PDF Publication Title:

Text from PDF Page: 045

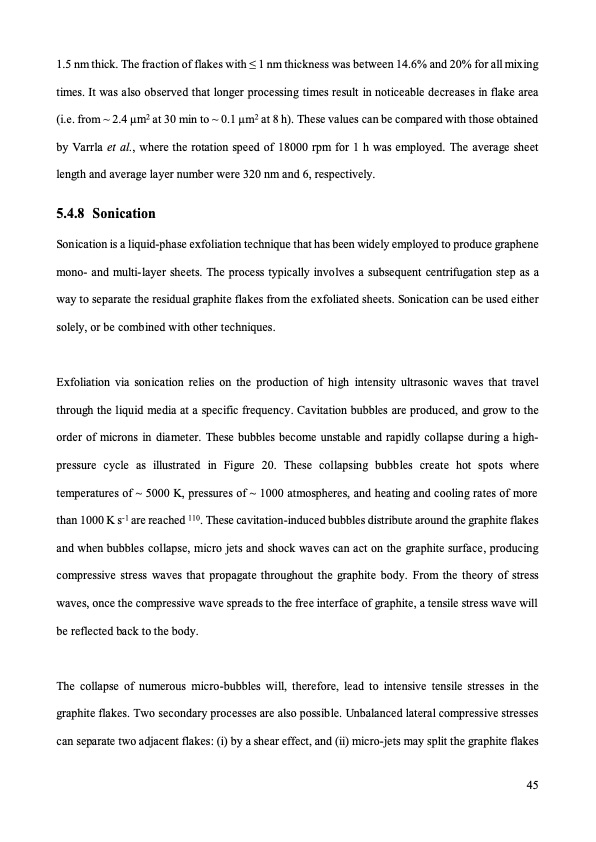

1.5 nm thick. The fraction of flakes with ≤ 1 nm thickness was between 14.6% and 20% for all mixing times. It was also observed that longer processing times result in noticeable decreases in flake area (i.e. from ~ 2.4 μm2 at 30 min to ~ 0.1 μm2 at 8 h). These values can be compared with those obtained by Varrla et al., where the rotation speed of 18000 rpm for 1 h was employed. The average sheet length and average layer number were 320 nm and 6, respectively. 5.4.8 Sonication Sonication is a liquid-phase exfoliation technique that has been widely employed to produce graphene mono- and multi-layer sheets. The process typically involves a subsequent centrifugation step as a way to separate the residual graphite flakes from the exfoliated sheets. Sonication can be used either solely, or be combined with other techniques. Exfoliation via sonication relies on the production of high intensity ultrasonic waves that travel through the liquid media at a specific frequency. Cavitation bubbles are produced, and grow to the order of microns in diameter. These bubbles become unstable and rapidly collapse during a high- pressure cycle as illustrated in Figure 20. These collapsing bubbles create hot spots where temperatures of ~ 5000 K, pressures of ~ 1000 atmospheres, and heating and cooling rates of more than 1000 K s-1 are reached 110. These cavitation-induced bubbles distribute around the graphite flakes and when bubbles collapse, micro jets and shock waves can act on the graphite surface, producing compressive stress waves that propagate throughout the graphite body. From the theory of stress waves, once the compressive wave spreads to the free interface of graphite, a tensile stress wave will be reflected back to the body. The collapse of numerous micro-bubbles will, therefore, lead to intensive tensile stresses in the graphite flakes. Two secondary processes are also possible. Unbalanced lateral compressive stresses can separate two adjacent flakes: (i) by a shear effect, and (ii) micro-jets may split the graphite flakes 45PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |