PDF Publication Title:

Text from PDF Page: 064

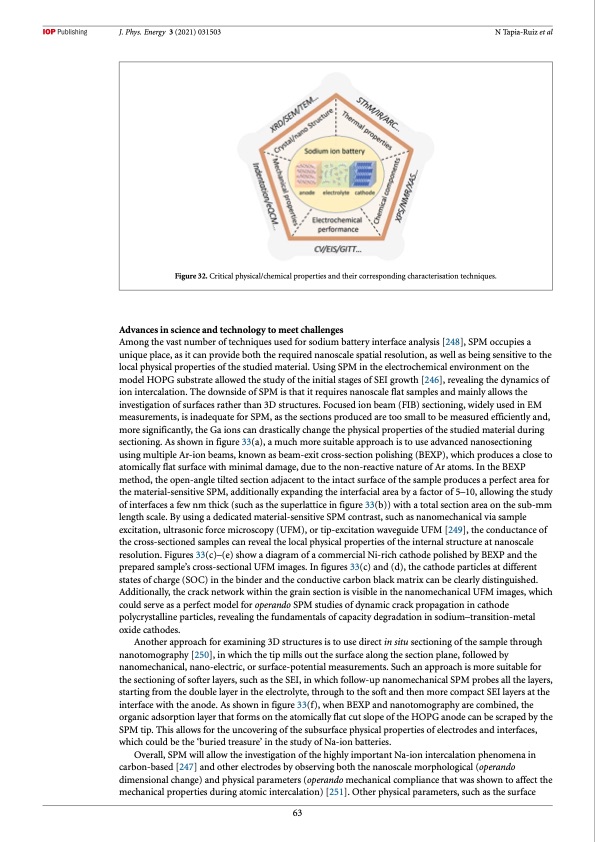

J. Phys. Energy 3 (2021) 031503 N Tapia-Ruiz et al Figure 32. Critical physical/chemical properties and their corresponding characterisation techniques. Advances in science and technology to meet challenges Among the vast number of techniques used for sodium battery interface analysis [248], SPM occupies a unique place, as it can provide both the required nanoscale spatial resolution, as well as being sensitive to the local physical properties of the studied material. Using SPM in the electrochemical environment on the model HOPG substrate allowed the study of the initial stages of SEI growth [246], revealing the dynamics of ion intercalation. The downside of SPM is that it requires nanoscale flat samples and mainly allows the investigation of surfaces rather than 3D structures. Focused ion beam (FIB) sectioning, widely used in EM measurements, is inadequate for SPM, as the sections produced are too small to be measured efficiently and, more significantly, the Ga ions can drastically change the physical properties of the studied material during sectioning. As shown in figure 33(a), a much more suitable approach is to use advanced nanosectioning using multiple Ar-ion beams, known as beam-exit cross-section polishing (BEXP), which produces a close to atomically flat surface with minimal damage, due to the non-reactive nature of Ar atoms. In the BEXP method, the open-angle tilted section adjacent to the intact surface of the sample produces a perfect area for the material-sensitive SPM, additionally expanding the interfacial area by a factor of 5–10, allowing the study of interfaces a few nm thick (such as the superlattice in figure 33(b)) with a total section area on the sub-mm length scale. By using a dedicated material-sensitive SPM contrast, such as nanomechanical via sample excitation, ultrasonic force microscopy (UFM), or tip-excitation waveguide UFM [249], the conductance of the cross-sectioned samples can reveal the local physical properties of the internal structure at nanoscale resolution. Figures 33(c)–(e) show a diagram of a commercial Ni-rich cathode polished by BEXP and the prepared sample’s cross-sectional UFM images. In figures 33(c) and (d), the cathode particles at different states of charge (SOC) in the binder and the conductive carbon black matrix can be clearly distinguished. Additionally, the crack network within the grain section is visible in the nanomechanical UFM images, which could serve as a perfect model for operando SPM studies of dynamic crack propagation in cathode polycrystalline particles, revealing the fundamentals of capacity degradation in sodium–transition-metal oxide cathodes. Another approach for examining 3D structures is to use direct in situ sectioning of the sample through nanotomography [250], in which the tip mills out the surface along the section plane, followed by nanomechanical, nano-electric, or surface-potential measurements. Such an approach is more suitable for the sectioning of softer layers, such as the SEI, in which follow-up nanomechanical SPM probes all the layers, starting from the double layer in the electrolyte, through to the soft and then more compact SEI layers at the interface with the anode. As shown in figure 33(f), when BEXP and nanotomography are combined, the organic adsorption layer that forms on the atomically flat cut slope of the HOPG anode can be scraped by the SPM tip. This allows for the uncovering of the subsurface physical properties of electrodes and interfaces, which could be the ‘buried treasure’ in the study of Na-ion batteries. Overall, SPM will allow the investigation of the highly important Na-ion intercalation phenomena in carbon-based [247] and other electrodes by observing both the nanoscale morphological (operando dimensional change) and physical parameters (operando mechanical compliance that was shown to affect the mechanical properties during atomic intercalation) [251]. Other physical parameters, such as the surface 63PDF Image | 2021 roadmap for sodium-ion batteries

PDF Search Title:

2021 roadmap for sodium-ion batteriesOriginal File Name Searched:

roadmap-sodium-ion-batteries_031503.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |