PDF Publication Title:

Text from PDF Page: 128

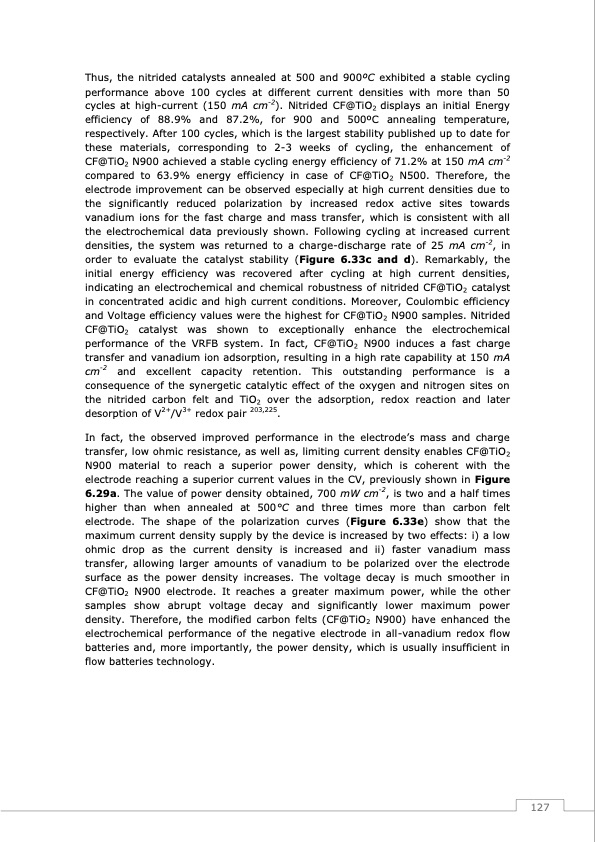

Thus, the nitrided catalysts annealed at 500 and 900oC exhibited a stable cycling performance above 100 cycles at different current densities with more than 50 cycles at high-current (150 mA cm-2). Nitrided CF@TiO2 displays an initial Energy efficiency of 88.9% and 87.2%, for 900 and 500oC annealing temperature, respectively. After 100 cycles, which is the largest stability published up to date for these materials, corresponding to 2-3 weeks of cycling, the enhancement of CF@TiO2 N900 achieved a stable cycling energy efficiency of 71.2% at 150 mA cm-2 compared to 63.9% energy efficiency in case of CF@TiO2 N500. Therefore, the electrode improvement can be observed especially at high current densities due to the significantly reduced polarization by increased redox active sites towards vanadium ions for the fast charge and mass transfer, which is consistent with all the electrochemical data previously shown. Following cycling at increased current densities, the system was returned to a charge-discharge rate of 25 mA cm-2, in order to evaluate the catalyst stability (Figure 6.33c and d). Remarkably, the initial energy efficiency was recovered after cycling at high current densities, indicating an electrochemical and chemical robustness of nitrided CF@TiO2 catalyst in concentrated acidic and high current conditions. Moreover, Coulombic efficiency and Voltage efficiency values were the highest for CF@TiO2 N900 samples. Nitrided CF@TiO2 catalyst was shown to exceptionally enhance the electrochemical performance of the VRFB system. In fact, CF@TiO2 N900 induces a fast charge transfer and vanadium ion adsorption, resulting in a high rate capability at 150 mA cm-2 and excellent capacity retention. This outstanding performance is a consequence of the synergetic catalytic effect of the oxygen and nitrogen sites on the nitrided carbon felt and TiO2 over the adsorption, redox reaction and later desorption of V2+/V3+ redox pair 203,225. In fact, the observed improved performance in the electrode’s mass and charge transfer, low ohmic resistance, as well as, limiting current density enables CF@TiO2 N900 material to reach a superior power density, which is coherent with the electrode reaching a superior current values in the CV, previously shown in Figure 6.29a. The value of power density obtained, 700 mW cm-2, is two and a half times higher than when annealed at 500°C and three times more than carbon felt electrode. The shape of the polarization curves (Figure 6.33e) show that the maximum current density supply by the device is increased by two effects: i) a low ohmic drop as the current density is increased and ii) faster vanadium mass transfer, allowing larger amounts of vanadium to be polarized over the electrode surface as the power density increases. The voltage decay is much smoother in CF@TiO2 N900 electrode. It reaches a greater maximum power, while the other samples show abrupt voltage decay and significantly lower maximum power density. Therefore, the modified carbon felts (CF@TiO2 N900) have enhanced the electrochemical performance of the negative electrode in all-vanadium redox flow batteries and, more importantly, the power density, which is usually insufficient in flow batteries technology. 127PDF Image | Redox Flow Batteries Vanadium to Earth Quinones

PDF Search Title:

Redox Flow Batteries Vanadium to Earth QuinonesOriginal File Name Searched:

FJVG_TESIS.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |