PDF Publication Title:

Text from PDF Page: 002

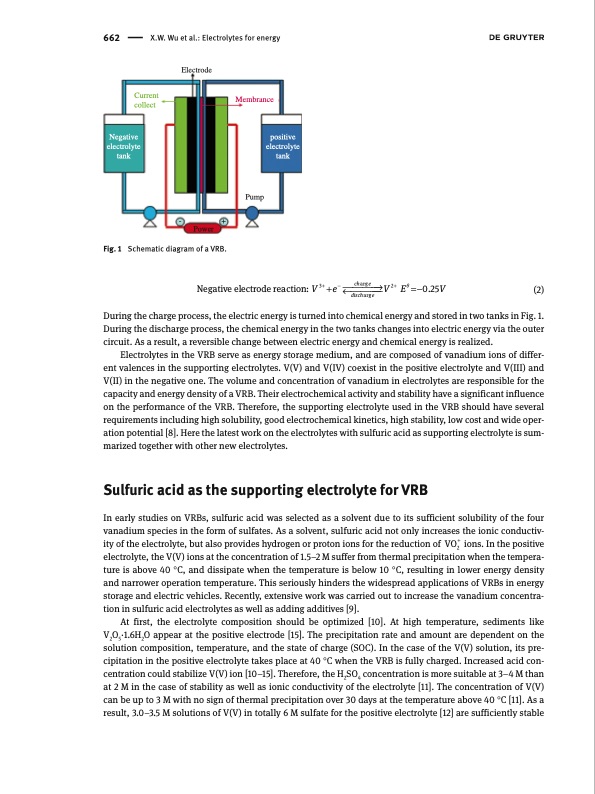

662 X.W. Wu et al.: Electrolytes for energy Electrode Current collect Negative electrolyte tank Membrance positive electrolyte tank Fig. 1 Schematic diagram of a VRB. -+ Power Pump During the charge process, the electric energy is turned into chemical energy and stored in two tanks in Fig. 1. During the discharge process, the chemical energy in the two tanks changes into electric energy via the outer circuit. As a result, a reversible change between electric energy and chemical energy is realized. Electrolytes in the VRB serve as energy storage medium, and are composed of vanadium ions of differ- ent valences in the supporting electrolytes. V(V) and V(IV) coexist in the positive electrolyte and V(III) and V(II) in the negative one. The volume and concentration of vanadium in electrolytes are responsible for the capacity and energy density of a VRB. Their electrochemical activity and stability have a significant influence on the performance of the VRB. Therefore, the supporting electrolyte used in the VRB should have several requirements including high solubility, good electrochemical kinetics, high stability, low cost and wide oper- ation potential [8]. Here the latest work on the electrolytes with sulfuric acid as supporting electrolyte is sum- marized together with other new electrolytes. Sulfuric acid as the supporting electrolyte for VRB In early studies on VRBs, sulfuric acid was selected as a solvent due to its sufficient solubility of the four vanadium species in the form of sulfates. As a solvent, sulfuric acid not only increases the ionic conductiv- electrolyte, the V(V) ions at the concentration of 1.5–2 M suffer from thermal precipitation when the tempera- ture is above 40 °C, and dissipate when the temperature is below 10 °C, resulting in lower energy density and narrower operation temperature. This seriously hinders the widespread applications of VRBs in energy storage and electric vehicles. Recently, extensive work was carried out to increase the vanadium concentra- tion in sulfuric acid electrolytes as well as adding additives [9]. At first, the electrolyte composition should be optimized [10]. At high temperature, sediments like V2O5·1.6H2O appear at the positive electrode [15]. The precipitation rate and amount are dependent on the solution composition, temperature, and the state of charge (SOC). In the case of the V(V) solution, its pre- cipitation in the positive electrolyte takes place at 40 °C when the VRB is fully charged. Increased acid con- centration could stabilize V(V) ion [10–15]. Therefore, the H2SO4 concentration is more suitable at 3–4 M than at 2 M in the case of stability as well as ionic conductivity of the electrolyte [11]. The concentration of V(V) can be up to 3 M with no sign of thermal precipitation over 30 days at the temperature above 40 °C [11]. As a result, 3.0–3.5 M solutions of V(V) in totally 6 M sulfate for the positive electrolyte [12] are sufficiently stable ity of the electrolyte, but also provides hydrogen or proton ions for the reduction of VO+ ions. In the positive 2 charge Negative electrode reaction: V 3+ +e− →V 2+ Eθ =−0.25V (2) ← dischargePDF Image | Electrolytes for vanadium redox flow batteries

PDF Search Title:

Electrolytes for vanadium redox flow batteriesOriginal File Name Searched:

10-1515_pac-2013-1213.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |