PDF Publication Title:

Text from PDF Page: 010

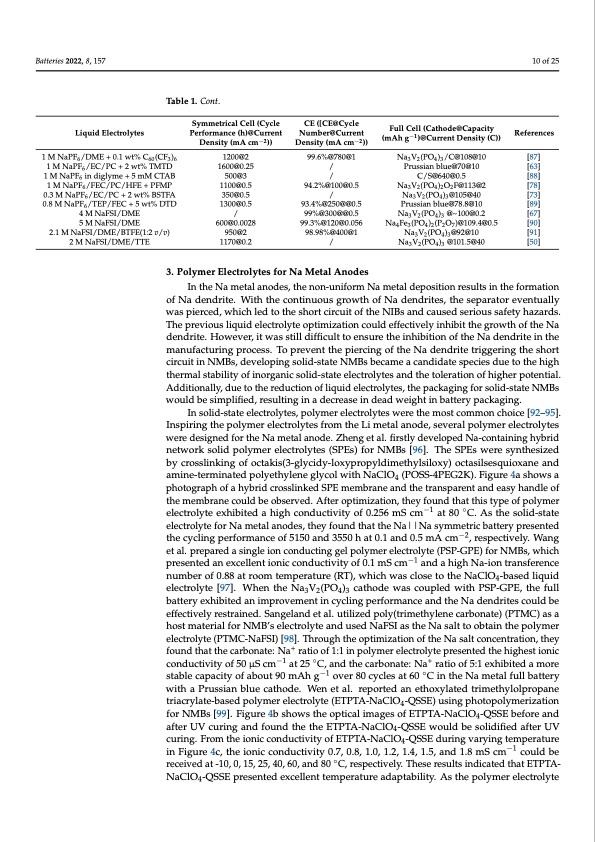

Batteries 2022, 8, 157 10 of 25 Table 1. Cont. Symmetrical Cell (Cycle CE ([CE@Cycle Number@Current Density (mA cm−2)) 99.6%@780@1 / / 94.2%@100@0.5 / 93.4%@250@@0.5 99%@300@@0.5 99.3%@120@0.056 98.98%@400@1 / Full Cell (Cathode@Capacity (mAh g−1)@Current Density (C)) Liquid Electrolytes 1 M NaPF6/DME + 0.1 wt% C60(CF3)6 1 M NaPF6/EC/PC + 2 wt% TMTD 1 M NaPF6 in diglyme + 5 mM CTAB 1 M NaPF6/FEC/PC/HFE + PFMP 0.3 M NaPF6/EC/PC + 2 wt% BSTFA 0.8 M NaPF6/TEP/FEC + 5 wt% DTD 4 M NaFSI/DME 5 M NaFSI/DME 2.1 M NaFSI/DME/BTFE(1:2 v/v) 2 M NaFSI/DME/TTE Performance (h)@Current Density (mA cm−2)) 1200@2 1600@0.25 500@3 1100@0.5 350@0.5 1300@0.5 / 600@0.0028 950@2 1170@0.2 References Na3V2(PO4)3/C@108@10 [87] Prussian blue@70@10 [63] C/S@640@0.5 [88] Na3V2(PO4)2O2F@113@2 [78] Na3V2(PO4)3@105@40 [73] Prussian blue@78.8@10 [89] Na3V2(PO4)3 @~100@0.2 [67] Na4Fe3(PO4)2(P2O7)@109.4@0.5 [90] Na3V2(PO4)3@92@10 [91] Na3V2(PO4)3 @101.5@40 [50] 3. Polymer Electrolytes for Na Metal Anodes In the Na metal anodes, the non-uniform Na metal deposition results in the formation of Na dendrite. With the continuous growth of Na dendrites, the separator eventually was pierced, which led to the short circuit of the NIBs and caused serious safety hazards. The previous liquid electrolyte optimization could effectively inhibit the growth of the Na dendrite. However, it was still difficult to ensure the inhibition of the Na dendrite in the manufacturing process. To prevent the piercing of the Na dendrite triggering the short circuit in NMBs, developing solid-state NMBs became a candidate species due to the high thermal stability of inorganic solid-state electrolytes and the toleration of higher potential. Additionally, due to the reduction of liquid electrolytes, the packaging for solid-state NMBs would be simplified, resulting in a decrease in dead weight in battery packaging. In solid-state electrolytes, polymer electrolytes were the most common choice [92–95]. Inspiring the polymer electrolytes from the Li metal anode, several polymer electrolytes were designed for the Na metal anode. Zheng et al. firstly developed Na-containing hybrid network solid polymer electrolytes (SPEs) for NMBs [96]. The SPEs were synthesized by crosslinking of octakis(3-glycidy-loxypropyldimethylsiloxy) octasilsesquioxane and amine-terminated polyethylene glycol with NaClO4 (POSS-4PEG2K). Figure 4a shows a photograph of a hybrid crosslinked SPE membrane and the transparent and easy handle of the membrane could be observed. After optimization, they found that this type of polymer electrolyte exhibited a high conductivity of 0.256 mS cm−1 at 80 ◦C. As the solid-state electrolyte for Na metal anodes, they found that the Na||Na symmetric battery presented the cycling performance of 5150 and 3550 h at 0.1 and 0.5 mA cm−2, respectively. Wang et al. prepared a single ion conducting gel polymer electrolyte (PSP-GPE) for NMBs, which presented an excellent ionic conductivity of 0.1 mS cm−1 and a high Na-ion transference number of 0.88 at room temperature (RT), which was close to the NaClO4-based liquid electrolyte [97]. When the Na3V2(PO4)3 cathode was coupled with PSP-GPE, the full battery exhibited an improvement in cycling performance and the Na dendrites could be effectively restrained. Sangeland et al. utilized poly(trimethylene carbonate) (PTMC) as a host material for NMB’s electrolyte and used NaFSI as the Na salt to obtain the polymer electrolyte (PTMC-NaFSI) [98]. Through the optimization of the Na salt concentration, they found that the carbonate: Na+ ratio of 1:1 in polymer electrolyte presented the highest ionic conductivity of 50 μS cm−1 at 25 ◦C, and the carbonate: Na+ ratio of 5:1 exhibited a more stable capacity of about 90 mAh g−1 over 80 cycles at 60 ◦C in the Na metal full battery with a Prussian blue cathode. Wen et al. reported an ethoxylated trimethylolpropane triacrylate-based polymer electrolyte (ETPTA-NaClO4-QSSE) using photopolymerization for NMBs [99]. Figure 4b shows the optical images of ETPTA-NaClO4-QSSE before and after UV curing and found the the ETPTA-NaClO4-QSSE would be solidified after UV curing. From the ionic conductivity of ETPTA-NaClO4-QSSE during varying temperature in Figure 4c, the ionic conductivity 0.7, 0.8, 1.0, 1.2, 1.4, 1.5, and 1.8 mS cm−1 could be received at -10, 0, 15, 25, 40, 60, and 80 ◦C, respectively. These results indicated that ETPTA- NaClO4-QSSE presented excellent temperature adaptability. As the polymer electrolytePDF Image | Recent Development for Sodium Metal Batteries

PDF Search Title:

Recent Development for Sodium Metal BatteriesOriginal File Name Searched:

batteries-08-00157-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |