PDF Publication Title:

Text from PDF Page: 010

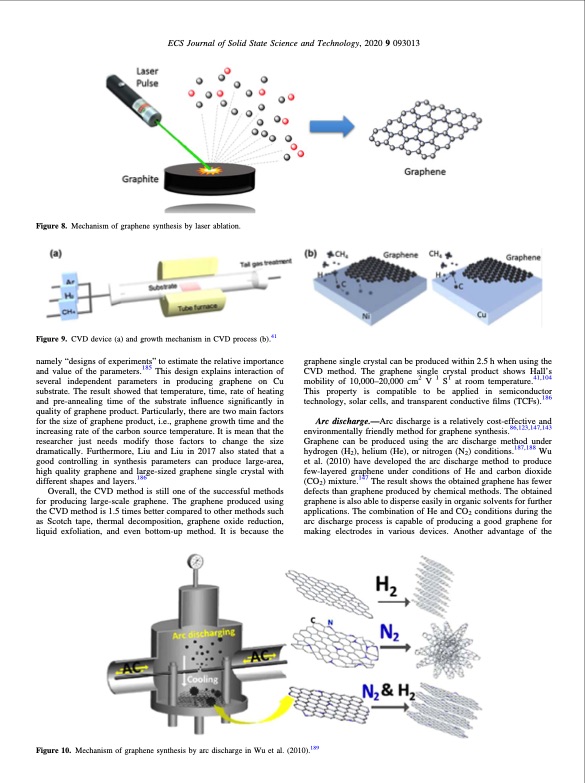

ECS Journal of Solid State Science and Technology, 2020 9 093013 Figure 8. Mechanism of graphene synthesis by laser ablation. Figure 9. CVD device (a) and growth mechanism in CVD process (b).41 namely “designs of experiments” to estimate the relative importance and value of the parameters.185 This design explains interaction of several independent parameters in producing graphene on Cu substrate. The result showed that temperature, time, rate of heating and pre-annealing time of the substrate influence significantly in quality of graphene product. Particularly, there are two main factors for the size of graphene product, i.e., graphene growth time and the increasing rate of the carbon source temperature. It is mean that the researcher just needs modify those factors to change the size dramatically. Furthermore, Liu and Liu in 2017 also stated that a good controlling in synthesis parameters can produce large-area, high quality graphene and large-sized graphene single crystal with different shapes and layers.186 Overall, the CVD method is still one of the successful methods for producing large-scale graphene. The graphene produced using the CVD method is 1.5 times better compared to other methods such as Scotch tape, thermal decomposition, graphene oxide reduction, liquid exfoliation, and even bottom-up method. It is because the graphene single crystal can be produced within 2.5 h when using the CVD method. The graphene single crystal product shows Hall’s mobility of 10,000–20,000 cm2 V 1 S1 at room temperature.41,104 This property is compatible to be applied in semiconductor technology, solar cells, and transparent conductive films (TCFs).186 Arc discharge.—Arc discharge is a relatively cost-effective and environmentally friendly method for graphene synthesis.86,123,147,143 Graphene can be produced using the arc discharge method under hydrogen (H2), helium (He), or nitrogen (N2) conditions.187,188 Wu et al. (2010) have developed the arc discharge method to produce few-layered graphene under conditions of He and carbon dioxide (CO2) mixture.147 The result shows the obtained graphene has fewer defects than graphene produced by chemical methods. The obtained graphene is also able to disperse easily in organic solvents for further applications. The combination of He and CO2 conditions during the arc discharge process is capable of producing a good graphene for making electrodes in various devices. Another advantage of the Figure 10. Mechanism of graphene synthesis by arc discharge in Wu et al. (2010).189PDF Image | Progress in Graphene Synthesis

PDF Search Title:

Progress in Graphene SynthesisOriginal File Name Searched:

Progress-in-Graphene-Synthesis-and-its-Application.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |