PDF Publication Title:

Text from PDF Page: 029

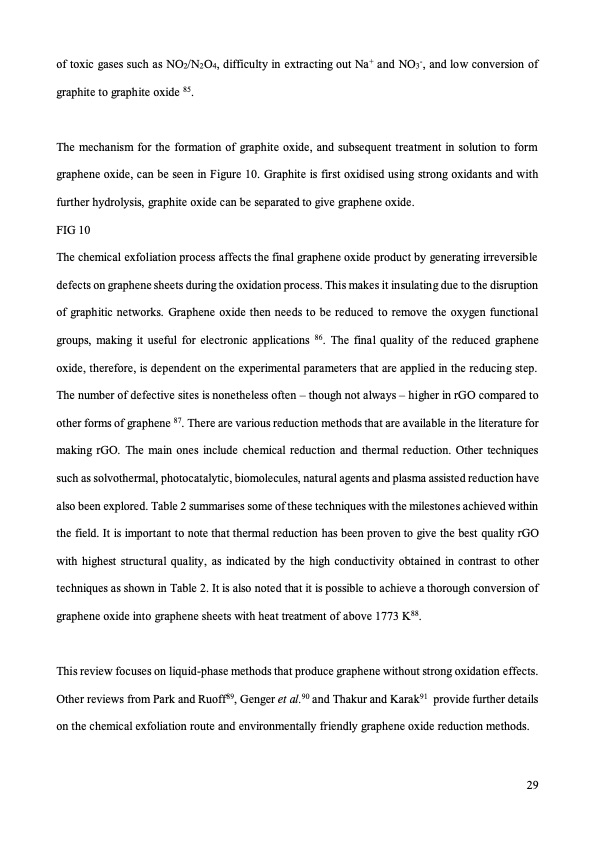

of toxic gases such as NO2/N2O4, difficulty in extracting out Na+ and NO3-, and low conversion of graphite to graphite oxide 85. The mechanism for the formation of graphite oxide, and subsequent treatment in solution to form graphene oxide, can be seen in Figure 10. Graphite is first oxidised using strong oxidants and with further hydrolysis, graphite oxide can be separated to give graphene oxide. FIG 10 The chemical exfoliation process affects the final graphene oxide product by generating irreversible defects on graphene sheets during the oxidation process. This makes it insulating due to the disruption of graphitic networks. Graphene oxide then needs to be reduced to remove the oxygen functional groups, making it useful for electronic applications 86. The final quality of the reduced graphene oxide, therefore, is dependent on the experimental parameters that are applied in the reducing step. The number of defective sites is nonetheless often – though not always – higher in rGO compared to other forms of graphene 87. There are various reduction methods that are available in the literature for making rGO. The main ones include chemical reduction and thermal reduction. Other techniques such as solvothermal, photocatalytic, biomolecules, natural agents and plasma assisted reduction have also been explored. Table 2 summarises some of these techniques with the milestones achieved within the field. It is important to note that thermal reduction has been proven to give the best quality rGO with highest structural quality, as indicated by the high conductivity obtained in contrast to other techniques as shown in Table 2. It is also noted that it is possible to achieve a thorough conversion of graphene oxide into graphene sheets with heat treatment of above 1773 K88. This review focuses on liquid-phase methods that produce graphene without strong oxidation effects. Other reviews from Park and Ruoff89, Genger et al.90 and Thakur and Karak91 provide further details on the chemical exfoliation route and environmentally friendly graphene oxide reduction methods. 29PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)