PDF Publication Title:

Text from PDF Page: 002

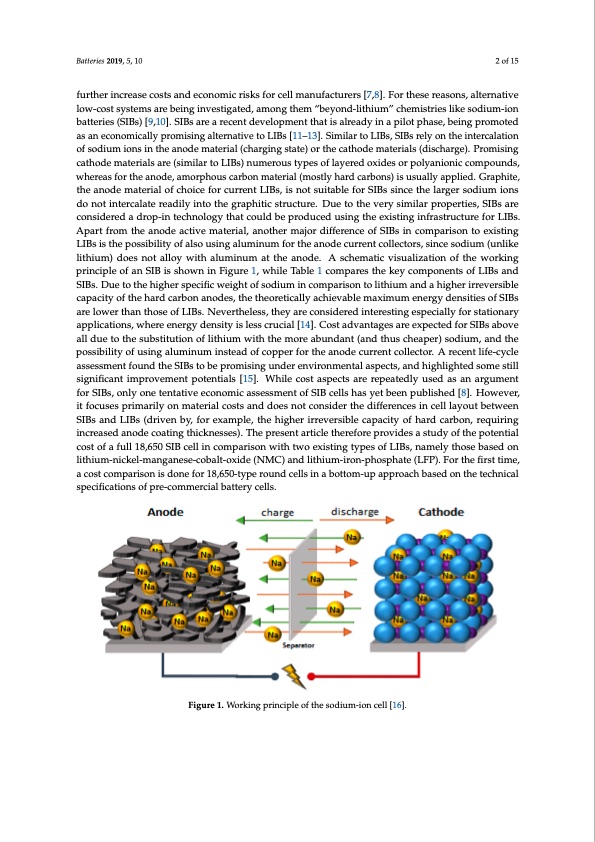

Batteries 2019, 5, x FOR PEER REVIEW 2 of 15 Batteries 2019, 5, 10 2 of 15 concerns about the medium-term availability of certain raw materials like cobalt or lithium, where price peaks or supply shortages might further increase costs and economic risks for cell manufacturers [7,8]. For these reasons, alternative low-cost systems are being investigated, among further increase costs and economic risks for cell manufacturers [7,8]. For these reasons, alternative them “beyond-lithium” chemistries like sodium-ion batteries (SIBs) [9,10]. SIBs are a recent low-cost systems are being investigated, among them “beyond-lithium” chemistries like sodium-ion development that is already in a pilot phase, being promoted as an economically promising batteries (SIBs) [9,10]. SIBs are a recent development that is already in a pilot phase, being promoted alternative to LIBs [11–13]. Similar to LIBs, SIBs rely on the intercalation of sodium ions in the as an economically promising alternative to LIBs [11–13]. Similar to LIBs, SIBs rely on the intercalation anode material (charging state) or the cathode materials (discharge). Promising cathode materials of sodium ions in the anode material (charging state) or the cathode materials (discharge). Promising are (similar to LIBs) numerous types of layered oxides or polyanionic compounds, whereas for the cathode materials are (similar to LIBs) numerous types of layered oxides or polyanionic compounds, anode, amorphous carbon material (mostly hard carbons) is usually applied. Graphite, the anode whereas for the anode, amorphous carbon material (mostly hard carbons) is usually applied. Graphite, material of choice for current LIBs, is not suitable for SIBs since the larger sodium ions do not the anode material of choice for current LIBs, is not suitable for SIBs since the larger sodium ions intercalate readily into the graphitic structure. Due to the very similar properties, SIBs are do not intercalate readily into the graphitic structure. Due to the very similar properties, SIBs are considered a drop-in technology that could be produced using the existing infrastructure for LIBs. considered a drop-in technology that could be produced using the existing infrastructure for LIBs. Apart from the anode active material, another major difference of SIBs in comparison to existing Apart from the anode active material, another major difference of SIBs in comparison to existing LIBs is the possibility of also using aluminum for the anode current collectors, since sodium (unlike LIBs is the possibility of also using aluminum for the anode current collectors, since sodium (unlike lithium) does not alloy with aluminum at the anode. A schematic visualization of the working lithium) does not alloy with aluminum at the anode. A schematic visualization of the working principle of an SIB is shown in Figure 1, while Table 1 compares the key components of LIBs and principle of an SIB is shown in Figure 1, while Table 1 compares the key components of LIBs and SIBs. Due to the higher specific weight of sodium in comparison to lithium and a higher irreversible SIBs. Due to the higher specific weight of sodium in comparison to lithium and a higher irreversible capacity of the hard carbon anodes, the theoretically achievable maximum energy densities of SIBs capacity of the hard carbon anodes, the theoretically achievable maximum energy densities of SIBs are lower than those of LIBs. Nevertheless, they are considered interesting especially for stationary are lower than those of LIBs. Nevertheless, they are considered interesting especially for stationary applications, where energy density is less crucial [14]. Cost advantages are expected for SIBs above applications, where energy density is less crucial [14]. Cost advantages are expected for SIBs above all due to the substitution of lithium with the more abundant (and thus cheaper) sodium, and the all due to the substitution of lithium with the more abundant (and thus cheaper) sodium, and the possibility of using aluminum instead of copper for the anode current collector. A recent life-cycle possibility of using aluminum instead of copper for the anode current collector. A recent life-cycle assessment found the SIBs to be promising under environmental aspects, and highlighted some still assessment found the SIBs to be promising under environmental aspects, and highlighted some still significant improvement potentials [15]. While cost aspects are repeatedly used as an argument for significant improvement potentials [15]. While cost aspects are repeatedly used as an argument SIBs, only one tentative economic assessment of SIB cells has yet been published [8]. However, it for SIBs, only one tentative economic assessment of SIB cells has yet been published [8]. However, focuses primarily on material costs and does not consider the differences in cell layout between SIBs it focuses primarily on material costs and does not consider the differences in cell layout between and LIBs (driven by, for example, the higher irreversible capacity of hard carbon, requiring SIBs and LIBs (driven by, for example, the higher irreversible capacity of hard carbon, requiring increased anode coating thicknesses). The present article therefore provides a study of the potential increased anode coating thicknesses). The present article therefore provides a study of the potential cost of a full 18,650 SIB cell in comparison with two existing types of LIBs, namely those based on cost of a full 18,650 SIB cell in comparison with two existing types of LIBs, namely those based on lithium-nickel-manganese-cobalt-oxide (NMC) and lithium-iron-phosphate (LFP). For the first time, lithium-nickel-manganese-cobalt-oxide (NMC) and lithium-iron-phosphate (LFP). For the first time, a cost comparison is done for 18,650-type round cells in a bottom-up approach based on the a cost comparison is done for 18,650-type round cells in a bottom-up approach based on the technical technical specifications of pre-commercial battery cells. specifications of pre-commercial battery cells. Figure 1. Working principle of the sodium-ion cell [16]. Figure 1. Working principle of the sodium-ion cell [16].PDF Image | Exploring the Economic Potential of Sodium-Ion Batteries

PDF Search Title:

Exploring the Economic Potential of Sodium-Ion BatteriesOriginal File Name Searched:

Exploring_the_Economic_Potential_of_Sodium-Ion_Bat.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |