PDF Publication Title:

Text from PDF Page: 006

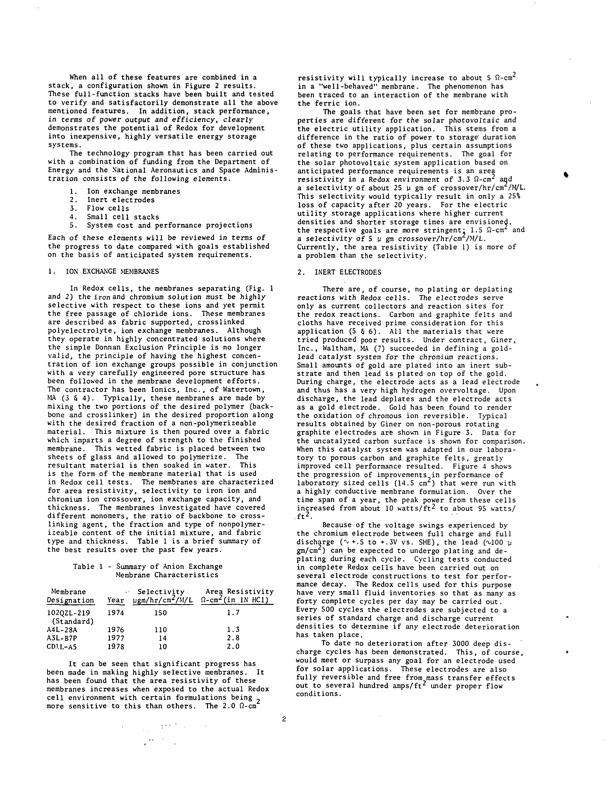

When all of these features are combined in a stack, a configuration shown in Figure 2 results. These full-function stacks have been built and tested to verify and satisfactorily demonstrate all the above mentionedfeatures. Inaddition,stackperformance, in terms of power output and efficiency, clearly demonstrates the potential of Redox for development into inexpensive, highly versatile energy storage systems. The technology program that has been carried out with a combination of funding from the Department of Energy and the National Aeronautics and Space Adminis- tration consists of the following elements. 1. Ion exchange membranes 2. Inert electrodes 3. Flowcells 4. Small cell stacks 5. System cost and performance projections Each of these elements will be reviewed in terms of the progress to date compared with goals established on the basis of anticipated system requirements. 1. IONEXCHANGE.MEMBRANES In Redox cells, the membranes separating (Fig. 1 and 2) the ironand chromium solution must be highly selective with respect to these ions and yet permit the free passage of chloride ions. These membranes are described as fabric supported, crosslinked polyelectrolyte,ionexchangemembranes. Although they operate in highly concentrated solutions where the simple Donnan Exclusion Principle is no longer valid, the principle of having the highest concen- tration of ion exchange groups possible in conjunction with a very carefully engineered pore structure has been followed in the membrane development efforts. The contractor has been Ionics, Inc., of Watertown, MA(364). Typically,thesemembranesaremadeby mixing the two portions of the desired polymer (back- bone and crosslinker) in the desired proportion along with the desired fraction of a non-polymerizeable material. This mixture is then poured over a fabric which imparts a degree of strength to the finished membrane. Thiswettedfabricisplacedbetweentwo sheetsofglassandallowedtopolymerize. The resultant material is then soaked in water. This is the form of the membrane material that is used inRedoxcelltests. Themembranesarecharacterized for area resistivity, selectivity to iron ion and chromium ion crossover, ion exchange capacity, and thickness. The membranes investigated have covered different monomers, the ratio of backbone to cross- linking agent, the fraction and type of nonpolymer- izeable content of the initial mixture, and fabric typeandthickness. Table1isabriefsummaryof the best results over the past few years. Table 1 - Summary of Anion Exchange Membrane Characteristics resistivity will typically increase to about 5 fi-cnr in a "well-behaved" membrane. The phenomenon has been traced to an interaction of the membrane with the ferricion. Thegoalsthathavebeensetformembranepro- perties are different for the solar photovoltaic and the electric utility application. This stems from a difference in the ratio of power to storage' duration of these two applications, plus certain assumptions relating to performance requirements. The goal for the solar photovoltaic system application based on anticipated performance requirements is an area resistivity in a Redox environment of 3.3 fl-cm2 and a selectivity of about 25 y gm of crossover/hr/cm /M/L. This selectivity would typically result in only a 25% lossofcapacityafter20years. Fortheelectric utility storage applications where higher current densities and shorter storage times are envisioned, the respective goals are more stringent- 1.5 ft-cnr and a selectivity of 5 v gm crossover/hr/cm /M/L. Currently, the area resistivity (Table 1) is more of a problem than theselectivity. 2. INERTELECTRODES There are, of course, no plating or deplating reactions with Redox cells. The electrodes serve only as current collectors and reaction sites for the redox reactions. Carbon and graphite felts and cloths have received prime consideration for this application(566). Allthematerialsthatwere tried produced poor results. Under contract, Giner, Inc., Waltham, MA (7) succeeded in defining a gold- lead catalyst system for the chromium reactions. Small amounts of gold are plated into an inert sub- strate and then lead is plated on top of the gold. During charge, the electrode acts as a lead electrode and thus has a very high hydrogen overvoltage. Upon discharge,theleaddeplatesandtheelectrodeacts as a gold electrode. Gold has been found to render the oxidation of chromous ion reversible. Typical results obtained by Giner on non-porous rotating graphite electrodes are shown in Figure 3. Data for the uncatalyzed carbon surface is shown for comparison. Whenthiscatalystsystemwasadaptedinourlabora- torytoporouscarbonandgraphitefelts,greatly- improved cell performance resulted. Figure 4 shows the progression of improvements in performance of laboratorysizedcells(14.5cm)thatwererunwith a highly conductive membrane formulation. Over the time span of a year, the peak power from these cells increased from about 10 watts/ft2 to about 95 watts/ .ft2. Because of the voltage swings experienced by the chromium electrode between full charge and full discharge("v+.5to+.3Vvs.SHE),thelead(MOOp gm/cm2) can be expected to undergo plating and de- platingduringeachcycle. Cyclingtestsconducted in complete Redox cells have been carried out on several electrode constructions to test for perfor- mance decay. The Redox cells used for this purpose have very small fluid inventories so that as many as forty complete cycles per day may be carried out. Every 500 cycles the electrodes are subjected to a series of standard charge and discharge current densities to determine if any electrode deterioration has taken place. To date no deterioration after 3000 deep dis- charge cycles has been demonstrated. This, of course, would meet or surpass any goal for an electrode used for solar applications. These electrodes are also fully reversible and free from^mass transfer effects out to several hundred amps/ft" under proper flow conditions. Membrane Designation Year ugm/hr/cm/M/L n-cm(in INHC1) • Selectivity Area Resistivity z2 102QZL-219 1974 150 1.7 (Standard) A4L-28A 1976 110 1.3 A3L-B7P 1977 14 2.8 CD.1.L-A5 1978 10 2.0 It can be seen that significant progress has beenmadeinmakinghighlyselectivemembranes. It has been found that the area resistivity of these membranes increases when exposed to the actual Redox cell environment with certain formulations being . moresensitivetothisthanothers. The2.0ft-cmPDF Image | RECENT ADVANCES IN REDOX FLOW CELL STORAGE SYSTEMS

PDF Search Title:

RECENT ADVANCES IN REDOX FLOW CELL STORAGE SYSTEMSOriginal File Name Searched:

19790018334.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |