PDF Publication Title:

Text from PDF Page: 023

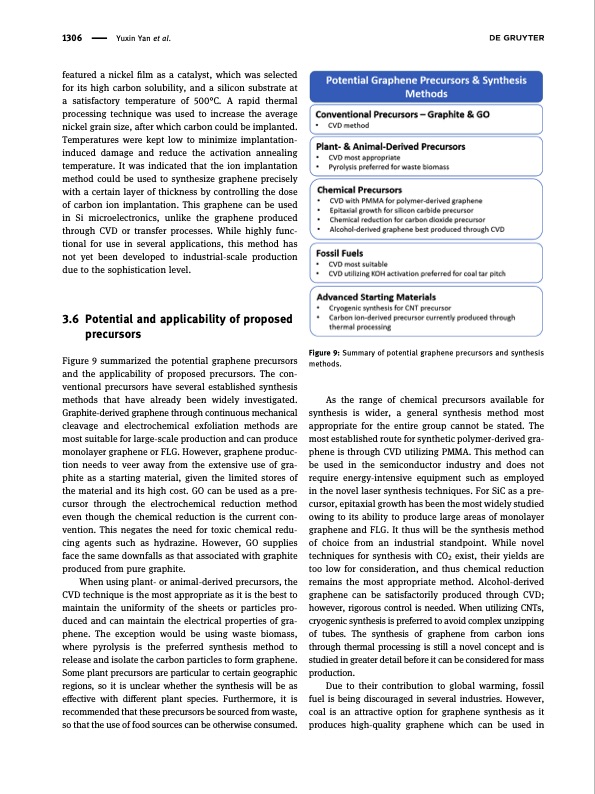

1306 Yuxin Yan et al. featured a nickel film as a catalyst, which was selected for its high carbon solubility, and a silicon substrate at a satisfactory temperature of 500°C. A rapid thermal processing technique was used to increase the average nickel grain size, after which carbon could be implanted. Temperatures were kept low to minimize implantation- induced damage and reduce the activation annealing temperature. It was indicated that the ion implantation method could be used to synthesize graphene precisely with a certain layer of thickness by controlling the dose of carbon ion implantation. This graphene can be used in Si microelectronics, unlike the graphene produced through CVD or transfer processes. While highly func- tional for use in several applications, this method has not yet been developed to industrial-scale production due to the sophistication level. 3.6 Potential and applicability of proposed precursors Figure 9 summarized the potential graphene precursors and the applicability of proposed precursors. The con- ventional precursors have several established synthesis methods that have already been widely investigated. Graphite-derived graphene through continuous mechanical cleavage and electrochemical exfoliation methods are most suitable for large-scale production and can produce monolayer graphene or FLG. However, graphene produc- tion needs to veer away from the extensive use of gra- phite as a starting material, given the limited stores of the material and its high cost. GO can be used as a pre- cursor through the electrochemical reduction method even though the chemical reduction is the current con- vention. This negates the need for toxic chemical redu- cing agents such as hydrazine. However, GO supplies face the same downfalls as that associated with graphite produced from pure graphite. When using plant- or animal-derived precursors, the CVD technique is the most appropriate as it is the best to maintain the uniformity of the sheets or particles pro- duced and can maintain the electrical properties of gra- phene. The exception would be using waste biomass, where pyrolysis is the preferred synthesis method to release and isolate the carbon particles to form graphene. Some plant precursors are particular to certain geographic regions, so it is unclear whether the synthesis will be as effective with different plant species. Furthermore, it is recommended that these precursors be sourced from waste, so that the use of food sources can be otherwise consumed. Figure 9: Summary of potential graphene precursors and synthesis methods. As the range of chemical precursors available for synthesis is wider, a general synthesis method most appropriate for the entire group cannot be stated. The most established route for synthetic polymer-derived gra- phene is through CVD utilizing PMMA. This method can be used in the semiconductor industry and does not require energy-intensive equipment such as employed in the novel laser synthesis techniques. For SiC as a pre- cursor, epitaxial growth has been the most widely studied owing to its ability to produce large areas of monolayer graphene and FLG. It thus will be the synthesis method of choice from an industrial standpoint. While novel techniques for synthesis with CO2 exist, their yields are too low for consideration, and thus chemical reduction remains the most appropriate method. Alcohol-derived graphene can be satisfactorily produced through CVD; however, rigorous control is needed. When utilizing CNTs, cryogenic synthesis is preferred to avoid complex unzipping of tubes. The synthesis of graphene from carbon ions through thermal processing is still a novel concept and is studied in greater detail before it can be considered for mass production. Due to their contribution to global warming, fossil fuel is being discouraged in several industries. However, coal is an attractive option for graphene synthesis as it produces high-quality graphene which can be used inPDF Image | Synthesis of graphene Potential carbon precursors

PDF Search Title:

Synthesis of graphene Potential carbon precursorsOriginal File Name Searched:

10-1515-ntrev-2020-0100.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)