PDF Publication Title:

Text from PDF Page: 012

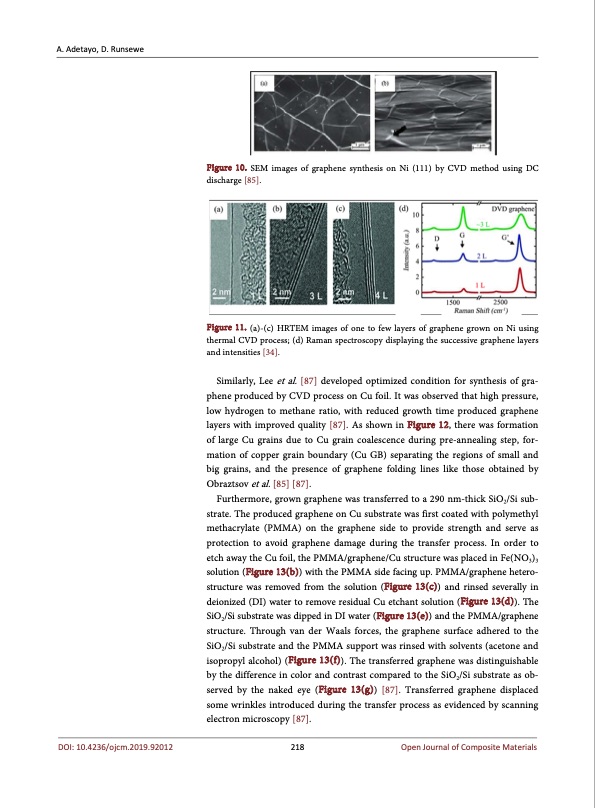

A. Adetayo, D. Runsewe Figure 10. SEM images of graphene synthesis on Ni (111) by CVD method using DC discharge [85]. Figure 11. (a)-(c) HRTEM images of one to few layers of graphene grown on Ni using thermal CVD process; (d) Raman spectroscopy displaying the successive graphene layers and intensities [34]. Similarly, Lee et al. [87] developed optimized condition for synthesis of gra- phene produced by CVD process on Cu foil. It was observed that high pressure, low hydrogen to methane ratio, with reduced growth time produced graphene layers with improved quality [87]. As shown in Figure 12, there was formation of large Cu grains due to Cu grain coalescence during pre-annealing step, for- mation of copper grain boundary (Cu GB) separating the regions of small and big grains, and the presence of graphene folding lines like those obtained by Obraztsov et al. [85] [87]. Furthermore, grown graphene was transferred to a 290 nm-thick SiO2/Si sub- strate. The produced graphene on Cu substrate was first coated with polymethyl methacrylate (PMMA) on the graphene side to provide strength and serve as protection to avoid graphene damage during the transfer process. In order to etch away the Cu foil, the PMMA/graphene/Cu structure was placed in Fe(NO3)3 solution (Figure 13(b)) with the PMMA side facing up. PMMA/graphene hetero- structure was removed from the solution (Figure 13(c)) and rinsed severally in deionized (DI) water to remove residual Cu etchant solution (Figure 13(d)). The SiO2/Si substrate was dipped in DI water (Figure 13(e)) and the PMMA/graphene structure. Through van der Waals forces, the graphene surface adhered to the SiO2/Si substrate and the PMMA support was rinsed with solvents (acetone and isopropyl alcohol) (Figure 13(f)). The transferred graphene was distinguishable by the difference in color and contrast compared to the SiO2/Si substrate as ob- served by the naked eye (Figure 13(g)) [87]. Transferred graphene displaced some wrinkles introduced during the transfer process as evidenced by scanning electron microscopy [87]. DOI: 10.4236/ojcm.2019.92012 218 Open Journal of Composite MaterialsPDF Image | Synthesis and Fabrication of Graphene and Graphene Oxide

PDF Search Title:

Synthesis and Fabrication of Graphene and Graphene OxideOriginal File Name Searched:

OJCM-2019042814574897.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)