PDF Publication Title:

Text from PDF Page: 014

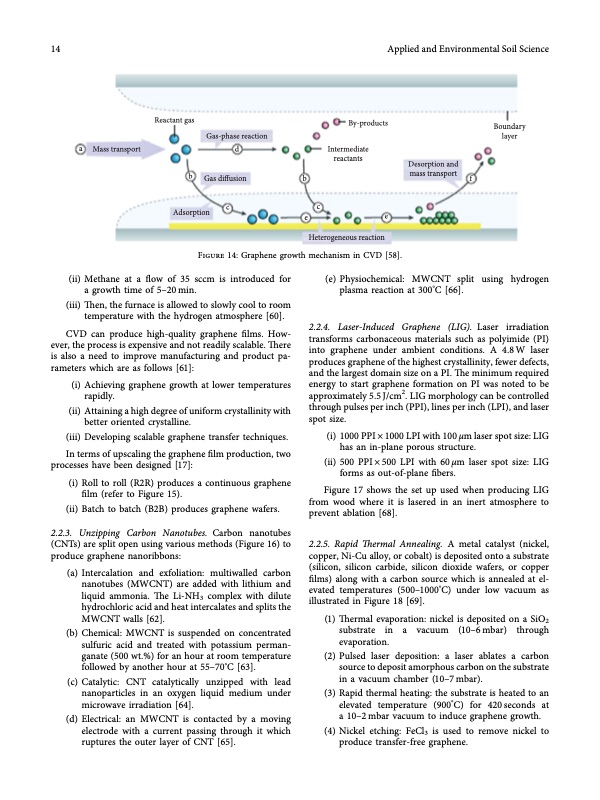

14 Applied and Environmental Soil Science a Mass transport Gas-phase reaction d Gas difusion Reactant gas b Adsorption By-products Intermediate reactants Boundary layer (ii) Methane at a fow of 35 sccm is introduced for a growth time of 5–20 min. (iii) Ten, the furnace is allowed to slowly cool to room temperature with the hydrogen atmosphere [60]. CVD can produce high-quality graphene flms. How- ever, the process is expensive and not readily scalable. Tere is also a need to improve manufacturing and product pa- rameters which are as follows [61]: (i) Achieving graphene growth at lower temperatures rapidly. (ii) Attaining a high degree of uniform crystallinity with better oriented crystalline. (iii) Developing scalable graphene transfer techniques. In terms of upscaling the graphene flm production, two processes have been designed [17]: (i) Roll to roll (R2R) produces a continuous graphene flm (refer to Figure 15). (ii) Batch to batch (B2B) produces graphene wafers. 2.2.3. Unzipping Carbon Nanotubes. Carbon nanotubes (CNTs) are split open using various methods (Figure 16) to produce graphene nanoribbons: (a) Intercalation and exfoliation: multiwalled carbon nanotubes (MWCNT) are added with lithium and liquid ammonia. Te Li-NH3 complex with dilute hydrochloric acid and heat intercalates and splits the MWCNT walls [62]. (b) Chemical: MWCNT is suspended on concentrated sulfuric acid and treated with potassium perman- ganate (500 wt.%) for an hour at room temperature followed by another hour at 55–70°C [63]. (c) Catalytic: CNT catalytically unzipped with lead nanoparticles in an oxygen liquid medium under microwave irradiation [64]. (d) Electrical: an MWCNT is contacted by a moving electrode with a current passing through it which ruptures the outer layer of CNT [65]. (e) Physiochemical: MWCNT split using hydrogen plasma reaction at 300°C [66]. 2.2.4. Laser-Induced Graphene (LIG). Laser irradiation transforms carbonaceous materials such as polyimide (PI) into graphene under ambient conditions. A 4.8W laser produces graphene of the highest crystallinity, fewer defects, and the largest domain size on a PI. Te minimum required energy to start graphene formation on PI was noted to be approximately 5.5 J/cm2. LIG morphology can be controlled through pulses per inch (PPI), lines per inch (LPI), and laser spot size. (i) 1000 PPI × 1000 LPI with 100 μm laser spot size: LIG has an in-plane porous structure. (ii) 500 PPI×500 LPI with 60μm laser spot size: LIG forms as out-of-plane fbers. Figure 17 shows the set up used when producing LIG from wood where it is lasered in an inert atmosphere to prevent ablation [68]. 2.2.5. Rapid Termal Annealing. A metal catalyst (nickel, copper, Ni-Cu alloy, or cobalt) is deposited onto a substrate (silicon, silicon carbide, silicon dioxide wafers, or copper flms) along with a carbon source which is annealed at el- evated temperatures (500–1000°C) under low vacuum as illustrated in Figure 18 [69]. (1) Termal evaporation: nickel is deposited on a SiO2 substrate in a vacuum (10–6 mbar) through evaporation. (2) Pulsed laser deposition: a laser ablates a carbon source to deposit amorphous carbon on the substrate in a vacuum chamber (10–7 mbar). (3) Rapid thermal heating: the substrate is heated to an elevated temperature (900°C) for 420 seconds at a 10–2 mbar vacuum to induce graphene growth. (4) Nickel etching: FeCl3 is used to remove nickel to produce transfer-free graphene. Figure 14: Graphene growth mechanism in CVD [58]. b Desorption and mass transport f cc ee Heterogeneous reactionPDF Image | State-of-the-Art Graphene Synthesis Methods

PDF Search Title:

State-of-the-Art Graphene Synthesis MethodsOriginal File Name Searched:

8475504.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)