PDF Publication Title:

Text from PDF Page: 042

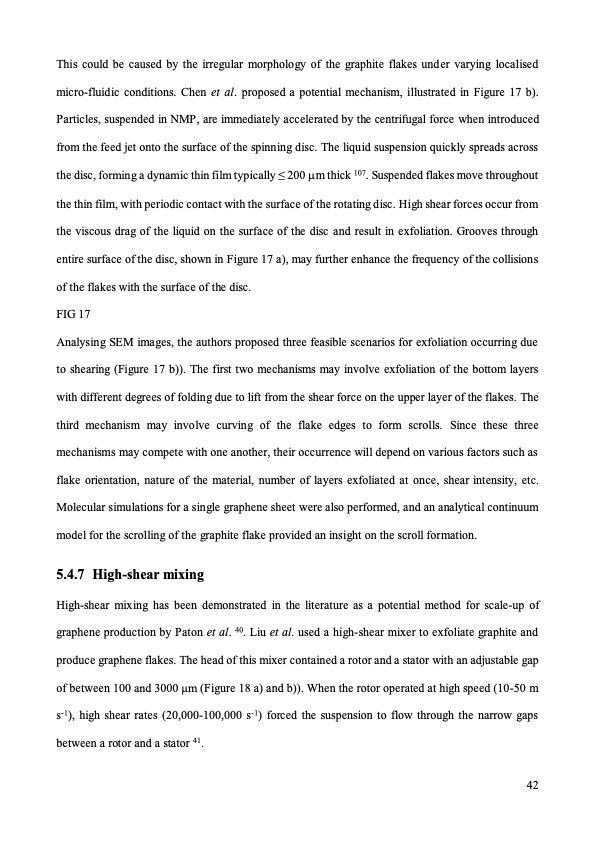

This could be caused by the irregular morphology of the graphite flakes under varying localised micro-fluidic conditions. Chen et al. proposed a potential mechanism, illustrated in Figure 17 b). Particles, suspended in NMP, are immediately accelerated by the centrifugal force when introduced from the feed jet onto the surface of the spinning disc. The liquid suspension quickly spreads across the disc, forming a dynamic thin film typically ≤ 200 m thick 107. Suspended flakes move throughout the thin film, with periodic contact with the surface of the rotating disc. High shear forces occur from the viscous drag of the liquid on the surface of the disc and result in exfoliation. Grooves through entire surface of the disc, shown in Figure 17 a), may further enhance the frequency of the collisions of the flakes with the surface of the disc. FIG 17 Analysing SEM images, the authors proposed three feasible scenarios for exfoliation occurring due to shearing (Figure 17 b)). The first two mechanisms may involve exfoliation of the bottom layers with different degrees of folding due to lift from the shear force on the upper layer of the flakes. The third mechanism may involve curving of the flake edges to form scrolls. Since these three mechanisms may compete with one another, their occurrence will depend on various factors such as flake orientation, nature of the material, number of layers exfoliated at once, shear intensity, etc. Molecular simulations for a single graphene sheet were also performed, and an analytical continuum model for the scrolling of the graphite flake provided an insight on the scroll formation. 5.4.7 High-shearmixing High-shear mixing has been demonstrated in the literature as a potential method for scale-up of graphene production by Paton et al. 40. Liu et al. used a high-shear mixer to exfoliate graphite and produce graphene flakes. The head of this mixer contained a rotor and a stator with an adjustable gap of between 100 and 3000 μm (Figure 18 a) and b)). When the rotor operated at high speed (10-50 m s-1), high shear rates (20,000-100,000 s-1) forced the suspension to flow through the narrow gaps between a rotor and a stator 41. 42PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)