PDF Publication Title:

Text from PDF Page: 003

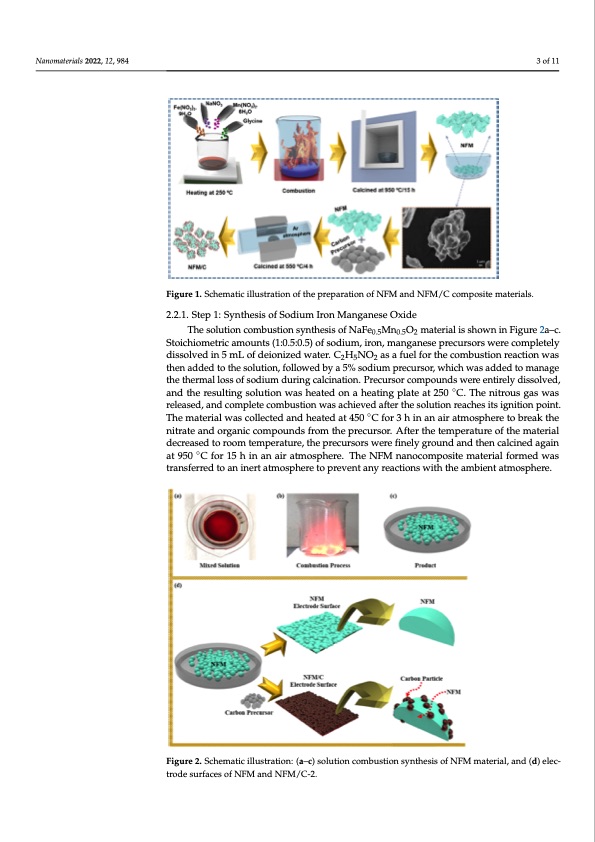

Nanomaterials 2022, 12, 984 Nanomaterials 2022, 12, 984 3 of 11 Nanomaterials 2022, 12, 984 at 950 ◦C for 15 h in an air atmosphere. The NFM nanocomposite material formed was ground and then calcined again at 950 °C for 15 h in an air atmosphere. The NFM nano- 0.5 0.5 2 Sct.oSicthoiochmioetmriectarimcoaumnotsu(n1t:s0.(51::0.5.5):0o.f5s)oodfiusmod,iiuromn,,imroan,gmanaensgeapnresceurpsroercsuwrseorrescwomerpelectoemly- then added to the solution, followed by a 5% sodium precursor, which was added to manage tion was then added to the solution, followed by a 5% sodium precursor, which was added the thermal loss of sodium during calcination. Precursor compounds were entirely dissolved, to manage the thermal loss of sodium during calcination. Precursor compounds were en- and the resulting solution was heated on a heating plate at 250 ◦C. The nitrous gas was tirely dissolved, and the resulting solution was heated on a heating plate at 250 °C. The released, and complete combustion was achieved after the solution reaches its ignition point. nitrous gas was released, and complete combustion was achieved after the solution The material was collected and heated at 450 ◦C for 3 h in an air atmosphere to break the reaches its ignition point. The material was collected and heated at 450 °C for 3 h in an air nitrate and organic compounds from the precursor. After the temperature of the material atmosphere to break the nitrate and organic compounds from the precursor. After the decreased to room temperature, the precursors were finely ground and then calcined again temperature of the material decreased to room temperature, the precursors were finely 4 of 12 transferred to an inert atmosphere to prevent any reactions with the ambient atmosphere. composite material formed was transferred to an inert atmosphere to prevent any reac- tions with the ambient atmosphere. 3 of 12 Figure 1. Schematic illustration of the preparation of NFM and NFM/C composite materials. Figure 1. Schematic illustration of the preparation of NFM and NFM/C composite materials. dissolvedin5mLofdeionizedwater.CHNO asafuelforthecombustionreactionwas pletely dissolved in 5 mL of deionized 2wa5ter. C2 2H5NO2 as a fuel for the combustion reac- 22.2.2.1.1..Sttep1:: Syntthesiis off SodiiumIIrronManganeesseeOxiidee ThheessoolulutitoionncocommbbuustsitoinonsysnytnhtehseisiosfoNf NaFaeFe0M.5Mnn0O.5O2maateteriraial lisishshoowwnnininFiFgiugruer2ea2–ac–. Figure 2. Schematic illustration: (a–c) solution combustion synthesis of NFM material, and (d) elec- Figure 2. Schematic illustration: (a–c) solution combustion synthesis of NFM material, and (d) elec- ttrrodesurfaceessooffNNFMFManadnNdFNMF/MC-/2.C-2. 2.2.2. Step 2: Preparation of NaFe0.5Mn0.5O2/C Composite The NFM/carbon composite was prepared by a facile single-step solid-state method, followed by pyrolysis. Typically, 2 g of as-synthesized NFM was added to a specific amount of 2-methylamidazole and ground for approximately 45 min to achieve proper mixing. Then, the NFM/C-containing precursors were calcined at 550 °C for 4 h in argonPDF Image | NaFe0 Nanocomposite as a Cathode for Sodium-Ion Batteries

PDF Search Title:

NaFe0 Nanocomposite as a Cathode for Sodium-Ion BatteriesOriginal File Name Searched:

nanomaterials-12-00984-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |