PDF Publication Title:

Text from PDF Page: 040

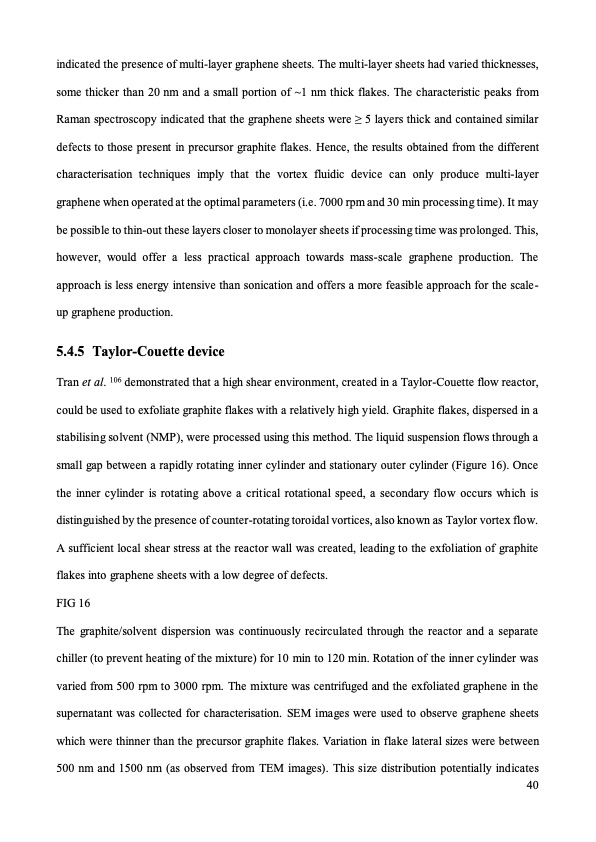

indicated the presence of multi-layer graphene sheets. The multi-layer sheets had varied thicknesses, some thicker than 20 nm and a small portion of ~1 nm thick flakes. The characteristic peaks from Raman spectroscopy indicated that the graphene sheets were ≥ 5 layers thick and contained similar defects to those present in precursor graphite flakes. Hence, the results obtained from the different characterisation techniques imply that the vortex fluidic device can only produce multi-layer graphene when operated at the optimal parameters (i.e. 7000 rpm and 30 min processing time). It may be possible to thin-out these layers closer to monolayer sheets if processing time was prolonged. This, however, would offer a less practical approach towards mass-scale graphene production. The approach is less energy intensive than sonication and offers a more feasible approach for the scale- up graphene production. 5.4.5 Taylor-Couettedevice Tran et al. 106 demonstrated that a high shear environment, created in a Taylor-Couette flow reactor, could be used to exfoliate graphite flakes with a relatively high yield. Graphite flakes, dispersed in a stabilising solvent (NMP), were processed using this method. The liquid suspension flows through a small gap between a rapidly rotating inner cylinder and stationary outer cylinder (Figure 16). Once the inner cylinder is rotating above a critical rotational speed, a secondary flow occurs which is distinguished by the presence of counter-rotating toroidal vortices, also known as Taylor vortex flow. A sufficient local shear stress at the reactor wall was created, leading to the exfoliation of graphite flakes into graphene sheets with a low degree of defects. FIG 16 The graphite/solvent dispersion was continuously recirculated through the reactor and a separate chiller (to prevent heating of the mixture) for 10 min to 120 min. Rotation of the inner cylinder was varied from 500 rpm to 3000 rpm. The mixture was centrifuged and the exfoliated graphene in the supernatant was collected for characterisation. SEM images were used to observe graphene sheets which were thinner than the precursor graphite flakes. Variation in flake lateral sizes were between 500 nm and 1500 nm (as observed from TEM images). This size distribution potentially indicates 40PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |