PDF Publication Title:

Text from PDF Page: 016

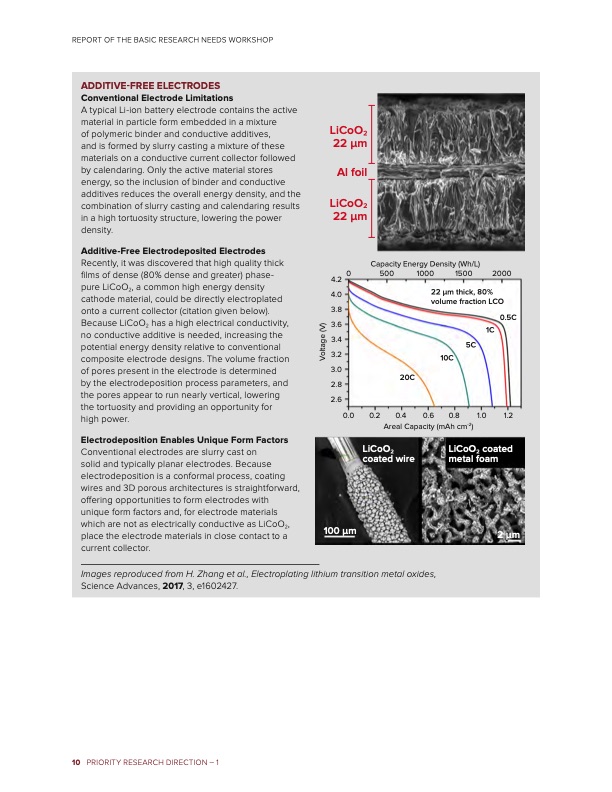

REPORT OF THE BASIC RESEARCH NEEDS WORKSHOP ADDITIVE-FREE ELECTRODES Conventional Electrode Limitations A typical Li-ion battery electrode contains the active material in particle form embedded in a mixture of polymeric binder and conductive additives, and is formed by slurry casting a mixture of these materials on a conductive current collector followed by calendaring. Only the active material stores energy, so the inclusion of binder and conductive additives reduces the overall energy density, and the combination of slurry casting and calendaring results in a high tortuosity structure, lowering the power density. Additive-Free Electrodeposited Electrodes Recently, it was discovered that high quality thick films of dense (80% dense and greater) phase- pure LiCoO2, a common high energy density cathode material, could be directly electroplated onto a current collector (citation given below). Because LiCoO2 has a high electrical conductivity, no conductive additive is needed, increasing the potential energy density relative to conventional composite electrode designs. The volume fraction of pores present in the electrode is determined by the electrodeposition process parameters, and the pores appear to run nearly vertical, lowering the tortuosity and providing an opportunity for high power. Electrodeposition Enables Unique Form Factors Conventional electrodes are slurry cast on solid and typically planar electrodes. Because electrodeposition is a conformal process, coating wires and 3D porous architectures is straightforward, offering opportunities to form electrodes with unique form factors and, for electrode materials which are not as electrically conductive as LiCoO2, place the electrode materials in close contact to a current collector. LiCoO2 22 μm Al foil LiCoO 22 μm 4.2 0 4.0 3.8 3.6 3.4 3.2 3.0 2.8 2.6 0.0 100 μm 2 Capacity Energy Density (Wh/L) 500 1000 1500 2000 22 μm thick, 80% volume fraction LCO 0.5C 1C 5C 10C LiCoO2 coated wire LiCoO2 coated metal foam 2 μm 20C 0.2 0.4 0.6 Areal Capacity (mAh cm-2) 0.8 1.0 1.2 Images reproduced from H. Zhang et al., Electroplating lithium transition metal oxides, Science Advances, 2017, 3, e1602427. 10 PRIORITY RESEARCH DIRECTION – 1 Voltage (V)PDF Image | Next Generation Electrical Energy Storage

PDF Search Title:

Next Generation Electrical Energy StorageOriginal File Name Searched:

BRN-NGEES_rpt-low-res.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |