PDF Publication Title:

Text from PDF Page: 128

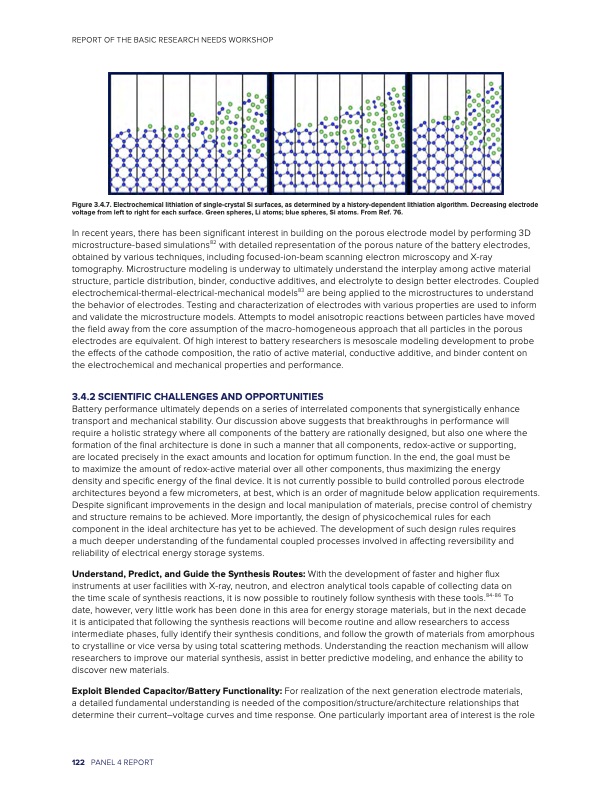

REPORT OF THE BASIC RESEARCH NEEDS WORKSHOP Figure 3.4.7. Electrochemical lithiation of single-crystal Si surfaces, as determined by a history-dependent lithiation algorithm. Decreasing electrode voltage from left to right for each surface. Green spheres, Li atoms; blue spheres, Si atoms. From Ref. 76. In recent years, there has been significant interest in building on the porous electrode model by performing 3D microstructure-based simulations82 with detailed representation of the porous nature of the battery electrodes, obtained by various techniques, including focused-ion-beam scanning electron microscopy and X-ray tomography. Microstructure modeling is underway to ultimately understand the interplay among active material structure, particle distribution, binder, conductive additives, and electrolyte to design better electrodes. Coupled electrochemical-thermal-electrical-mechanical models83 are being applied to the microstructures to understand the behavior of electrodes. Testing and characterization of electrodes with various properties are used to inform and validate the microstructure models. Attempts to model anisotropic reactions between particles have moved the field away from the core assumption of the macro-homogeneous approach that all particles in the porous electrodes are equivalent. Of high interest to battery researchers is mesoscale modeling development to probe the effects of the cathode composition, the ratio of active material, conductive additive, and binder content on the electrochemical and mechanical properties and performance. 3.4.2 SCIENTIFIC CHALLENGES AND OPPORTUNITIES Battery performance ultimately depends on a series of interrelated components that synergistically enhance transport and mechanical stability. Our discussion above suggests that breakthroughs in performance will require a holistic strategy where all components of the battery are rationally designed, but also one where the formation of the final architecture is done in such a manner that all components, redox-active or supporting, are located precisely in the exact amounts and location for optimum function. In the end, the goal must be to maximize the amount of redox-active material over all other components, thus maximizing the energy density and specific energy of the final device. It is not currently possible to build controlled porous electrode architectures beyond a few micrometers, at best, which is an order of magnitude below application requirements. Despite significant improvements in the design and local manipulation of materials, precise control of chemistry and structure remains to be achieved. More importantly, the design of physicochemical rules for each component in the ideal architecture has yet to be achieved. The development of such design rules requires a much deeper understanding of the fundamental coupled processes involved in affecting reversibility and reliability of electrical energy storage systems. Understand, Predict, and Guide the Synthesis Routes: With the development of faster and higher flux instruments at user facilities with X-ray, neutron, and electron analytical tools capable of collecting data on the time scale of synthesis reactions, it is now possible to routinely follow synthesis with these tools.84-86 To date, however, very little work has been done in this area for energy storage materials, but in the next decade it is anticipated that following the synthesis reactions will become routine and allow researchers to access intermediate phases, fully identify their synthesis conditions, and follow the growth of materials from amorphous to crystalline or vice versa by using total scattering methods. Understanding the reaction mechanism will allow researchers to improve our material synthesis, assist in better predictive modeling, and enhance the ability to discover new materials. Exploit Blended Capacitor/Battery Functionality: For realization of the next generation electrode materials, a detailed fundamental understanding is needed of the composition/structure/architecture relationships that determine their current–voltage curves and time response. One particularly important area of interest is the role 122 PANEL 4 REPORTPDF Image | Next Generation Electrical Energy Storage

PDF Search Title:

Next Generation Electrical Energy StorageOriginal File Name Searched:

BRN-NGEES_rpt-low-res.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |