PDF Publication Title:

Text from PDF Page: 019

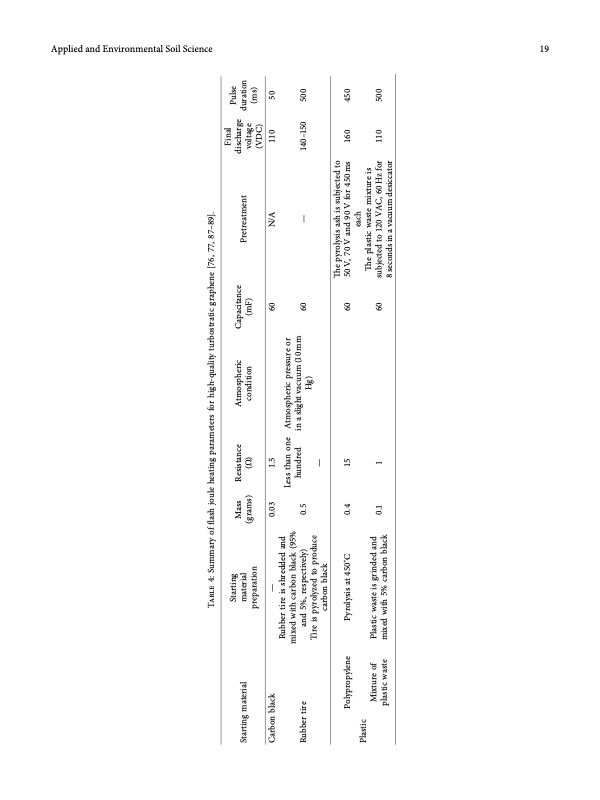

Applied and Environmental Soil Science 19 Starting material Carbon black Rubber tire Starting material preparation Mass Resistance (grams) (Ω) Atmospheric condition Atmospheric pressure or in a slight vacuum (10 mm Hg) Capacitance Pretreatment (mF) 60 N/A 60 — Te pyrolysis ash is subjected to 60 50 V, 70 V and 90 V for 450 ms each Te plastic waste mixture is 60 subjected to 120 VAC, 60 Hz for 8 seconds in a vacuum desiccator Final Pulse discharge duration voltage (ms) (VDC) 110 50 140–150 500 160 450 110 500 Plastic Polypropylene Mixture of plastic waste Table 4: Summary of fash joule heating parameters for high-quality turbostratic graphene [76, 77, 87–89]. — 0.03 1.5 Rubber tire is shredded and Less than one mixed with carbon black (95% hundred and 5%, respectively) 0.5 Tire is pyrolyzed to produce — carbon black Pyrolysis at 450°C 0.4 15 Plastic waste is grinded and 0.1 1 mixed with 5% carbon blackPDF Image | State-of-the-Art Graphene Synthesis Methods

PDF Search Title:

State-of-the-Art Graphene Synthesis MethodsOriginal File Name Searched:

8475504.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)