PDF Publication Title:

Text from PDF Page: 006

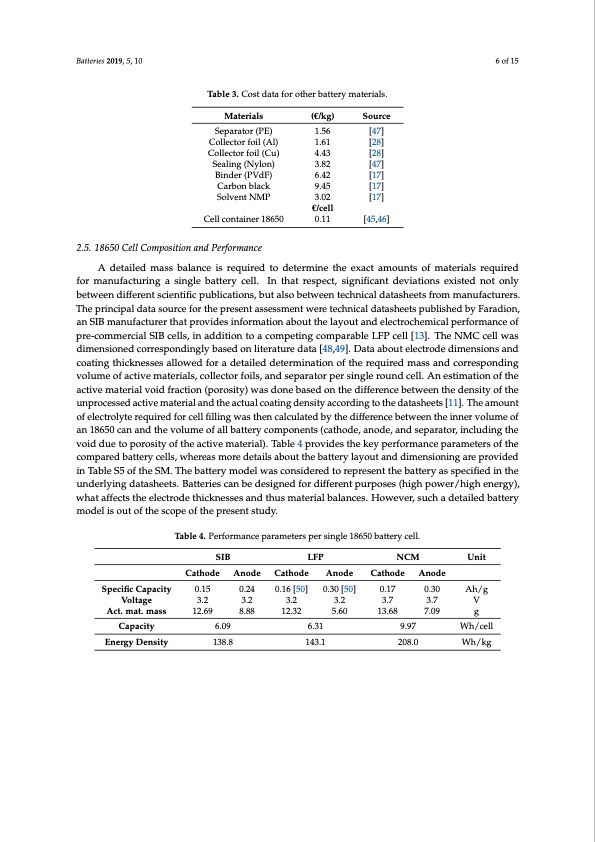

Batteries 2019, 5, 10 6 of 15 Table 3. Cost data for other battery materials. Materials Separator (PE) Collector foil (Al) Collector foil (Cu) Sealing (Nylon) Binder (PVdF) Carbon black Solvent NMP Cell container 18650 2.5. 18650 Cell Composition and Performance (€/kg) Source 1.56 [47] 1.61 [28] 4.43 [28] 3.82 [47] 6.42 [17] 9.45 [17] 3.02 [17] €/cell 0.11 [45,46] A detailed mass balance is required to determine the exact amounts of materials required for manufacturing a single battery cell. In that respect, significant deviations existed not only between different scientific publications, but also between technical datasheets from manufacturers. The principal data source for the present assessment were technical datasheets published by Faradion, an SIB manufacturer that provides information about the layout and electrochemical performance of pre-commercial SIB cells, in addition to a competing comparable LFP cell [13]. The NMC cell was dimensioned correspondingly based on literature data [48,49]. Data about electrode dimensions and coating thicknesses allowed for a detailed determination of the required mass and corresponding volume of active materials, collector foils, and separator per single round cell. An estimation of the active material void fraction (porosity) was done based on the difference between the density of the unprocessed active material and the actual coating density according to the datasheets [11]. The amount of electrolyte required for cell filling was then calculated by the difference between the inner volume of an 18650 can and the volume of all battery components (cathode, anode, and separator, including the void due to porosity of the active material). Table 4 provides the key performance parameters of the compared battery cells, whereas more details about the battery layout and dimensioning are provided in Table S5 of the SM. The battery model was considered to represent the battery as specified in the underlying datasheets. Batteries can be designed for different purposes (high power/high energy), what affects the electrode thicknesses and thus material balances. However, such a detailed battery model is out of the scope of the present study. Table 4. Performance parameters per single 18650 battery cell. Specific Capacity 0.15 Voltage 3.2 Act. mat. mass 12.69 Capacity Energy Density 0.16 [50] 3.2 12.32 0.30 [50] 0.17 3.2 3.7 5.60 13.68 SIB Cathode LFP Cathode NCM Unit Anode 0.24 3.2 8.88 Anode Cathode Anode 0.30 Ah/g 3.7 V 7.09 g Wh/cell Wh/kg 6.09 138.8 6.31 143.1 9.97 208.0PDF Image | Exploring the Economic Potential of Sodium-Ion Batteries

PDF Search Title:

Exploring the Economic Potential of Sodium-Ion BatteriesOriginal File Name Searched:

Exploring_the_Economic_Potential_of_Sodium-Ion_Bat.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |