PDF Publication Title:

Text from PDF Page: 007

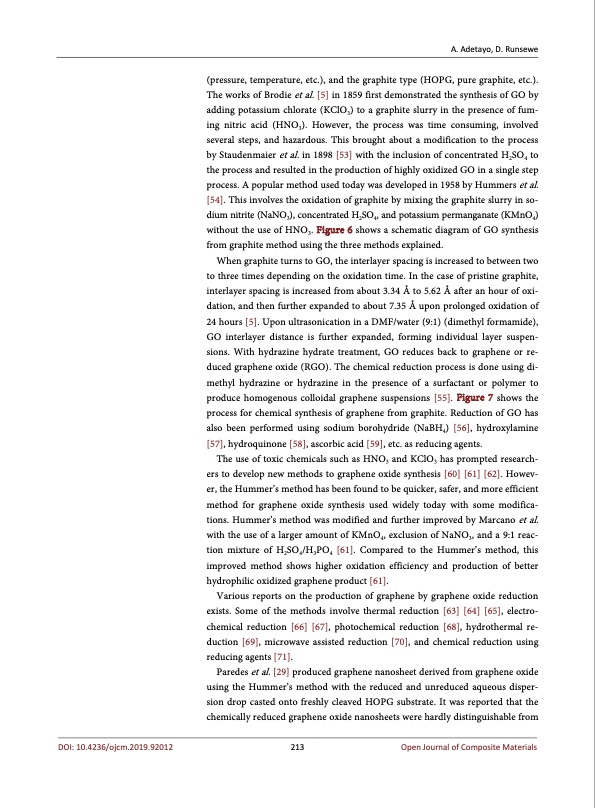

A. Adetayo, D. Runsewe (pressure, temperature, etc.), and the graphite type (HOPG, pure graphite, etc.). The works of Brodie et al. [5] in 1859 first demonstrated the synthesis of GO by adding potassium chlorate (KClO3) to a graphite slurry in the presence of fum- ing nitric acid (HNO3). However, the process was time consuming, involved several steps, and hazardous. This brought about a modification to the process by Staudenmaier et al. in 1898 [53] with the inclusion of concentrated H2SO4 to the process and resulted in the production of highly oxidized GO in a single step process. A popular method used today was developed in 1958 by Hummers et al. [54]. This involves the oxidation of graphite by mixing the graphite slurry in so- dium nitrite (NaNO3), concentrated H2SO4, and potassium permanganate (KMnO4) without the use of HNO3. Figure 6 shows a schematic diagram of GO synthesis from graphite method using the three methods explained. When graphite turns to GO, the interlayer spacing is increased to between two to three times depending on the oxidation time. In the case of pristine graphite, interlayer spacing is increased from about 3.34 Å to 5.62 Å after an hour of oxi- dation, and then further expanded to about 7.35 Å upon prolonged oxidation of 24 hours [5]. Upon ultrasonication in a DMF/water (9:1) (dimethyl formamide), GO interlayer distance is further expanded, forming individual layer suspen- sions. With hydrazine hydrate treatment, GO reduces back to graphene or re- duced graphene oxide (RGO). The chemical reduction process is done using di- methyl hydrazine or hydrazine in the presence of a surfactant or polymer to produce homogenous colloidal graphene suspensions [55]. Figure 7 shows the process for chemical synthesis of graphene from graphite. Reduction of GO has also been performed using sodium borohydride (NaBH4) [56], hydroxylamine [57], hydroquinone [58], ascorbic acid [59], etc. as reducing agents. The use of toxic chemicals such as HNO3 and KClO3 has prompted research- ers to develop new methods to graphene oxide synthesis [60] [61] [62]. Howev- er, the Hummer’s method has been found to be quicker, safer, and more efficient method for graphene oxide synthesis used widely today with some modifica- tions. Hummer’s method was modified and further improved by Marcano et al. with the use of a larger amount of KMnO4, exclusion of NaNO3, and a 9:1 reac- tion mixture of H2SO4/H3PO4 [61]. Compared to the Hummer’s method, this improved method shows higher oxidation efficiency and production of better hydrophilic oxidized graphene product [61]. Various reports on the production of graphene by graphene oxide reduction exists. Some of the methods involve thermal reduction [63] [64] [65], electro- chemical reduction [66] [67], photochemical reduction [68], hydrothermal re- duction [69], microwave assisted reduction [70], and chemical reduction using reducing agents [71]. Paredes et al. [29] produced graphene nanosheet derived from graphene oxide using the Hummer’s method with the reduced and unreduced aqueous disper- sion drop casted onto freshly cleaved HOPG substrate. It was reported that the chemically reduced graphene oxide nanosheets were hardly distinguishable from DOI: 10.4236/ojcm.2019.92012 213 Open Journal of Composite MaterialsPDF Image | Synthesis and Fabrication of Graphene and Graphene Oxide

PDF Search Title:

Synthesis and Fabrication of Graphene and Graphene OxideOriginal File Name Searched:

OJCM-2019042814574897.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)