of graphene for a prolonged 430 hours of sonication time. The optimal concentration of sodium cholate (SC) in water was found to be 0.1 mg/mL. With the same surfactant concentration, Smith et al. 27 tested 12 ionic and non-ionic surfactants for direct comparisons. The comparison between both types of surfactants also provided an insight into both the electric double layer and steric stabilization mechanisms. The length and thickness of the exfoliated sheets was similar for all, however, concentration ranged between 0.011 and 0.026 mg/mL. Part of this variation may have also been related to the application of non-optimal surfactant concentrations. In 10 of the 12 cases studied, the concentration was well below the critical micelle concentration 67. One advantage of this, however, is that it results in less surfactant removal during the post-processing steps. Overall, there appeared to be minimal differences between the maximum concentrations achieved using ionic and non-ionic surfactants. 24PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)