PDF Publication Title:

Text from PDF Page: 045

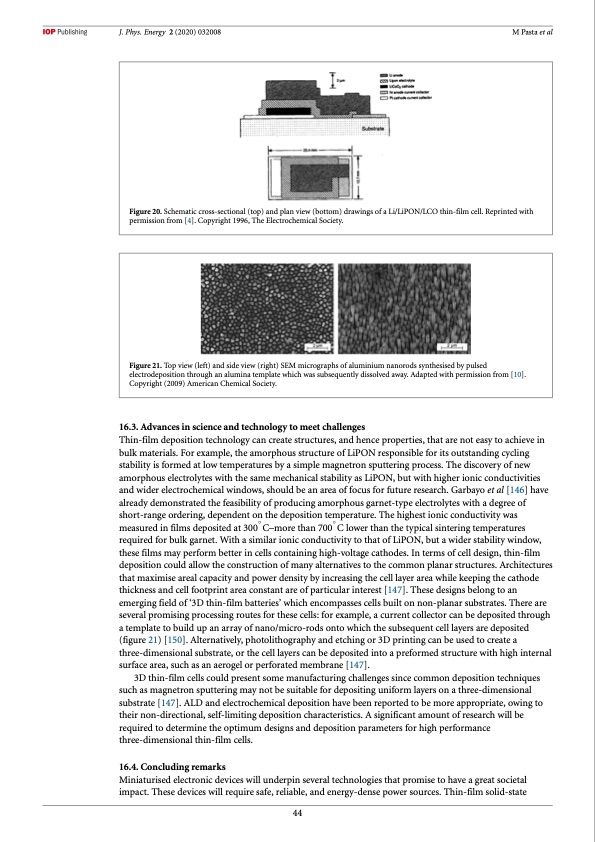

J. Phys. Energy 2 (2020) 032008 M Pasta et al Figure 20. Schematic cross-sectional (top) and plan view (bottom) drawings of a Li/LiPON/LCO thin-film cell. Reprinted with permission from [4]. Copyright 1996, The Electrochemical Society. Figure 21. Top view (left) and side view (right) SEM micrographs of aluminium nanorods synthesised by pulsed electrodeposition through an alumina template which was subsequently dissolved away. Adapted with permission from [10]. Copyright (2009) American Chemical Society. 16.3. Advances in science and technology to meet challenges Thin-film deposition technology can create structures, and hence properties, that are not easy to achieve in bulk materials. For example, the amorphous structure of LiPON responsible for its outstanding cycling stability is formed at low temperatures by a simple magnetron sputtering process. The discovery of new amorphous electrolytes with the same mechanical stability as LiPON, but with higher ionic conductivities and wider electrochemical windows, should be an area of focus for future research. Garbayo et al [146] have already demonstrated the feasibility of producing amorphous garnet-type electrolytes with a degree of short-range ordering, dependent on the deposition temperature. The highest ionic conductivity was ◦◦ measured in films deposited at 300 C–more than 700 C lower than the typical sintering temperatures required for bulk garnet. With a similar ionic conductivity to that of LiPON, but a wider stability window, these films may perform better in cells containing high-voltage cathodes. In terms of cell design, thin-film deposition could allow the construction of many alternatives to the common planar structures. Architectures that maximise areal capacity and power density by increasing the cell layer area while keeping the cathode thickness and cell footprint area constant are of particular interest [147]. These designs belong to an emerging field of ‘3D thin-film batteries’ which encompasses cells built on non-planar substrates. There are several promising processing routes for these cells: for example, a current collector can be deposited through a template to build up an array of nano/micro-rods onto which the subsequent cell layers are deposited (figure 21) [150]. Alternatively, photolithography and etching or 3D printing can be used to create a three-dimensional substrate, or the cell layers can be deposited into a preformed structure with high internal surface area, such as an aerogel or perforated membrane [147]. 3D thin-film cells could present some manufacturing challenges since common deposition techniques such as magnetron sputtering may not be suitable for depositing uniform layers on a three-dimensional substrate [147]. ALD and electrochemical deposition have been reported to be more appropriate, owing to their non-directional, self-limiting deposition characteristics. A significant amount of research will be required to determine the optimum designs and deposition parameters for high performance three-dimensional thin-film cells. 16.4. Concluding remarks Miniaturised electronic devices will underpin several technologies that promise to have a great societal impact. These devices will require safe, reliable, and energy-dense power sources. Thin-film solid-state 44PDF Image | 2020 roadmap on solid-state batteries

PDF Search Title:

2020 roadmap on solid-state batteriesOriginal File Name Searched:

Pasta_2020_J_Phys_Energy_2_032008.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |