PDF Publication Title:

Text from PDF Page: 050

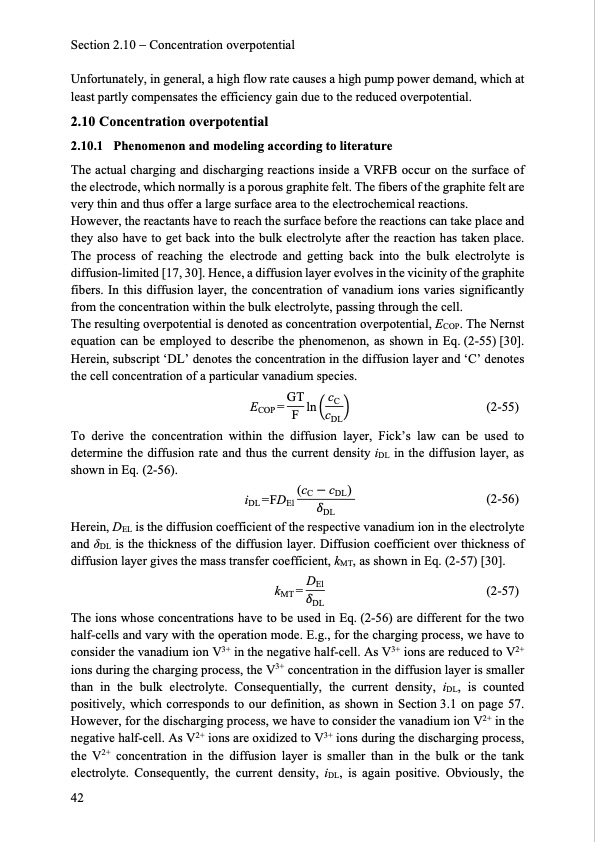

Section 2.10 Concentration overpotential Unfortunately, in general, a high flow rate causes a high pump power demand, which at least partly compensates the efficiency gain due to the reduced overpotential. 2.10 Concentration overpotential 2.10.1 Phenomenon and modeling according to literature The actual charging and discharging reactions inside a VRFB occur on the surface of the electrode, which normally is a porous graphite felt. The fibers of the graphite felt are very thin and thus offer a large surface area to the electrochemical reactions. However, the reactants have to reach the surface before the reactions can take place and they also have to get back into the bulk electrolyte after the reaction has taken place. The process of reaching the electrode and getting back into the bulk electrolyte is diffusion-limited [17, 30]. Hence, a diffusion layer evolves in the vicinity of the graphite fibers. In this diffusion layer, the concentration of vanadium ions varies significantly from the concentration within the bulk electrolyte, passing through the cell. The resulting overpotential is denoted as concentration overpotential, ECOP. The Nernst equation can be employed to describe the phenomenon, as shown in Eq. (2-55) [30]. Herein, subscript ‘DL’ denotes the concentration in the diffusion layer and ‘C’ denotes the cell concentration of a particular vanadium species. ECOP=GTlncC (2-55) F cDL To derive the concentration within the diffusion layer, Fick’s law can be used to determine the diffusion rate and thus the current density iDL in the diffusion layer, as shown in Eq. (2-56). i =FD (cCcDL) (2-56) DL El DL Herein, DEL is the diffusion coefficient of the respective vanadium ion in the electrolyte and δDL is the thickness of the diffusion layer. Diffusion coefficient over thickness of diffusion layer gives the mass transfer coefficient, kMT, as shown in Eq. (2-57) [30]. kMT= DEl (2-57) DL The ions whose concentrations have to be used in Eq. (2-56) are different for the two half-cells and vary with the operation mode. E.g., for the charging process, we have to consider the vanadium ion V3+ in the negative half-cell. As V3+ ions are reduced to V2+ ions during the charging process, the V3+ concentration in the diffusion layer is smaller than in the bulk electrolyte. Consequentially, the current density, iDL, is counted positively, which corresponds to our definition, as shown in Section 3.1 on page 57. However, for the discharging process, we have to consider the vanadium ion V2+ in the negative half-cell. As V2+ ions are oxidized to V3+ ions during the discharging process, the V2+ concentration in the diffusion layer is smaller than in the bulk or the tank electrolyte. Consequently, the current density, iDL, is again positive. Obviously, the 42PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |