PDF Publication Title:

Text from PDF Page: 099

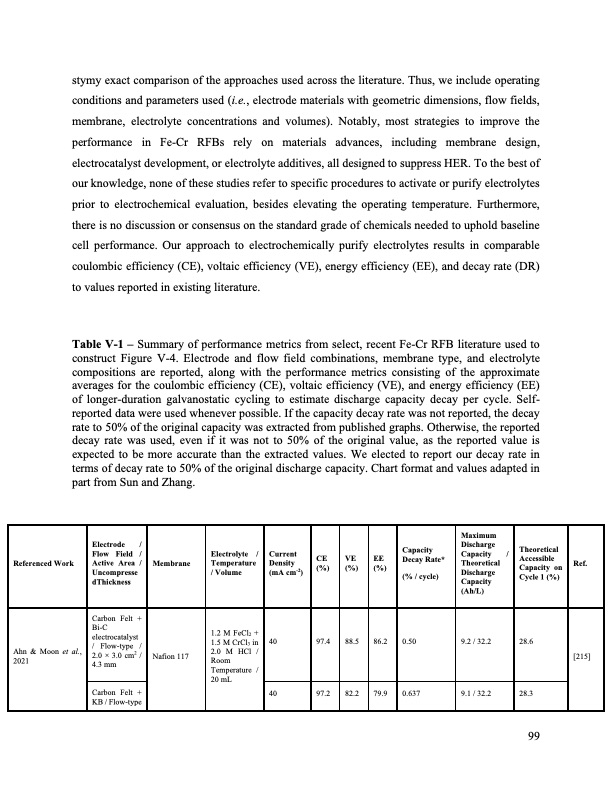

stymy exact comparison of the approaches used across the literature. Thus, we include operating conditions and parameters used (i.e., electrode materials with geometric dimensions, flow fields, membrane, electrolyte concentrations and volumes). Notably, most strategies to improve the performance in Fe-Cr RFBs rely on materials advances, including membrane design, electrocatalyst development, or electrolyte additives, all designed to suppress HER. To the best of our knowledge, none of these studies refer to specific procedures to activate or purify electrolytes prior to electrochemical evaluation, besides elevating the operating temperature. Furthermore, there is no discussion or consensus on the standard grade of chemicals needed to uphold baseline cell performance. Our approach to electrochemically purify electrolytes results in comparable coulombic efficiency (CE), voltaic efficiency (VE), energy efficiency (EE), and decay rate (DR) to values reported in existing literature. Table V-1 – Summary of performance metrics from select, recent Fe-Cr RFB literature used to construct Figure V-4. Electrode and flow field combinations, membrane type, and electrolyte compositions are reported, along with the performance metrics consisting of the approximate averages for the coulombic efficiency (CE), voltaic efficiency (VE), and energy efficiency (EE) of longer-duration galvanostatic cycling to estimate discharge capacity decay per cycle. Self- reported data were used whenever possible. If the capacity decay rate was not reported, the decay rate to 50% of the original capacity was extracted from published graphs. Otherwise, the reported decay rate was used, even if it was not to 50% of the original value, as the reported value is expected to be more accurate than the extracted values. We elected to report our decay rate in terms of decay rate to 50% of the original discharge capacity. Chart format and values adapted in part from Sun and Zhang. Referenced Work Ahn & Moon et al., 2021 Membrane Nafion 117 28.6 28.3 [215] Electrode / Flow Field / Active Area / Uncompresse dThickness Carbon Felt + Bi-C electrocatalyst / Flow-type / 2.0 × 3.0 cm2 / 4.3 mm Carbon Felt + KB / Flow-type Electrolyte / Temperature / Volume 1.2 M FeCl2 + 1.5 M CrCl3 in 2.0MHCl/ Room Temperature / 20 mL Current Density (mA cm-2) 40 40 CE VE EE (%) (%) (%) 97.4 88.5 86.2 97.2 82.2 79.9 Capacity Decay Rate* (% / cycle) 0.50 0.637 Maximum Discharge Capacity Theoretical Discharge Capacity (Ah/L) 9.2 / 32.2 9.1/32.2 / Theoretical Accessible Capacity on Ref. Cycle 1 (%) 99PDF Image | Bringing Redox Flow Batteries to the Grid

PDF Search Title:

Bringing Redox Flow Batteries to the GridOriginal File Name Searched:

Rodby-krodby-phd-chemE-2022-thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |