PDF Publication Title:

Text from PDF Page: 041

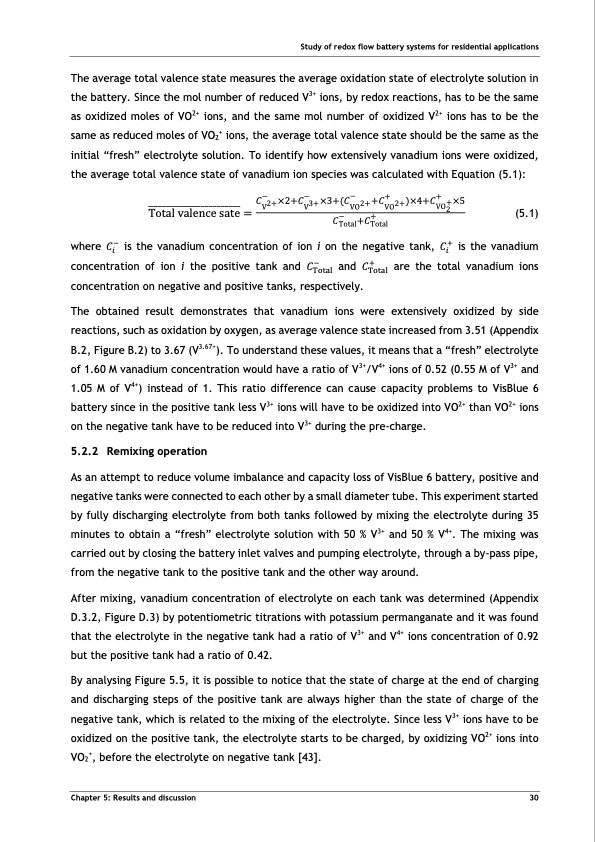

Study of redox flow battery systems for residential applications The average total valence state measures the average oxidation state of electrolyte solution in the battery. Since the mol number of reduced V3+ ions, by redox reactions, has to be the same as oxidized moles of VO2+ ions, and the same mol number of oxidized V2+ ions has to be the same as reduced moles of VO2+ ions, the average total valence state should be the same as the initial “fresh” electrolyte solution. To identify how extensively vanadium ions were oxidized, the average total valence state of vanadium ion species was calculated with Equation (5.1): 𝐶− ×2+𝐶− ×3+(𝐶− +𝐶+ )×4+𝐶+ ×5 ̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ V2+ V3+ VO2+ Total valence sate = 𝐶− +𝐶+ VO2+ VO+ 2 (5.1) where 𝐶− is the vanadium concentration of ion i on the negative tank, 𝐶+ is the vanadium 𝑖𝑖 concentration of ion i the positive tank and 𝐶− and 𝐶+ are the total vanadium ions concentration on negative and positive tanks, respectively. The obtained result demonstrates that vanadium ions were extensively oxidized by side reactions, such as oxidation by oxygen, as average valence state increased from 3.51 (Appendix B.2, Figure B.2) to 3.67 (V3.67+). To understand these values, it means that a “fresh” electrolyte of 1.60 M vanadium concentration would have a ratio of V3+/V4+ ions of 0.52 (0.55 M of V3+ and 1.05 M of V4+) instead of 1. This ratio difference can cause capacity problems to VisBlue 6 battery since in the positive tank less V3+ ions will have to be oxidized into VO2+ than VO2+ ions on the negative tank have to be reduced into V3+ during the pre-charge. 5.2.2 Remixing operation As an attempt to reduce volume imbalance and capacity loss of VisBlue 6 battery, positive and negative tanks were connected to each other by a small diameter tube. This experiment started by fully discharging electrolyte from both tanks followed by mixing the electrolyte during 35 minutes to obtain a “fresh” electrolyte solution with 50 % V3+ and 50 % V4+. The mixing was carried out by closing the battery inlet valves and pumping electrolyte, through a by-pass pipe, from the negative tank to the positive tank and the other way around. After mixing, vanadium concentration of electrolyte on each tank was determined (Appendix D.3.2, Figure D.3) by potentiometric titrations with potassium permanganate and it was found that the electrolyte in the negative tank had a ratio of V3+ and V4+ ions concentration of 0.92 but the positive tank had a ratio of 0.42. By analysing Figure 5.5, it is possible to notice that the state of charge at the end of charging and discharging steps of the positive tank are always higher than the state of charge of the negative tank, which is related to the mixing of the electrolyte. Since less V3+ ions have to be oxidized on the positive tank, the electrolyte starts to be charged, by oxidizing VO2+ ions into VO2+, before the electrolyte on negative tank [43]. Total Total Total Total Chapter 5: Results and discussion 30PDF Image | Tubular Vanadium Air Redox‐flow battery

PDF Search Title:

Tubular Vanadium Air Redox‐flow batteryOriginal File Name Searched:

204521.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |