PDF Publication Title:

Text from PDF Page: 006

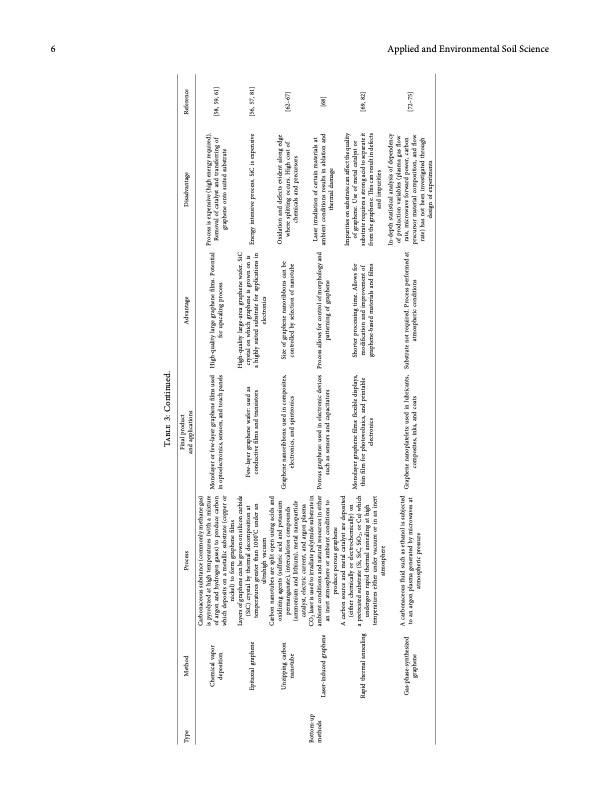

6 Applied and Environmental Soil Science Type Method Chemical vapor deposition Epitaxial graphene Unzipping carbon nanotube Laser-induced graphene Rapid thermal annealing Process Carbonaceous substance (commonly methane gas) is pyrolyzed at high temperatures (with a mixture of argon and hydrogen gases) to produce carbon which deposits on a metallic substrate (copper or nickel) to form graphene flms Layers of graphene can be grown on silicon carbide (SiC) crystal by thermal decomposition at temperatures greater than 1000°C under an ultrahigh vacuum Carbon nanotubes are split open using acids and oxidizing agents (sulfuric acid and potassium permanganate), intercalation compounds (ammonium and lithium), metal nanoparticle catalyst, electric current, and argon plasma CO2 laser is used to irradiate polyimide substrate in ambient conditions and natural resources in either an inert atmosphere or ambient conditions to produce porous graphene A carbon source and metal catalyst are deposited (either chemically or electrochemically) on a pretreated substrate (Si, SiC, SiO2, or Cu) which undergoes rapid thermal annealing at high temperatures either under vacuum or in an inert atmosphere Table 3: Continued. Final product and applications Advantage Disadvantage Reference [58, 59, 61] [56, 57, 81] [62–67] [68] [69, 82] [72–75] Bottom-up methods Porous graphene: used in electronic devices Process allows for control of morphology and such as sensors and capacitators patterning of graphene Monolayer or few-layer graphene flms used High-quality large graphene flms. Potential Process is expensive (high energy required). in optoelectronics, sensors, and touch panels for upscaling process Removal of catalyst and transferring of graphene onto suited substrate Few-layer graphene wafer: used as conductive flms and transistors Graphene nanoribbons: used in composites, electronics, and spintronics High-quality large-area graphene wafer. SiC crystal on which graphene is grown on is a highly suited substrate for applications in electronics Size of graphene nanoribbons can be controlled by selection of nanotube Energy intensive process. SiC is expensive Oxidation and defects evident along edge where splitting occurs. High cost of chemicals and precursors Laser irradiation of certain materials at ambient conditions results in ablation and thermal damage Impurities on substrate can afect the quality of graphene. Use of metal catalyst or substrate requires a strong acid to separate it from the graphene. Tis can result in defects and impurities In-depth statistical analysis of dependency of production variables (plasma gas fow rate, microwave forward power, carbon precursor material composition, and fow rate) has not been investigated through design of experiments Monolayer graphene flms: fexible displays, thin flm for photovoltaics, and printable electronics Shorter processing time. Allows for modifcation and improvement of graphene-based materials and flms Gas-phase-synthesized A carbonaceous fuid such as ethanol is subjected Graphene nanoplatelets: used in lubricants, Substrate not required. Process performed at graphene to an argon plasma generated by microwaves at atmospheric pressure composites, inks, and coats atmospheric conditionsPDF Image | State-of-the-Art Graphene Synthesis Methods

PDF Search Title:

State-of-the-Art Graphene Synthesis MethodsOriginal File Name Searched:

8475504.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)