PDF Publication Title:

Text from PDF Page: 047

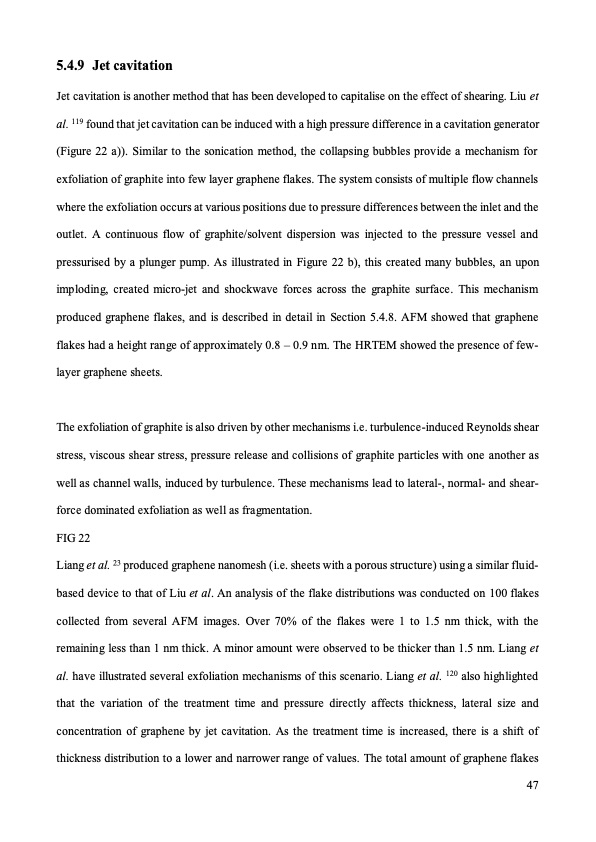

5.4.9 Jetcavitation Jet cavitation is another method that has been developed to capitalise on the effect of shearing. Liu et al. 119 found that jet cavitation can be induced with a high pressure difference in a cavitation generator (Figure 22 a)). Similar to the sonication method, the collapsing bubbles provide a mechanism for exfoliation of graphite into few layer graphene flakes. The system consists of multiple flow channels where the exfoliation occurs at various positions due to pressure differences between the inlet and the outlet. A continuous flow of graphite/solvent dispersion was injected to the pressure vessel and pressurised by a plunger pump. As illustrated in Figure 22 b), this created many bubbles, an upon imploding, created micro-jet and shockwave forces across the graphite surface. This mechanism produced graphene flakes, and is described in detail in Section 5.4.8. AFM showed that graphene flakes had a height range of approximately 0.8 – 0.9 nm. The HRTEM showed the presence of few- layer graphene sheets. The exfoliation of graphite is also driven by other mechanisms i.e. turbulence-induced Reynolds shear stress, viscous shear stress, pressure release and collisions of graphite particles with one another as well as channel walls, induced by turbulence. These mechanisms lead to lateral-, normal- and shear- force dominated exfoliation as well as fragmentation. FIG 22 Liang et al. 23 produced graphene nanomesh (i.e. sheets with a porous structure) using a similar fluid- based device to that of Liu et al. An analysis of the flake distributions was conducted on 100 flakes collected from several AFM images. Over 70% of the flakes were 1 to 1.5 nm thick, with the remaining less than 1 nm thick. A minor amount were observed to be thicker than 1.5 nm. Liang et al. have illustrated several exfoliation mechanisms of this scenario. Liang et al. 120 also highlighted that the variation of the treatment time and pressure directly affects thickness, lateral size and concentration of graphene by jet cavitation. As the treatment time is increased, there is a shift of thickness distribution to a lower and narrower range of values. The total amount of graphene flakes 47PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)