PDF Publication Title:

Text from PDF Page: 004

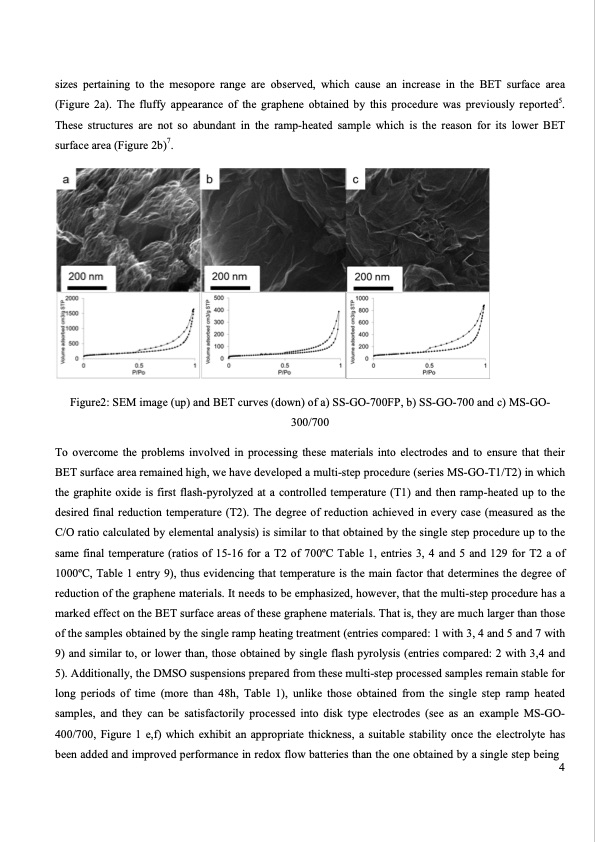

sizes pertaining to the mesopore range are observed, which cause an increase in the BET surface area (Figure 2a). The fluffy appearance of the graphene obtained by this procedure was previously reported5. These structures are not so abundant in the ramp-heated sample which is the reason for its lower BET surface area (Figure 2b)7. Figure2: SEM image (up) and BET curves (down) of a) SS-GO-700FP, b) SS-GO-700 and c) MS-GO- 300/700 To overcome the problems involved in processing these materials into electrodes and to ensure that their BET surface area remained high, we have developed a multi-step procedure (series MS-GO-T1/T2) in which the graphite oxide is first flash-pyrolyzed at a controlled temperature (T1) and then ramp-heated up to the desired final reduction temperature (T2). The degree of reduction achieved in every case (measured as the C/O ratio calculated by elemental analysis) is similar to that obtained by the single step procedure up to the same final temperature (ratios of 15-16 for a T2 of 700oC Table 1, entries 3, 4 and 5 and 129 for T2 a of 1000oC, Table 1 entry 9), thus evidencing that temperature is the main factor that determines the degree of reduction of the graphene materials. It needs to be emphasized, however, that the multi-step procedure has a marked effect on the BET surface areas of these graphene materials. That is, they are much larger than those of the samples obtained by the single ramp heating treatment (entries compared: 1 with 3, 4 and 5 and 7 with 9) and similar to, or lower than, those obtained by single flash pyrolysis (entries compared: 2 with 3,4 and 5). Additionally, the DMSO suspensions prepared from these multi-step processed samples remain stable for long periods of time (more than 48h, Table 1), unlike those obtained from the single step ramp heated samples, and they can be satisfactorily processed into disk type electrodes (see as an example MS-GO- 400/700, Figure 1 e,f) which exhibit an appropriate thickness, a suitable stability once the electrolyte has been added and improved performance in redox flow batteries than the one obtained by a single step being 4PDF Image | TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESS

PDF Search Title:

TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESSOriginal File Name Searched:

36194253.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)