PDF Publication Title:

Text from PDF Page: 006

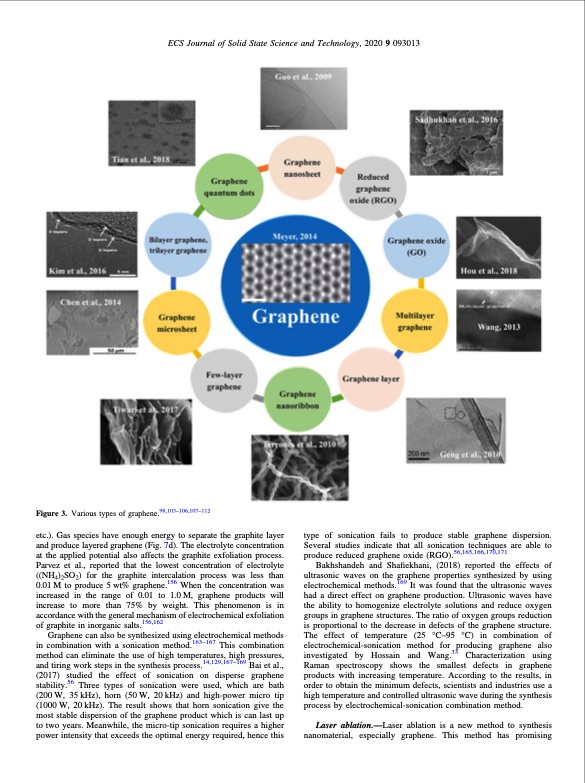

ECS Journal of Solid State Science and Technology, 2020 9 093013 Figure 3. Various types of graphene.98,103–106,107–112 etc.). Gas species have enough energy to separate the graphite layer and produce layered graphene (Fig. 7d). The electrolyte concentration at the applied potential also affects the graphite exfoliation process. Parvez et al., reported that the lowest concentration of electrolyte ((NH4)2SO2) for the graphite intercalation process was less than 0.01 M to produce 5 wt% graphene.156 When the concentration was increased in the range of 0.01 to 1.0M, graphene products will increase to more than 75% by weight. This phenomenon is in accordance with the general mechanism of electrochemical exfoliation of graphite in inorganic salts.156,162 Graphene can also be synthesized using electrochemical methods in combination with a sonication method.163–167 This combination method can eliminate the use of high temperatures, high pressures, and tiring work steps in the synthesis process.14,129,167–169 Bai et al., (2017) studied the effect of sonication on disperse graphene stability.56 Three types of sonication were used, which are bath (200 W, 35 kHz), horn (50 W, 20 kHz) and high-power micro tip (1000 W, 20 kHz). The result shows that horn sonication give the most stable dispersion of the graphene product which is can last up to two years. Meanwhile, the micro-tip sonication requires a higher power intensity that exceeds the optimal energy required, hence this type of sonication fails to produce stable graphene dispersion. Several studies indicate that all sonication techniques are able to produce reduced graphene oxide (RGO).56,165,166,170,171 Bakhshandeh and Shafiekhani, (2018) reported the effects of ultrasonic waves on the graphene properties synthesized by using electrochemical methods.169 It was found that the ultrasonic waves had a direct effect on graphene production. Ultrasonic waves have the ability to homogenize electrolyte solutions and reduce oxygen groups in graphene structures. The ratio of oxygen groups reduction is proportional to the decrease in defects of the graphene structure. The effect of temperature (25 °C–95 °C) in combination of electrochemical-sonication method for producing graphene also investigated by Hossain and Wang.33 Characterization using Raman spectroscopy shows the smallest defects in graphene products with increasing temperature. According to the results, in order to obtain the minimum defects, scientists and industries use a high temperature and controlled ultrasonic wave during the synthesis process by electrochemical-sonication combination method. Laser ablation.—Laser ablation is a new method to synthesis nanomaterial, especially graphene. This method has promisingPDF Image | Progress in Graphene Synthesis

PDF Search Title:

Progress in Graphene SynthesisOriginal File Name Searched:

Progress-in-Graphene-Synthesis-and-its-Application.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)