PDF Publication Title:

Text from PDF Page: 009

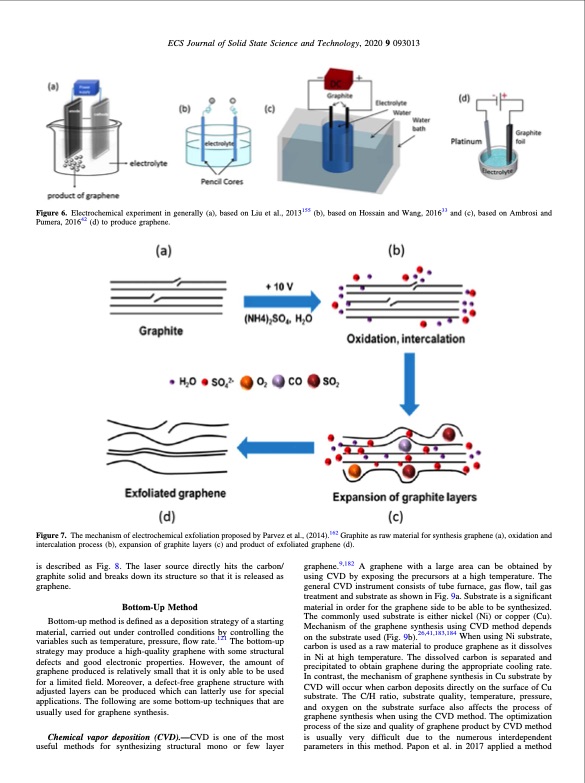

ECS Journal of Solid State Science and Technology, 2020 9 093013 Figure 6. Electrochemical experiment in generally (a), based on Liu et al., 2013155 (b), based on Hossain and Wang, 201633 and (c), based on Ambrosi and Pumera, 201642 (d) to produce graphene. Figure 7. The mechanism of electrochemical exfoliation proposed by Parvez et al., (2014).162 Graphite as raw material for synthesis graphene (a), oxidation and intercalation process (b), expansion of graphite layers (c) and product of exfoliated graphene (d). is described as Fig. 8. The laser source directly hits the carbon/ graphite solid and breaks down its structure so that it is released as graphene. Bottom-Up Method Bottom-up method is defined as a deposition strategy of a starting material, carried out under controlled conditions by controlling the variables such as temperature, pressure, flow rate.121 The bottom-up strategy may produce a high-quality graphene with some structural defects and good electronic properties. However, the amount of graphene produced is relatively small that it is only able to be used for a limited field. Moreover, a defect-free graphene structure with adjusted layers can be produced which can latterly use for special applications. The following are some bottom-up techniques that are usually used for graphene synthesis. Chemical vapor deposition (CVD).—CVD is one of the most useful methods for synthesizing structural mono or few layer graphene.9,182 A graphene with a large area can be obtained by using CVD by exposing the precursors at a high temperature. The general CVD instrument consists of tube furnace, gas flow, tail gas treatment and substrate as shown in Fig. 9a. Substrate is a significant material in order for the graphene side to be able to be synthesized. The commonly used substrate is either nickel (Ni) or copper (Cu). Mechanism of the graphene synthesis using CVD method depends 26,41,183,184 When using Ni substrate, carbon is used as a raw material to produce graphene as it dissolves in Ni at high temperature. The dissolved carbon is separated and precipitated to obtain graphene during the appropriate cooling rate. In contrast, the mechanism of graphene synthesis in Cu substrate by CVD will occur when carbon deposits directly on the surface of Cu substrate. The C/H ratio, substrate quality, temperature, pressure, and oxygen on the substrate surface also affects the process of graphene synthesis when using the CVD method. The optimization process of the size and quality of graphene product by CVD method is usually very difficult due to the numerous interdependent parameters in this method. Papon et al. in 2017 applied a method on the substrate used (Fig. 9b).PDF Image | Progress in Graphene Synthesis

PDF Search Title:

Progress in Graphene SynthesisOriginal File Name Searched:

Progress-in-Graphene-Synthesis-and-its-Application.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |