PDF Publication Title:

Text from PDF Page: 004

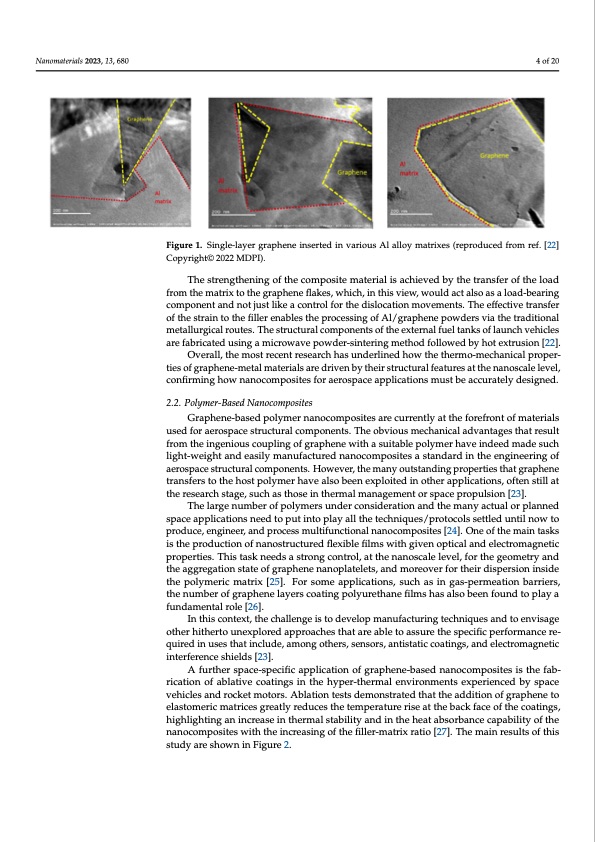

Nanomaterials 2023, 13, 680 been ascribed to the lamellar fine grain structure of the nanofiller. Such features minimise point defects, surface defects, and line dislocations of the host structure. Images of single- 4 of 20 Fiigurre1.. SSiningglele-l-alayyeerrggrraapphheenneeininsseerrteteddininvvaarrioiouussAllaalloloyymaattrrixixeess((rreeprrooduucceeddffrroomrreeff..[[22]] Copyrriightt© 2022 MDPII)).. atomic-thickness graphene embedded in three different grades of aluminium alloy are shown in Figure 1. The strengthening of the composite material is achieved by the transfer of the load The strengthening of the composite material is achieved by the transfer of the load from the matrix to the graphene flakes, which, in this view, would act also as a load-bearing from the matrix to the graphene flakes, which, in this view, would act also as a load-bear- component and not just like a control for the dislocation movements. The effective transfer ing component and not just like a control for the dislocation movements. The effective of the strain to the filler enables the processing of Al/graphene powders via the traditional transfer of the strain to the filler enables the processing of Al/graphene powders via the metallurgical routes. The structural components of the external fuel tanks of launch vehicles traditional metallurgical routes. The structural components of the external fuel tanks of are fabricated using a microwave powder-sintering method followed by hot extrusion [22]. launch vehicles are fabricated using a microwave powder-sintering method followed by Overall, the most recent research has underlined how the thermo-mechanical proper- hot extrusion [22]. ties of graphene-metal materials are driven by their structural features at the nanoscale level, Overall, the most recent research has underlined how the thermo-mechanical prop- confirming how nanocomposites for aerospace applications must be accurately designed. erties of graphene-metal materials are driven by their structural features at the nanoscale level, confirming how nanocomposites for aerospace applications must be accurately de- 2.2. Polymer-Based Nanocomposites signed. Graphene-based polymer nanocomposites are currently at the forefront of materials used for aerospace structural components. The obvious mechanical advantages that result 2.2. Polymer-Based Nanocomposites from the ingenious coupling of graphene with a suitable polymer have indeed made such Graphene-based polymer nanocomposites are currently at the forefront of materials light-weight and easily manufactured nanocomposites a standard in the engineering of used for aerospace structural components. The obvious mechanical advantages that result aerospace structural components. However, the many outstanding properties that graphene from the ingenious coupling of graphene with a suitable polymer have indeed made such transfers to the host polymer have also been exploited in other applications, often still at light-weight and easily manufactured nanocomposites a standard in the engineering of the research stage, such as those in thermal management or space propulsion [23]. aerospace structural components. However, the many outstanding properties that gra- The large number of polymers under consideration and the many actual or planned phene transfers to the host polymer have also been exploited in other applications, often space applications need to put into play all the techniques/protocols settled until now to still at the research stage, such as those in thermal management or space propulsion [23]. produce, engineer, and process multifunctional nanocomposites [24]. One of the main tasks The large number of polymers under consideration and the many actual or planned is the production of nanostructured flexible films with given optical and electromagnetic space applications need to put into play all the techniques/protocols settled until now to properties. This task needs a strong control, at the nanoscale level, for the geometry and produce, engineer, and process multifunctional nanocomposites [24]. One of the main the aggregation state of graphene nanoplatelets, and moreover for their dispersion inside tasks is the production of nanostructured flexible films with given optical and electromag- the polymeric matrix [25]. For some applications, such as in gas-permeation barriers, netic properties. This task needs a strong control, at the nanoscale level, for the geometry the number of graphene layers coating polyurethane films has also been found to play a and the aggregation state of graphene nanoplatelets, and moreover for their dispersion fundamental role [26]. inside the polymeric matrix [25]. For some applications, such as in gas-permeation barri- In this context, the challenge is to develop manufacturing techniques and to envisage ers, the number of graphene layers coating polyurethane films has also been found to play other hitherto unexplored approaches that are able to assure the specific performance re- a fundamental role [26]. quired in uses that include, among others, sensors, antistatic coatings, and electromagnetic In this context, the challenge is to develop manufacturing techniques and to envisage interference shields [23]. other hitherto unexplored approaches that are able to assure the specific performance re- A further space-specific application of graphene-based nanocomposites is the fab- quired in uses that include, among others, sensors, antistatic coatings, and electromag- rication of ablative coatings in the hyper-thermal environments experienced by space nvethicicilnetsearfnedrernocekesht imelodtsor[2s.3]A. blation tests demonstrated that the addition of graphene to elastAomfuertihcemrastpraices-sgprecaitfliycraepdpulicceastitohneotefmgrpaeprhateunre-briasseeadtnthaneobcaocmkpfaocseitoefstihsethcoeaftaibnrgis-, chaitgiohnligohftianbglatnivienccroeatsiengins tihnertmhealhsytapbeirl-ithyearnmdailnetnhveirhoenamt aebnstosrebxapnecreiecnapceadbilbityy sopfatche nanocomposites with the increasing of the filler-matrix ratio [27]. The main results of this study are shown in Figure 2.PDF Image | Role of Graphene in Space Technology

PDF Search Title:

Role of Graphene in Space TechnologyOriginal File Name Searched:

nanomaterials-13-00680-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |