PDF Publication Title:

Text from PDF Page: 004

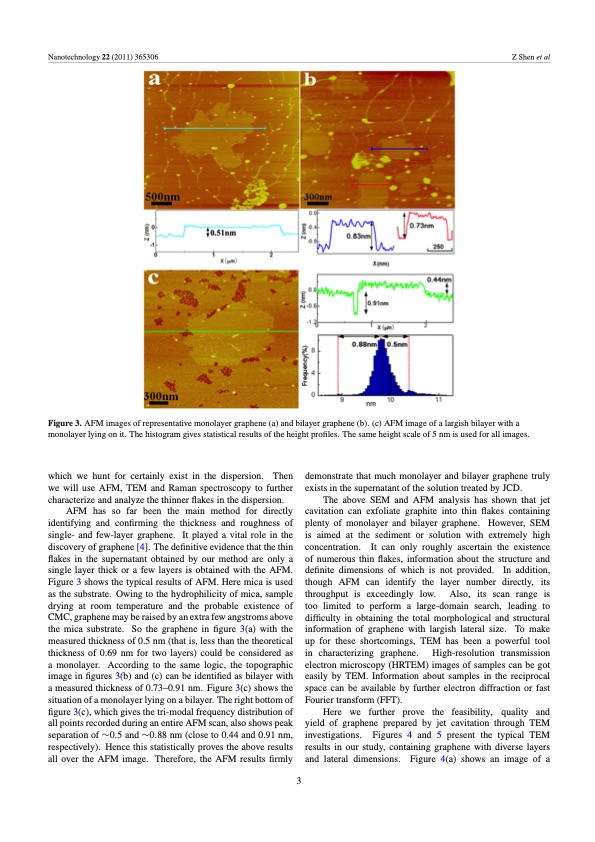

Nanotechnology 22 (2011) 365306 Z Shen et al Figure 3. AFM images of representative monolayer graphene (a) and bilayer graphene (b). (c) AFM image of a largish bilayer with a monolayer lying on it. The histogram gives statistical results of the height profiles. The same height scale of 5 nm is used for all images. which we hunt for certainly exist in the dispersion. Then we will use AFM, TEM and Raman spectroscopy to further characterize and analyze the thinner flakes in the dispersion. AFM has so far been the main method for directly identifying and confirming the thickness and roughness of single- and few-layer graphene. It played a vital role in the discovery of graphene [4]. The definitive evidence that the thin flakes in the supernatant obtained by our method are only a single layer thick or a few layers is obtained with the AFM. Figure 3 shows the typical results of AFM. Here mica is used as the substrate. Owing to the hydrophilicity of mica, sample drying at room temperature and the probable existence of CMC, graphene may be raised by an extra few angstroms above the mica substrate. So the graphene in figure 3(a) with the measured thickness of 0.5 nm (that is, less than the theoretical thickness of 0.69 nm for two layers) could be considered as a monolayer. According to the same logic, the topographic image in figures 3(b) and (c) can be identified as bilayer with a measured thickness of 0.73–0.91 nm. Figure 3(c) shows the situation of a monolayer lying on a bilayer. The right bottom of figure 3(c), which gives the tri-modal frequency distribution of all points recorded during an entire AFM scan, also shows peak separation of ∼0.5 and ∼0.88 nm (close to 0.44 and 0.91 nm, respectively). Hence this statistically proves the above results all over the AFM image. Therefore, the AFM results firmly demonstrate that much monolayer and bilayer graphene truly exists in the supernatant of the solution treated by JCD. The above SEM and AFM analysis has shown that jet cavitation can exfoliate graphite into thin flakes containing plenty of monolayer and bilayer graphene. However, SEM is aimed at the sediment or solution with extremely high concentration. It can only roughly ascertain the existence of numerous thin flakes, information about the structure and definite dimensions of which is not provided. In addition, though AFM can identify the layer number directly, its throughput is exceedingly low. Also, its scan range is too limited to perform a large-domain search, leading to difficulty in obtaining the total morphological and structural information of graphene with largish lateral size. To make up for these shortcomings, TEM has been a powerful tool in characterizing graphene. High-resolution transmission electron microscopy (HRTEM) images of samples can be got easily by TEM. Information about samples in the reciprocal space can be available by further electron diffraction or fast Fourier transform (FFT). Here we further prove the feasibility, quality and yield of graphene prepared by jet cavitation through TEM investigations. Figures 4 and 5 present the typical TEM results in our study, containing graphene with diverse layers and lateral dimensions. Figure 4(a) shows an image of a 3PDF Image | Preparation of graphene by jet cavitation

PDF Search Title:

Preparation of graphene by jet cavitationOriginal File Name Searched:

graphene-by-jet-cavitation.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)