PDF Publication Title:

Text from PDF Page: 051

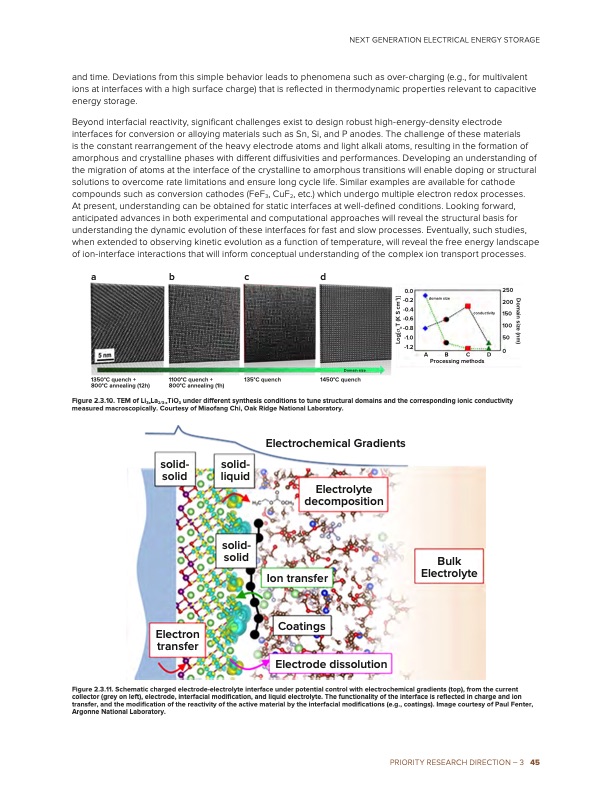

and time. Deviations from this simple behavior leads to phenomena such as over-charging (e.g., for multivalent ions at interfaces with a high surface charge) that is reflected in thermodynamic properties relevant to capacitive energy storage. Beyond interfacial reactivity, significant challenges exist to design robust high-energy-density electrode interfaces for conversion or alloying materials such as Sn, Si, and P anodes. The challenge of these materials is the constant rearrangement of the heavy electrode atoms and light alkali atoms, resulting in the formation of amorphous and crystalline phases with different diffusivities and performances. Developing an understanding of the migration of atoms at the interface of the crystalline to amorphous transitions will enable doping or structural solutions to overcome rate limitations and ensure long cycle life. Similar examples are available for cathode compounds such as conversion cathodes (FeF3, CuF2, etc.) which undergo multiple electron redox processes. At present, understanding can be obtained for static interfaces at well-defined conditions. Looking forward, anticipated advances in both experimental and computational approaches will reveal the structural basis for understanding the dynamic evolution of these interfaces for fast and slow processes. Eventually, such studies, when extended to observing kinetic evolution as a function of temperature, will reveal the free energy landscape of ion-interface interactions that will inform conceptual understanding of the complex ion transport processes. abcd 1350°C quench + 800°C annealing (12h) 1100°C quench + 800°C annealing (1h) 135°C quench Domain size 1450°C quench Figure 2.3.10. TEM of Li3xLa2/3-xTiO3 under different synthesis conditions to tune structural domains and the corresponding ionic conductivity measured macroscopically. Courtesy of Miaofang Chi, Oak Ridge National Laboratory. NEXT GENERATION ELECTRICAL ENERGY STORAGE 0.0 -0.2 -0.4 -0.6 -0.8 -1.0 -1.2 250 200 conductivity 150 100 50 0 Processing methods domain size ABCD solid- solid- solid liquid solid- solid Electron transfer Electrolyte decomposition Electrochemical Gradients Ion transfer Coatings Electrode dissolution Bulk Electrolyte Figure 2.3.11. Schematic charged electrode-electrolyte interface under potential control with electrochemical gradients (top), from the current collector (grey on left), electrode, interfacial modification, and liquid electrolyte. The functionality of the interface is reflected in charge and ion transfer, and the modification of the reactivity of the active material by the interfacial modifications (e.g., coatings). Image courtesy of Paul Fenter, Argonne National Laboratory. PRIORITY RESEARCH DIRECTION – 3 45 Domain size (nm) Log[σbT (K S cm-1)]PDF Image | Next Generation Electrical Energy Storage

PDF Search Title:

Next Generation Electrical Energy StorageOriginal File Name Searched:

BRN-NGEES_rpt-low-res.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |