PDF Publication Title:

Text from PDF Page: 095

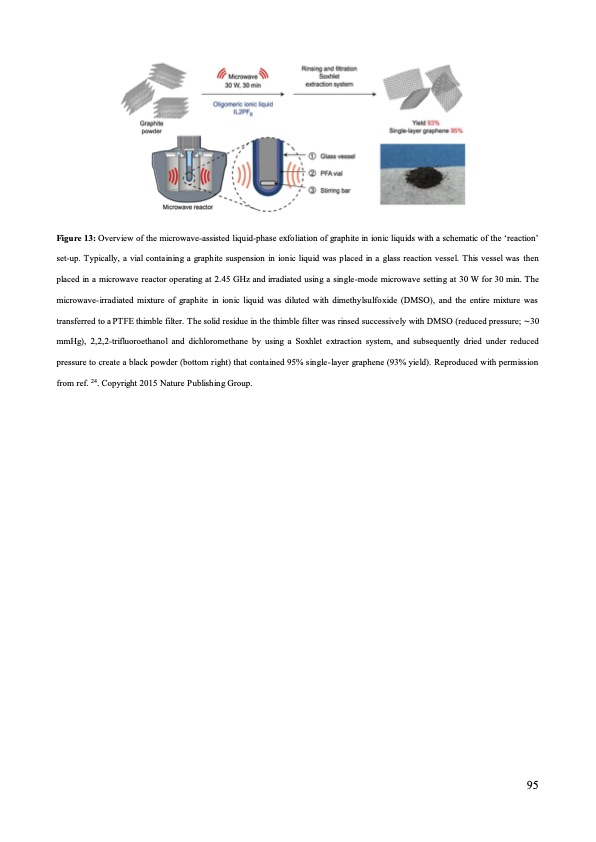

Figure 13: Overview of the microwave-assisted liquid-phase exfoliation of graphite in ionic liquids with a schematic of the ‘reaction’ set-up. Typically, a vial containing a graphite suspension in ionic liquid was placed in a glass reaction vessel. This vessel was then placed in a microwave reactor operating at 2.45 GHz and irradiated using a single-mode microwave setting at 30 W for 30 min. The microwave-irradiated mixture of graphite in ionic liquid was diluted with dimethylsulfoxide (DMSO), and the entire mixture was transferred to a PTFE thimble filter. The solid residue in the thimble filter was rinsed successively with DMSO (reduced pressure; ∼30 mmHg), 2,2,2-trifluoroethanol and dichloromethane by using a Soxhlet extraction system, and subsequently dried under reduced pressure to create a black powder (bottom right) that contained 95% single-layer graphene (93% yield). Reproduced with permission from ref. 24. Copyright 2015 Nature Publishing Group. 95PDF Image | graphene production via nonoxidizing liquid exfoliation

PDF Search Title:

graphene production via nonoxidizing liquid exfoliationOriginal File Name Searched:

Graphene-R2-review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |