PDF Publication Title:

Text from PDF Page: 032

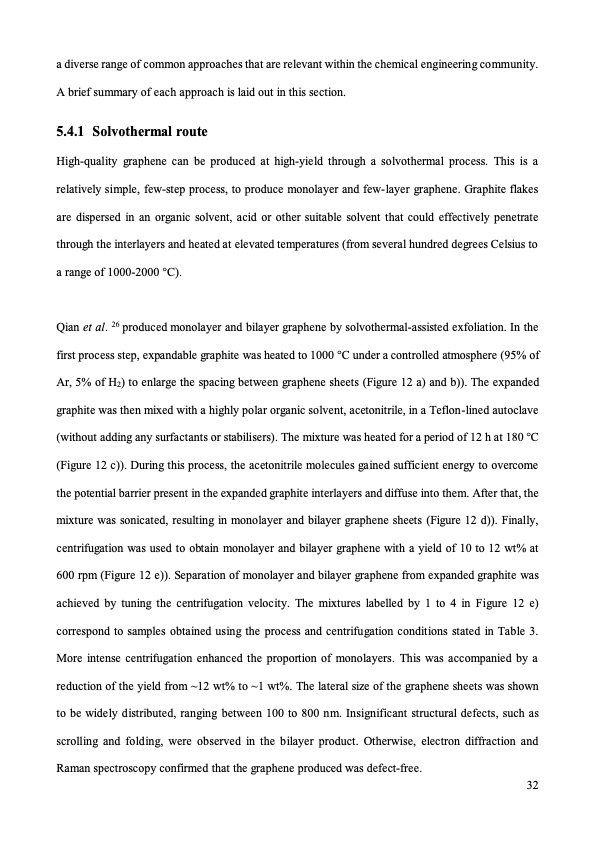

a diverse range of common approaches that are relevant within the chemical engineering community. A brief summary of each approach is laid out in this section. 5.4.1 Solvothermal route High-quality graphene can be produced at high-yield through a solvothermal process. This is a relatively simple, few-step process, to produce monolayer and few-layer graphene. Graphite flakes are dispersed in an organic solvent, acid or other suitable solvent that could effectively penetrate through the interlayers and heated at elevated temperatures (from several hundred degrees Celsius to a range of 1000-2000 °C). Qian et al. 26 produced monolayer and bilayer graphene by solvothermal-assisted exfoliation. In the first process step, expandable graphite was heated to 1000 °C under a controlled atmosphere (95% of Ar, 5% of H2) to enlarge the spacing between graphene sheets (Figure 12 a) and b)). The expanded graphite was then mixed with a highly polar organic solvent, acetonitrile, in a Teflon-lined autoclave (without adding any surfactants or stabilisers). The mixture was heated for a period of 12 h at 180 °C (Figure 12 c)). During this process, the acetonitrile molecules gained sufficient energy to overcome the potential barrier present in the expanded graphite interlayers and diffuse into them. After that, the mixture was sonicated, resulting in monolayer and bilayer graphene sheets (Figure 12 d)). Finally, centrifugation was used to obtain monolayer and bilayer graphene with a yield of 10 to 12 wt% at 600 rpm (Figure 12 e)). Separation of monolayer and bilayer graphene from expanded graphite was achieved by tuning the centrifugation velocity. The mixtures labelled by 1 to 4 in Figure 12 e) correspond to samples obtained using the process and centrifugation conditions stated in Table 3. More intense centrifugation enhanced the proportion of monolayers. This was accompanied by a reduction of the yield from ~12 wt% to ~1 wt%. The lateral size of the graphene sheets was shown to be widely distributed, ranging between 100 to 800 nm. Insignificant structural defects, such as scrolling and folding, were observed in the bilayer product. Otherwise, electron diffraction and Raman spectroscopy confirmed that the graphene produced was defect-free. 32PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |