PDF Publication Title:

Text from PDF Page: 006

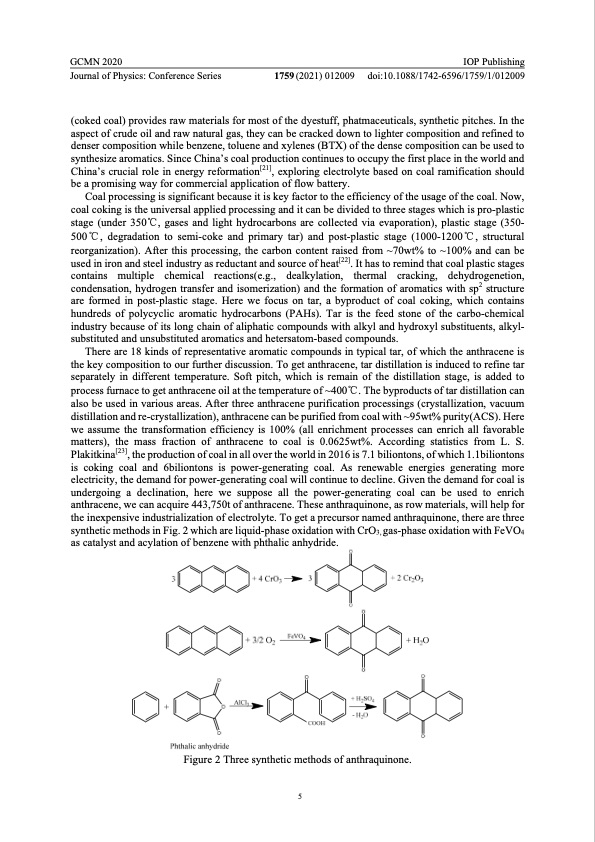

GCMN 2020 IOP Publishing Journal of Physics: Conference Series 1759 (2021) 012009 doi:10.1088/1742-6596/1759/1/012009 (coked coal) provides raw materials for most of the dyestuff, phatmaceuticals, synthetic pitches. In the aspect of crude oil and raw natural gas, they can be cracked down to lighter composition and refined to denser composition while benzene, toluene and xylenes (BTX) of the dense composition can be used to synthesize aromatics. Since China’s coal production continues to occupy the first place in the world and China’s crucial role in energy reformation[21], exploring electrolyte based on coal ramification should be a promising way for commercial application of flow battery. Coal processing is significant because it is key factor to the efficiency of the usage of the coal. Now, coal coking is the universal applied processing and it can be divided to three stages which is pro-plastic stage (under 350°C, gases and light hydrocarbons are collected via evaporation), plastic stage (350- 500°C, degradation to semi-coke and primary tar) and post-plastic stage (1000-1200°C, structural reorganization). After this processing, the carbon content raised from ~70wt% to ~100% and can be used in iron and steel industry as reductant and source of heat[22]. It has to remind that coal plastic stages contains multiple chemical reactions(e.g., dealkylation, thermal cracking, dehydrogenetion, condensation, hydrogen transfer and isomerization) and the formation of aromatics with sp2 structure are formed in post-plastic stage. Here we focus on tar, a byproduct of coal coking, which contains hundreds of polycyclic aromatic hydrocarbons (PAHs). Tar is the feed stone of the carbo-chemical industry because of its long chain of aliphatic compounds with alkyl and hydroxyl substituents, alkyl- substituted and unsubstituted aromatics and hetersatom-based compounds. There are 18 kinds of representative aromatic compounds in typical tar, of which the anthracene is the key composition to our further discussion. To get anthracene, tar distillation is induced to refine tar separately in different temperature. Soft pitch, which is remain of the distillation stage, is added to process furnace to get anthracene oil at the temperature of ~400°C. The byproducts of tar distillation can also be used in various areas. After three anthracene purification processings (crystallization, vacuum distillation and re-crystallization), anthracene can be purified from coal with ~95wt% purity(ACS). Here we assume the transformation efficiency is 100% (all enrichment processes can enrich all favorable matters), the mass fraction of anthracene to coal is 0.0625wt%. According statistics from L. S. Plakitkina[23], the production of coal in all over the world in 2016 is 7.1 biliontons, of which 1.1biliontons is coking coal and 6biliontons is power-generating coal. As renewable energies generating more electricity, the demand for power-generating coal will continue to decline. Given the demand for coal is undergoing a declination, here we suppose all the power-generating coal can be used to enrich anthracene, we can acquire 443,750t of anthracene. These anthraquinone, as row materials, will help for the inexpensive industrialization of electrolyte. To get a precursor named anthraquinone, there are three synthetic methods in Fig. 2 which are liquid-phase oxidation with CrO3, gas-phase oxidation with FeVO4 as catalyst and acylation of benzene with phthalic anhydride. Figure 2 Three synthetic methods of anthraquinone. 5PDF Image | Emerging Aqueous Flow Batteries and Perspectives

PDF Search Title:

Emerging Aqueous Flow Batteries and PerspectivesOriginal File Name Searched:

Zhang_2021_J_Phys_Conf_Ser_1759_012009.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |