PDF Publication Title:

Text from PDF Page: 017

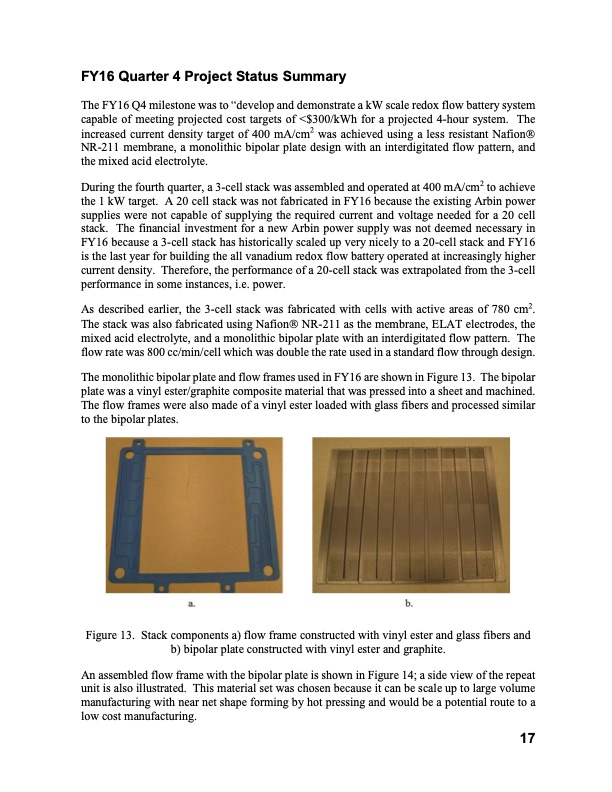

FY16 Quarter 4 Project Status Summary The FY16 Q4 milestone was to “develop and demonstrate a kW scale redox flow battery system capable of meeting projected cost targets of <$300/kWh for a projected 4-hour system. The increased current density target of 400 mA/cm2 was achieved using a less resistant Nafion NR-211 membrane, a monolithic bipolar plate design with an interdigitated flow pattern, and the mixed acid electrolyte. During the fourth quarter, a 3-cell stack was assembled and operated at 400 mA/cm2 to achieve the 1 kW target. A 20 cell stack was not fabricated in FY16 because the existing Arbin power supplies were not capable of supplying the required current and voltage needed for a 20 cell stack. The financial investment for a new Arbin power supply was not deemed necessary in FY16 because a 3-cell stack has historically scaled up very nicely to a 20-cell stack and FY16 is the last year for building the all vanadium redox flow battery operated at increasingly higher current density. Therefore, the performance of a 20-cell stack was extrapolated from the 3-cell performance in some instances, i.e. power. As described earlier, the 3-cell stack was fabricated with cells with active areas of 780 cm2. The stack was also fabricated using Nafion NR-211 as the membrane, ELAT electrodes, the mixed acid electrolyte, and a monolithic bipolar plate with an interdigitated flow pattern. The flow rate was 800 cc/min/cell which was double the rate used in a standard flow through design. The monolithic bipolar plate and flow frames used in FY16 are shown in Figure 13. The bipolar plate was a vinyl ester/graphite composite material that was pressed into a sheet and machined. The flow frames were also made of a vinyl ester loaded with glass fibers and processed similar to the bipolar plates. Figure 13. Stack components a) flow frame constructed with vinyl ester and glass fibers and b) bipolar plate constructed with vinyl ester and graphite. An assembled flow frame with the bipolar plate is shown in Figure 14; a side view of the repeat unit is also illustrated. This material set was chosen because it can be scale up to large volume manufacturing with near net shape forming by hot pressing and would be a potential route to a low cost manufacturing. 17PDF Image | High Current Density Redox Flow Batteries

PDF Search Title:

High Current Density Redox Flow BatteriesOriginal File Name Searched:

PNNL-23819-4.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |