PDF Publication Title:

Text from PDF Page: 002

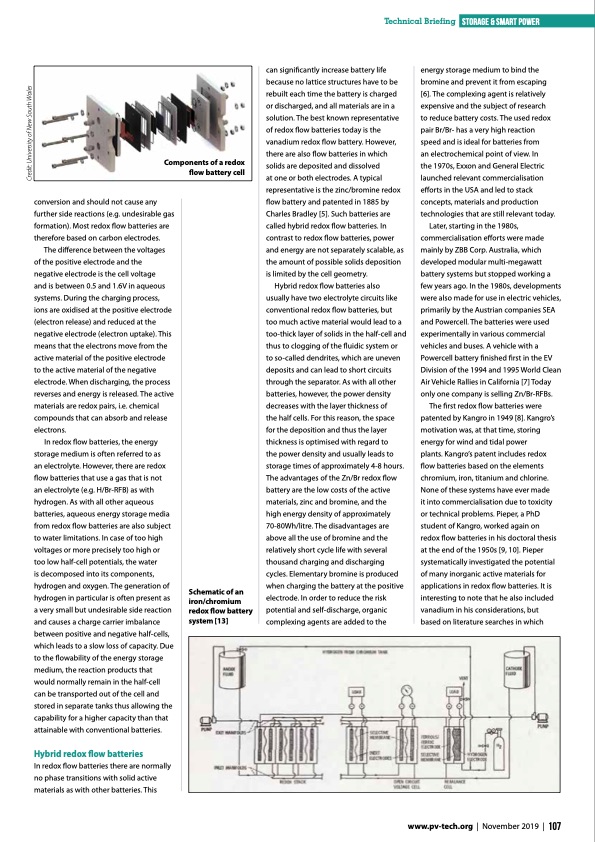

Components of a redox flow battery cell conversion and should not cause any further side reactions (e.g. undesirable gas formation). Most redox flow batteries are therefore based on carbon electrodes. The difference between the voltages of the positive electrode and the negative electrode is the cell voltage and is between 0.5 and 1.6V in aqueous systems. During the charging process, ions are oxidised at the positive electrode (electron release) and reduced at the negative electrode (electron uptake). This means that the electrons move from the active material of the positive electrode to the active material of the negative electrode. When discharging, the process reverses and energy is released. The active materials are redox pairs, i.e. chemical compounds that can absorb and release electrons. In redox flow batteries, the energy storage medium is often referred to as an electrolyte. However, there are redox flow batteries that use a gas that is not an electrolyte (e.g. H/Br-RFB) as with hydrogen. As with all other aqueous batteries, aqueous energy storage media from redox flow batteries are also subject to water limitations. In case of too high voltages or more precisely too high or too low half-cell potentials, the water is decomposed into its components, hydrogen and oxygen. The generation of hydrogen in particular is often present as a very small but undesirable side reaction and causes a charge carrier imbalance between positive and negative half-cells, which leads to a slow loss of capacity. Due to the flowability of the energy storage medium, the reaction products that would normally remain in the half-cell can be transported out of the cell and stored in separate tanks thus allowing the capability for a higher capacity than that attainable with conventional batteries. Hybrid redox flow batteries In redox flow batteries there are normally no phase transitions with solid active materials as with other batteries. This Schematic of an iron/chromium redox flow battery system [13] can significantly increase battery life because no lattice structures have to be rebuilt each time the battery is charged or discharged, and all materials are in a solution. The best known representative of redox flow batteries today is the vanadium redox flow battery. However, there are also flow batteries in which solids are deposited and dissolved at one or both electrodes. A typical representative is the zinc/bromine redox flow battery and patented in 1885 by Charles Bradley [5]. Such batteries are called hybrid redox flow batteries. In contrast to redox flow batteries, power and energy are not separately scalable, as the amount of possible solids deposition is limited by the cell geometry. Hybrid redox flow batteries also usually have two electrolyte circuits like conventional redox flow batteries, but too much active material would lead to a too-thick layer of solids in the half-cell and thus to clogging of the fluidic system or to so-called dendrites, which are uneven deposits and can lead to short circuits through the separator. As with all other batteries, however, the power density decreases with the layer thickness of the half cells. For this reason, the space for the deposition and thus the layer thickness is optimised with regard to the power density and usually leads to storage times of approximately 4-8 hours. The advantages of the Zn/Br redox flow battery are the low costs of the active materials, zinc and bromine, and the high energy density of approximately 70-80Wh/litre. The disadvantages are above all the use of bromine and the relatively short cycle life with several thousand charging and discharging cycles. Elementary bromine is produced when charging the battery at the positive electrode. In order to reduce the risk potential and self-discharge, organic complexing agents are added to the energy storage medium to bind the bromine and prevent it from escaping [6]. The complexing agent is relatively expensive and the subject of research to reduce battery costs. The used redox pair Br/Br- has a very high reaction speed and is ideal for batteries from an electrochemical point of view. In the 1970s, Exxon and General Electric launched relevant commercialisation efforts in the USA and led to stack concepts, materials and production technologies that are still relevant today. Later, starting in the 1980s, commercialisation efforts were made mainly by ZBB Corp. Australia, which developed modular multi-megawatt battery systems but stopped working a few years ago. In the 1980s, developments were also made for use in electric vehicles, primarily by the Austrian companies SEA and Powercell. The batteries were used experimentally in various commercial vehicles and buses. A vehicle with a Powercell battery finished first in the EV Division of the 1994 and 1995 World Clean Air Vehicle Rallies in California [7] Today only one company is selling Zn/Br-RFBs. The first redox flow batteries were patented by Kangro in 1949 [8]. Kangro’s motivation was, at that time, storing energy for wind and tidal power plants. Kangro’s patent includes redox flow batteries based on the elements chromium, iron, titanium and chlorine. None of these systems have ever made it into commercialisation due to toxicity or technical problems. Pieper, a PhD student of Kangro, worked again on redox flow batteries in his doctoral thesis at the end of the 1950s [9, 10]. Pieper systematically investigated the potential of many inorganic active materials for applications in redox flow batteries. It is interesting to note that he also included vanadium in his considerations, but based on literature searches in which Technical Briefing www.pv-tech.org | November 2019 | 107 Storage & smart power Credit: University of New South WalesPDF Image | Redox flow batteries for renewable energy storage

PDF Search Title:

Redox flow batteries for renewable energy storageOriginal File Name Searched:

Redox-flow-batteries.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |