PDF Publication Title:

Text from PDF Page: 096

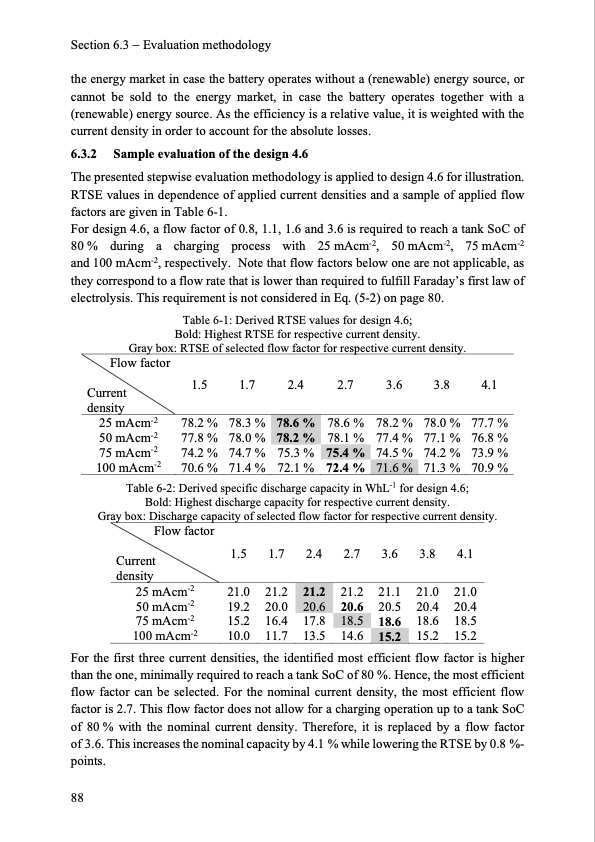

Section 6.3 Evaluation methodology the energy market in case the battery operates without a (renewable) energy source, or cannot be sold to the energy market, in case the battery operates together with a (renewable) energy source. As the efficiency is a relative value, it is weighted with the current density in order to account for the absolute losses. 6.3.2 Sample evaluation of the design 4.6 The presented stepwise evaluation methodology is applied to design 4.6 for illustration. RTSE values in dependence of applied current densities and a sample of applied flow factors are given in Table 6-1. For design 4.6, a flow factor of 0.8, 1.1, 1.6 and 3.6 is required to reach a tank SoC of 80 % during a charging process with 25 mAcm-2, 50 mAcm-2, 75 mAcm-2 and 100 mAcm-2, respectively. Note that flow factors below one are not applicable, as they correspond to a flow rate that is lower than required to fulfill Faraday’s first law of electrolysis. This requirement is not considered in Eq. (5-2) on page 80. Table 6-1: Derived RTSE values for design 4.6; Bold: Highest RTSE for respective current density. Gray box: RTSE of selected flow factor for respective current density. Flow factor Current density 25mAcm-2 50mAcm-2 75mAcm-2 100mAcm-2 Table 6-2: Derived specific discharge capacity in WhL-1 for design 4.6; Bold: Highest discharge capacity for respective current density. Gray box: Discharge capacity of selected flow factor for respective current density. 1.5 1.7 2.4 2.7 3.6 3.8 4.1 78.2% 78.3% 77.8% 78.0% 74.2% 74.7% 75.3% 75.4% 74.5% 74.2% 73.9% 70.6% 71.4% 72.1% 72.4% 71.6% 71.3% 70.9% 78.6% 78.2% 78.0% 77.7% 78.1% 77.4% 77.1% 76.8% Flow factor Current density 25 mAcm-2 50 mAcm-2 75 mAcm-2 100 mAcm-2 1.5 1.7 2.4 2.7 3.6 3.8 4.1 21.0 21.2 21.2 20.6 21.2 21.1 21.0 21.0 19.2 20.0 20.6 20.5 20.4 20.4 15.2 16.4 17.8 18.5 18.6 18.6 18.5 10.0 11.7 13.5 14.6 15.2 15.2 15.2 For the first three current densities, the identified most efficient flow factor is higher than the one, minimally required to reach a tank SoC of 80 %. Hence, the most efficient flow factor can be selected. For the nominal current density, the most efficient flow factor is 2.7. This flow factor does not allow for a charging operation up to a tank SoC of 80 % with the nominal current density. Therefore, it is replaced by a flow factor of 3.6. This increases the nominal capacity by 4.1 % while lowering the RTSE by 0.8 %- points. 88 78.6 % 78.2 %PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |