PDF Publication Title:

Text from PDF Page: 039

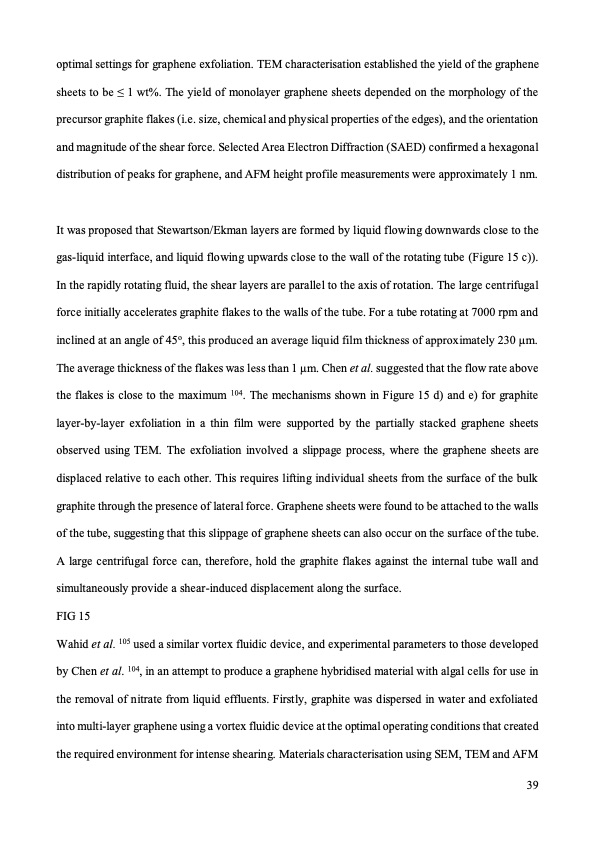

optimal settings for graphene exfoliation. TEM characterisation established the yield of the graphene sheets to be ≤ 1 wt%. The yield of monolayer graphene sheets depended on the morphology of the precursor graphite flakes (i.e. size, chemical and physical properties of the edges), and the orientation and magnitude of the shear force. Selected Area Electron Diffraction (SAED) confirmed a hexagonal distribution of peaks for graphene, and AFM height profile measurements were approximately 1 nm. It was proposed that Stewartson/Ekman layers are formed by liquid flowing downwards close to the gas-liquid interface, and liquid flowing upwards close to the wall of the rotating tube (Figure 15 c)). In the rapidly rotating fluid, the shear layers are parallel to the axis of rotation. The large centrifugal force initially accelerates graphite flakes to the walls of the tube. For a tube rotating at 7000 rpm and inclined at an angle of 45o, this produced an average liquid film thickness of approximately 230 μm. The average thickness of the flakes was less than 1 μm. Chen et al. suggested that the flow rate above the flakes is close to the maximum 104. The mechanisms shown in Figure 15 d) and e) for graphite layer-by-layer exfoliation in a thin film were supported by the partially stacked graphene sheets observed using TEM. The exfoliation involved a slippage process, where the graphene sheets are displaced relative to each other. This requires lifting individual sheets from the surface of the bulk graphite through the presence of lateral force. Graphene sheets were found to be attached to the walls of the tube, suggesting that this slippage of graphene sheets can also occur on the surface of the tube. A large centrifugal force can, therefore, hold the graphite flakes against the internal tube wall and simultaneously provide a shear-induced displacement along the surface. FIG 15 Wahid et al. 105 used a similar vortex fluidic device, and experimental parameters to those developed by Chen et al. 104, in an attempt to produce a graphene hybridised material with algal cells for use in the removal of nitrate from liquid effluents. Firstly, graphite was dispersed in water and exfoliated into multi-layer graphene using a vortex fluidic device at the optimal operating conditions that created the required environment for intense shearing. Materials characterisation using SEM, TEM and AFM 39PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)