PDF Publication Title:

Text from PDF Page: 144

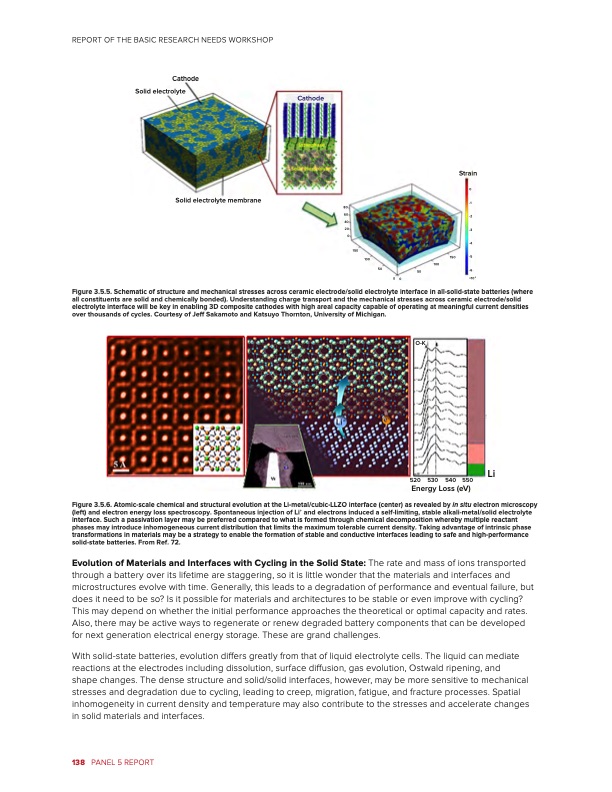

REPORT OF THE BASIC RESEARCH NEEDS WORKSHOP Cathode Solid electrolyte Solid electrolyte membrane Cathode Figure 3.5.5. Schematic of structure and mechanical stresses across ceramic electrode/solid electrolyte interface in all-solid-state batteries (where all constituents are solid and chemically bonded). Understanding charge transport and the mechanical stresses across ceramic electrode/solid electrolyte interface will be key in enabling 3D composite cathodes with high areal capacity capable of operating at meaningful current densities over thousands of cycles. Courtesy of Jeff Sakamoto and Katsuyo Thornton, University of Michigan. O-K 80 60 40 20 0 150 100 50 50 Strain 0 -1 -2 -3 -4 150 -5 100 -6 ×10-3 0 0 Li Energy Loss (eV) Figure 3.5.6. Atomic-scale chemical and structural evolution at the Li-metal/cubic-LLZO interface (center) as revealed by in situ electron microscopy (left) and electron energy loss spectroscopy. Spontaneous injection of Li+ and electrons induced a self-limiting, stable alkali-metal/solid electrolyte interface. Such a passivation layer may be preferred compared to what is formed through chemical decomposition whereby multiple reactant phases may introduce inhomogeneous current distribution that limits the maximum tolerable current density. Taking advantage of intrinsic phase transformations in materials may be a strategy to enable the formation of stable and conductive interfaces leading to safe and high-performance solid-state batteries. From Ref. 72. Evolution of Materials and Interfaces with Cycling in the Solid State: The rate and mass of ions transported through a battery over its lifetime are staggering, so it is little wonder that the materials and interfaces and microstructures evolve with time. Generally, this leads to a degradation of performance and eventual failure, but does it need to be so? Is it possible for materials and architectures to be stable or even improve with cycling? This may depend on whether the initial performance approaches the theoretical or optimal capacity and rates. Also, there may be active ways to regenerate or renew degraded battery components that can be developed for next generation electrical energy storage. These are grand challenges. With solid-state batteries, evolution differs greatly from that of liquid electrolyte cells. The liquid can mediate reactions at the electrodes including dissolution, surface diffusion, gas evolution, Ostwald ripening, and shape changes. The dense structure and solid/solid interfaces, however, may be more sensitive to mechanical stresses and degradation due to cycling, leading to creep, migration, fatigue, and fracture processes. Spatial inhomogeneity in current density and temperature may also contribute to the stresses and accelerate changes in solid materials and interfaces. 138 PANEL 5 REPORT 520 530 540 550PDF Image | Next Generation Electrical Energy Storage

PDF Search Title:

Next Generation Electrical Energy StorageOriginal File Name Searched:

BRN-NGEES_rpt-low-res.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |