PDF Publication Title:

Text from PDF Page: 067

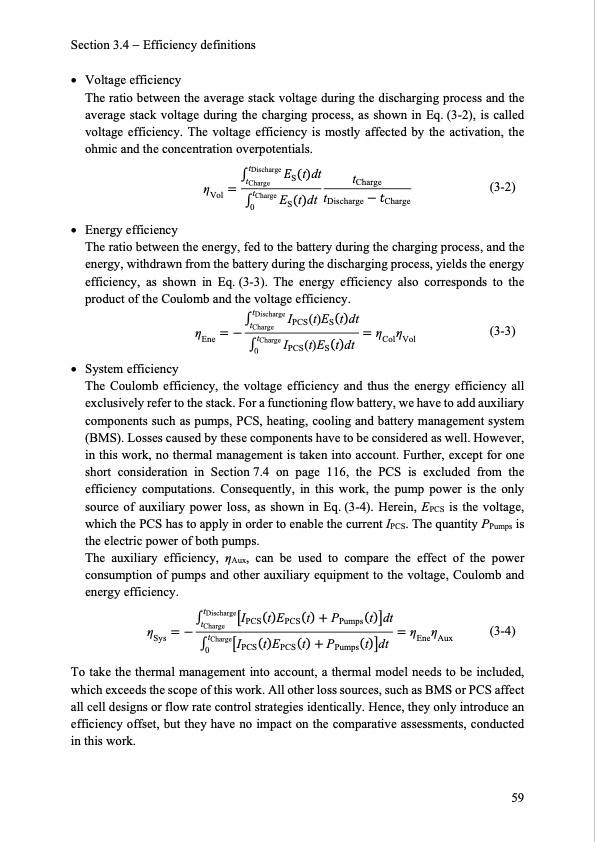

Section 3.4 Efficiency definitions Voltage efficiency The ratio between the average stack voltage during the discharging process and the average stack voltage during the charging process, as shown in Eq. (3-2), is called voltage efficiency. The voltage efficiency is mostly affected by the activation, the ohmic and the concentration overpotentials. tDischarge Stdt t η tCharge Charge Vol tCharge EStdt tDischarge Charge 0 (3-2) Energyefficiency The ratio between the energy, fed to the battery during the charging process, and the energy, withdrawn from the battery during the discharging process, yields the energy efficiency, as shown in Eq. (3-3). The energy efficiency also corresponds to the product of the Coulomb and the voltage efficiency. tDischarge IPCS(t)EStdt η tCharge Ene tCharge IPCS(t)EStdt 0 η η Col Vol (3-3) Systemefficiency The Coulomb efficiency, the voltage efficiency and thus the energy efficiency all exclusively refer to the stack. For a functioning flow battery, we have to add auxiliary components such as pumps, PCS, heating, cooling and battery management system (BMS). Losses caused by these components have to be considered as well. However, in this work, no thermal management is taken into account. Further, except for one short consideration in Section 7.4 on page 116, the PCS is excluded from the efficiency computations. Consequently, in this work, the pump power is the only source of auxiliary power loss, as shown in Eq. (3-4). Herein, EPCS is the voltage, which the PCS has to apply in order to enable the current IPCS. The quantity PPumps is the electric power of both pumps. The auxiliary efficiency, ηAux, can be used to compare the effect of the power consumption of pumps and other auxiliary equipment to the voltage, Coulomb and energy efficiency. tDischargeIPCStEPCSt PPumpstdt η tCharge Sys tChargeIPCStEPCSt PPumpstdt 0 η η Ene Aux (3-4) To take the thermal management into account, a thermal model needs to be included, which exceeds the scope of this work. All other loss sources, such as BMS or PCS affect all cell designs or flow rate control strategies identically. Hence, they only introduce an efficiency offset, but they have no impact on the comparative assessments, conducted in this work. 59PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |