PDF Publication Title:

Text from PDF Page: 007

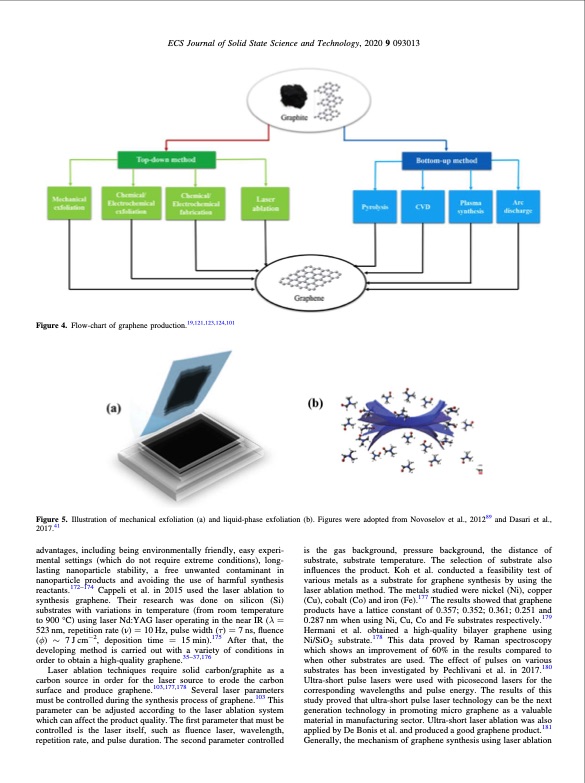

ECS Journal of Solid State Science and Technology, 2020 9 093013 Figure 4. Flow-chart of graphene production.19,121,123,124,101 Figure 5. Illustration of mechanical exfoliation (a) and liquid-phase exfoliation (b). Figures were adopted from Novoselov et al., 201289 and Dasari et al., 2017.41 advantages, including being environmentally friendly, easy experi- mental settings (which do not require extreme conditions), long- lasting nanoparticle stability, a free unwanted contaminant in nanoparticle products and avoiding the use of harmful synthesis reactants.172–174 Cappeli et al. in 2015 used the laser ablation to synthesis graphene. Their research was done on silicon (Si) substrates with variations in temperature (from room temperature to 900 °C) using laser Nd:YAG laser operating in the near IR (λ = 523 nm, repetition rate (ν) = 10 Hz, pulse width (τ) = 7 ns, fluence (φ) ∼ 7 J cm−2, deposition time = 15 min).175 After that, the developing method is carried out with a variety of conditions in order to obtain a high-quality graphene.35–37,176 Laser ablation techniques require solid carbon/graphite as a carbon source in order for the laser source to erode the carbon surface and produce graphene.103,177,178 Several laser parameters must be controlled during the synthesis process of graphene.103 This parameter can be adjusted according to the laser ablation system which can affect the product quality. The first parameter that must be controlled is the laser itself, such as fluence laser, wavelength, repetition rate, and pulse duration. The second parameter controlled is the gas background, pressure background, the distance of substrate, substrate temperature. The selection of substrate also influences the product. Koh et al. conducted a feasibility test of various metals as a substrate for graphene synthesis by using the laser ablation method. The metals studied were nickel (Ni), copper (Cu), cobalt (Co) and iron (Fe).177 The results showed that graphene products have a lattice constant of 0.357; 0.352; 0.361; 0.251 and 0.287 nm when using Ni, Cu, Co and Fe substrates respectively.179 Hermani et al. obtained a high-quality bilayer graphene using Ni/SiO2 substrate.178 This data proved by Raman spectroscopy which shows an improvement of 60% in the results compared to when other substrates are used. The effect of pulses on various substrates has been investigated by Pechlivani et al. in 2017.180 Ultra-short pulse lasers were used with picosecond lasers for the corresponding wavelengths and pulse energy. The results of this study proved that ultra-short pulse laser technology can be the next generation technology in promoting micro graphene as a valuable material in manufacturing sector. Ultra-short laser ablation was also applied by De Bonis et al. and produced a good graphene product.181 Generally, the mechanism of graphene synthesis using laser ablationPDF Image | Progress in Graphene Synthesis

PDF Search Title:

Progress in Graphene SynthesisOriginal File Name Searched:

Progress-in-Graphene-Synthesis-and-its-Application.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)